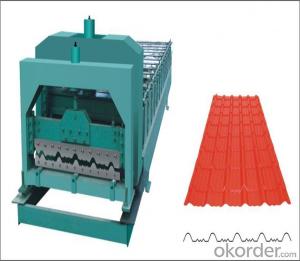

Step Tile Cold Roll forming machine with ISO Quality Sytem

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Step Tile Cold Roll forming machine

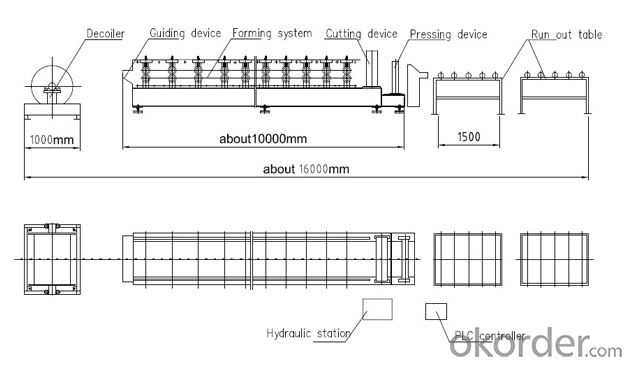

Technical data of step tile roll forming machine

Suitable Material | Q235 color steel sheet;0.4-0.6mm | |

Working speed | About 3.0m/min | |

Step distanc | adjustable according to requirement (>=250mm) | |

Power Requirement | Main motor power: 5.5 Kw(Depend on final design) | |

Hydraulic station power: 5.5Kw(Depend on final design) | ||

Material of forming rollers | No.45 steel, plated with chrome on surface. | |

Material of cutter,pressing die | Cr12 mould steel with quench treatment, HRC58-60 | |

Material of shaft | High quality 45# steel, Dia. is 72mm. | |

Shaft diameter | 72mm | |

Controlling system | Mitsubishi PLC & converter | |

Total weight of machine | About 10500KGS | |

Size of machine installation | About 18m×1.8m× 1.5m (Depend on final design) | |

Layout drawing of machine

Product application of step tile roll forming machine:

The colored steel tiles produced by step tile roll forming machine look beautiful, elegant and noble. They are widely used as the roof of garden, factory, hotel, exhibition center and villa,etc.

Our Step Tile Cold Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines. |

- Q: What are the types of machine tools?

- Machinable range is very wide, rotary body, spiral body, plane, groove, gear and so on.

- Q: What is rocker machine, gantry machine? Are these two types of machines belonging to the same classification method? Are there any other machine tools in this category?

- Various machine tools have a variety of machine tool classification methods, there is unity, but a variety of machine tools have a variety of machine tool classification.

- Q: The difference between the lathes 6140, 6240

- The difference is that 6140 is a horizontal lathe, 240 is a saddle lathe, the other is no different.

- Q: What can a CNC lathe do?

- 1 to 2 years on the almost a little advanced machine tools on the master's ability and technical requirements are high.

- Q: CNC lathes 6140 and 6040 What is the difference

- 1 for single-axis automatic lathes, 2 for multi-axis automatic semi-automatic lathes, 3 for hexagonal lathes, 4 for crankshafts and camshaft lathes, 5 for vertical lathes, 6 for lathes,

- Q: Why is the CNC lathe so precise, what is it?

- 2: CNC lathe screw feed units are um level even smaller, (1mm = 1000um)

- Q: Lathe C6140 meaning

- And ordinary lathe, 7 said multi-knife and profiled lathe, 8 said wheel, shaft, ingot, roller and shovel lathe, 9 said other lathe.

- Q: What is the main work of CNC machine tools?

- high flexibility. Processing objects change, generally only need to change the NC program, reflecting the good adaptability, can greatly save production preparation time. In the CNC machine tools, based on the composition can be more flexible automated manufacturing system-FMS.

- Q: What is the risk of CNC lathes

- The above potential pollution, generally in accordance with the work process to do, do a good job protection, little effect.

- Q: What is the role of a CNC machine lock switch?

- Through the arithmetic processing by the numerical control device issued a variety of control signals, control machine action, according to the drawings of the shape and size, automatically the parts processed out.

Send your message to us

Step Tile Cold Roll forming machine with ISO Quality Sytem

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches