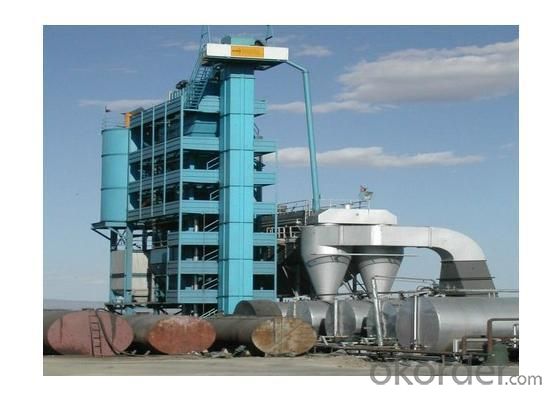

Stationary Asphalt Mixing Plant HMAP-ST2000 160t/h

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 Sets per Year set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Equipment Composition of 160t/h HMAP-ST2000 Stationary Asphalt Mixing Plant

1. Aggregate Supplying & Cold Bin:

--- Cold bin / Belt Feeder / #1ST Belt Conveyor

2. Aggregate Heating Unit:

--- #2nd Belt Conveyor / Dryer / Burner / Blower / Hot Elevator

3. Main Frame:

--- Screen / Hot bin / Weighing Unit / Mixer / Asphalt Spray Pump

4. Dust collecting unit:

--- Dust Chamber / Exhaust Fan / Bag Filter / Chimney Dust Recycling Screw Conveyor / Air Compressor & Piping

5. Filler Supplying Unit:

--- Filler Silo / Screw Conveyor / Filler Elevator

6. Asphalt Tank:

--- AP Tank / AP Feeding Pump & Piping / Hot Oil Heater / Hot Oil Circulation Pump & Piping

7. Bunker-C/Diesel Tank / Heating Unit:

--- Bunker-C/Diesel Tank / Bunker-C & Diesel Piping.

8. Control System Operation Room:

--- Control Panel / Printer / C.C TV / Power Panel / Electric Wiring.

- Q: What are the small concrete mixers

- Now the market is commonly used for small mixers with JZC350, JZC500, JDY350, JDY500, JS500, JS750, JS1000

- Q: What are the pros and cons of a concrete mixer?

- If the concrete is not used, it is recommended to buy concrete from the concrete station Small mixers can't keep up with the efficiency, plus the cost of labor Better to buy from the concrete station

- Q: Concrete mixers need to be aware of which things

- The concrete mixer driver must be familiar with the performance and operation of the machine, and wear the protective equipment according to the regulation. Article 2: before work should check whether the transmission clutch and brake is flexible and reliable, climbing rope fights with and without broken wires, transmission components such as the mixer of the big gear, pulley guard is in good condition, whether the motor grounding is good, confirmed rear can work. Article 3: the driver is not allowed to leave the job in the operation of the machine, and when the blender is running, it is forbidden to reach into the mixing bowl with an axe, spade or any other object. Article 4: when the hopper arises, no one shall pass or stay in the hopper. If it is necessary to check and repair, the power should be cut off, and the bucket will be held in the back of the link. Article 5: when the feeding operation is strictly prohibited, the operator will put the head into the hopper and the rack to inspect the loading condition. Article 6: if you need to go into the mixing tube for cleaning, you should disconnect the power supply, remove the fuse, and put the lock on the switch box, or be guarded by a special person.

- Q: How many square concrete can be produced in an hour of concrete mixer

- The blender can produce 50L concrete at a time, which is 0.05 square concrete. The blender is about 20 times before the concrete is produced. Mixer, it is a kind of with the blade shaft rotating in the cylinder or tank, will a variety of raw materials mixing, make it become a kind of mixture or machine suitable for consistency. The blender is divided into several kinds, such as strong mixing machine, single-sleeper shaft mixer, two-sleeper shaft mixer and so on. Note: mixers and automatic feeding machines must be cleaned, especially in winter, which can prolong life. A blender is a mixer because the mixing machine is commonly used to mix and stir all kinds of dry mortar

- Q: Is the concrete mixer and mortar mixer a machine

- The mortar mixer is the machine which mixes the cement, the sand and the aggregate with the water and mixed the mortar. It consists mainly of mixing, loading and unloading mechanism, water supply system, original motive, transmission mechanism, frame and supporting device. Mortar mixer equipment can meet the performance requirements of dry mortar, dry material, adhesive powder production needs, such as: putty powder, powder coating, masonry mortar, plaster mortar, insulation mortar, decorative mortar needed by the system and so on all kinds of dry powder mortar; And it has many advantages such as small area, little investment, quick results and easy operation. Working principle: when mixed machine work, inside the machine material subjected to two opposite direction of the rotor, with complex movement, the blades to drive the material aspect counterclockwise along the machine slot wall, on the one hand, drive material turning around, overlapping the two rotor shape floating zone, within the region, regardless of the shape of the material, size, and density, can make material floating instant weightlessness, which makes the material in the machine groove omni-directional continuous loop turn staggered shear each other, so as to achieve the effect of rapid mixing soft.

- Q: How is the concrete mixer cleaned

- When the blender is finished, rinse the water immediately, but you can't wash it if you don't clean it immediately

- Q: Common type of concrete mixer

- The type of concrete mixer used, the method of work: strong mode; Drum. The size of the mix is divided into: 250 (0.25 cubic); 350 (0.35 cubic meters); 500 (0.5 cubic); 750 (0.75 cubic per square).

- Q: How much concrete the concrete mixer can stir at a time

- 350-concrete mixer is a double conical turning out of the feed mixer, and the plastic and semi-dry hard concrete of 60 mm. Stirring when the mixer is turning, and automatically when reversing. Each can be mixed with concrete 0.35 cubic meters. Depending on the size of the concrete, the amount of cement used varies.

- Q: How does a concrete mixer operate

- If the machine is relatively new, the button will have, it's going to go up, go down, automatically add water, add water by hand, mix it up, mix it up, stop, vibrate

- Q: What is the difference between a concrete mixer, a JL type and a JW type?

- The jw-375 concrete mixer is a turbo-reinforced concrete mixer, which is used for hard and semi-dry concrete. The main body of this mixer consists of the frame, the feeding system, the mixing system, the water supply system, the control device and the transmission mechanism.

1. Manufacturer Overview

| Location | Liaoning, China |

| Year Established | 2001 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | South America Eastern Europe Southeast Asia Africa Mid East South Asia Domestic Market |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | DALIAN |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Spanish, Portuguese, Arabic, French, Russian, Hindi |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Stationary Asphalt Mixing Plant HMAP-ST2000 160t/h

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 60 Sets per Year set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches