Step Tile Roll forming machine with CE certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

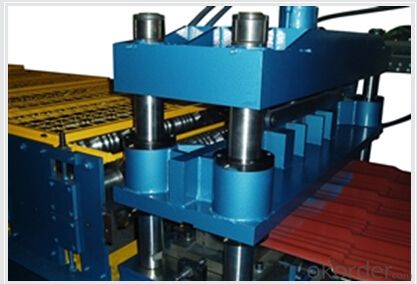

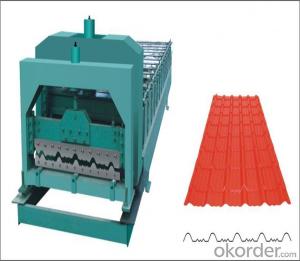

Step Tile Roll forming machine

Technical data of step tile roll forming machine

Suitable Material | Q235 color steel sheet;0.4-0.6mm | |

Working speed | About 3.0m/min | |

Step distanc | adjustable according to requirement (>=250mm) | |

Power Requirement | Main motor power: 5.5 Kw(Depend on final design) | |

Hydraulic station power: 5.5Kw(Depend on final design) | ||

Material of forming rollers | No.45 steel, plated with chrome on surface. | |

Material of cutter,pressing die | Cr12 mould steel with quench treatment, HRC58-60 | |

Material of shaft | High quality 45# steel, Dia. is 72mm. | |

Shaft diameter | 72mm | |

Controlling system | Mitsubishi PLC & converter | |

Total weight of machine | About 10500KGS | |

Size of machine installation | About 18m×1.8m× 1.5m (Depend on final design) | |

Layout drawing of machine

Our Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines. |

![]()

- Q: Production of composite flooring required complete sets of equipment and raw materials

- This is the conventional board, if it is the kind of big chamfering board have to have a machine cleaning machine!

- Q: What machinery is required to process solid wood flooring?

- Fourth, measuring equipment, transportation and storage tools

- Q: What equipment does bamboo flooring need?

- Dry: boiling water boiled bamboo, moisture content is high, can not directly into the suppression, the water content must be controlled to 12% or less;

- Q: Full production of wood flooring equipment

- Equipment generally need to plan a plane, double-end milling a heavy sanding machine, a thick plate sanding machine, sand coating machine primer 3-4, putty machine 2,

- Q: Do not use organic solvents for wood flooring? What are all? What is the use?

- Most of the current water-based glue is used, there is no organic solvent, there are several paint, pre-painted floor (that is, the production line of the paint floor) are used UV paint, the solid content of high, organic

- Q: What are the equipment for producing wood flooring?

- Also known as wood flooring, is directly processed into solid wood floor.

- Q: What machinery do you need to produce solid wood flooring?

- The paint process is generally divided, painted, four times primer + twice painted finish, or four times primer + leaching paint, if you need wear, the primer also need to add again wear bottom.

Send your message to us

Step Tile Roll forming machine with CE certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches