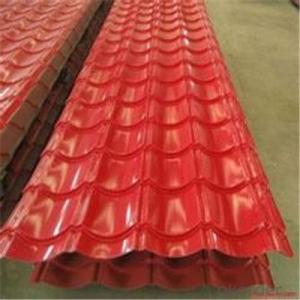

Prepainted Galvanized Corrugated Steel Plate Sheet:roofing sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard package for export |

| Delivery Detail: | 15 days after receipt the deposit or Original L/C |

Specifications

Prepainted roofing steel sheets

1. Thickness: 0.15mm---1.5mm

2. Width:800,900,1200,1220,1250mm

3.can be prepainted

Commodity | color coated galvanized steel plate |

Material | Galvanized steel sheet Galvalume steel sheet Pre-painted galvanized sheet |

Coating | PE,PVDF,galvanized(30-300g),galvalume (AZ80) |

Model No. | YX25-207-828 |

Sheet Thickness | 0.15---1.5mm |

Sheet Peak Height | 25mm |

Sheet Peak Spacing | 207mm |

Width | 800mm,900mm,1000mm |

Length | any length,according to the transportation,generally less than 12m |

Color | Standard color: red,blue,white grey Special color: according to RAL color |

Characteristic | 1 weatherproof 2 heating insulation 3 fireproof 4 anti-rust 5 sound insulation 6 long life span: more than 25 years

|

Packing | Plastic film,pallet or as your requests |

Delivery time | 15 days |

Payment | T/T,L/C |

Images:

- Q: What are the different sheet metal finishing techniques for steel sheets?

- Some of the different sheet metal finishing techniques for steel sheets include deburring, grinding, polishing, sanding, and painting.

- Q: What are the standard dimensions for steel sheets?

- The specific type and grade of steel being used can cause variation in the standard dimensions for steel sheets. Generally, steel sheets are found in standard sizes of 4 feet by 8 feet or 4 feet by 10 feet. These dimensions are widely used in the construction industry and can be easily obtained from steel suppliers. Moreover, steel sheets can be tailored to specific dimensions to meet the requirements of a particular project. It is crucial to seek guidance from a steel supplier or manufacturer to ascertain the precise dimensions available for the desired type of steel sheet.

- Q: How do steel sheets perform in terms of weather resistance?

- Steel sheets possess exceptional weather resistance properties, renowned for their ability to withstand diverse weather conditions like rain, snow, and wind. This is attributed to their composition and the protective coatings they bear. Notably, steel sheets can endure extreme temperatures, both hot and cold, without experiencing any considerable deterioration or harm. Furthermore, their resistance to corrosion is highly pronounced, rendering them an optimal choice for outdoor applications and locations exposed to high humidity or saltwater. Consequently, the weather resistance possessed by steel sheets guarantees their long-lasting and robust nature, establishing them as a dependable option for a wide range of construction and industrial purposes.

- Q: What are the common industries that use steel sheets?

- The common industries that use steel sheets include construction, automotive, aerospace, manufacturing, energy, and shipbuilding.

- Q: Are the steel sheets suitable for solar panel mounting?

- Yes, steel sheets are suitable for solar panel mounting. Steel is a strong and durable material that can provide a stable and secure base for solar panels. It has the necessary strength to support the weight of the panels and withstand various weather conditions. Additionally, steel sheets can be easily fabricated and customized to fit the specific requirements of the solar panel installation. Overall, using steel sheets for solar panel mounting can ensure a reliable and long-lasting foundation for the panels.

- Q: Are steel sheets suitable for food processing facilities?

- Yes, steel sheets are highly suitable for food processing facilities. Steel is a preferred material for food processing due to its numerous beneficial properties. Firstly, steel sheets are non-porous, meaning they do not absorb or retain moisture, bacteria, or odors, making them highly hygienic. This characteristic prevents the growth of bacteria and minimizes the risk of contamination, ensuring the safety and quality of the food being processed. Secondly, steel sheets are easy to clean and maintain. They can withstand frequent cleaning and sanitization procedures without corroding or degrading. Stainless steel, in particular, is resistant to corrosion, rust, and staining, making it an ideal choice for food processing facilities where cleanliness is of utmost importance. Furthermore, steel sheets have excellent durability and strength, ensuring longevity and reliability in food processing operations. They can withstand heavy use, high temperatures, and mechanical stresses that are common in food processing facilities. Steel sheets also have a high melting point, making them fire-resistant, which is crucial for the safety of the facility. Additionally, steel sheets are versatile and can be fabricated into various shapes and sizes to suit the specific needs of food processing facilities. They can be used for walls, floors, work surfaces, storage units, and equipment, providing a seamless and integrated solution for the facility's infrastructure. In summary, steel sheets are highly suitable for food processing facilities due to their hygienic properties, ease of cleaning, durability, and versatility. They contribute to maintaining a safe and sanitary environment, which is essential for the production of high-quality and uncontaminated food products.

- Q: What is the difference between a hot rolled and cold rolled stainless steel sheet?

- The manufacturing process and resulting properties distinguish hot rolled stainless steel sheets from cold rolled ones. Hot rolled sheets are created by heating stainless steel to a high temperature and rolling it through a series of rollers to achieve the desired thickness. This method is typically used for larger sheets and results in a rougher surface finish. Additionally, hot rolled sheets are known for their inherent strength and malleability, making them suitable for various applications that require structural integrity. In contrast, cold rolled stainless steel sheets are produced by cooling the stainless steel to a lower temperature and passing it through rollers at room temperature. This process yields a smoother and more refined surface finish compared to hot rolled sheets. Cold rolled sheets are commonly preferred for precision-demanding applications such as automotive components, appliances, and electronic devices. Regarding mechanical properties, hot rolled stainless steel sheets generally possess a higher yield strength and lower ductility when compared to cold rolled sheets. This can be attributed to the grain structure formed during the hot rolling process, resulting in a more coarse and less uniform microstructure. Conversely, cold rolled sheets have a finer grain structure and higher ductility, making them more suitable for forming and bending operations. To summarize, the primary differences between hot rolled and cold rolled stainless steel sheets lie in the manufacturing process and the resulting properties. Hot rolled sheets exhibit a rougher surface finish, higher strength, and lower ductility, whereas cold rolled sheets possess a smoother surface finish, higher ductility, and are often preferred for precision-demanding and forming applications.

- Q: What is the difference between a galvanized and stainless steel sheet?

- Both galvanized and stainless steel sheets are utilized in various applications, but there are notable distinctions between the two materials. One significant difference is their resistance to corrosion. Galvanized steel sheets are coated with zinc to shield them from rust and corrosion, making them ideal for outdoor applications or environments with high humidity or moisture. Conversely, stainless steel sheets are composed of chromium and other alloys, granting them superior corrosion resistance. They can endure exposure to chemicals, acids, and saltwater, making them suitable for highly corrosive environments. Another disparity lies in their appearance. Galvanized steel sheets possess a characteristic silver-gray color due to the zinc coating. Over time, the zinc coating can acquire a dull, weathered appearance. In contrast, stainless steel sheets possess a distinct, shiny appearance that can vary based on the applied finish. This makes stainless steel sheets more visually appealing and suitable for applications where aesthetics matter. In terms of strength and durability, stainless steel sheets tend to surpass galvanized steel sheets. Stainless steel has a higher tensile strength, enabling it to withstand more force or pressure before breaking. Additionally, stainless steel is more resistant to dents and scratches compared to galvanized steel. Cost is another factor to consider when choosing between galvanized and stainless steel sheets. Generally, galvanized steel sheets are more cost-effective than stainless steel sheets. This makes them a viable option for applications where corrosion resistance is not of utmost importance. Conversely, stainless steel sheets are pricier due to the higher cost of raw materials and the additional processing required to create the stainless steel alloy. To summarize, the main distinctions between galvanized and stainless steel sheets lie in their corrosion resistance, appearance, strength, and cost. Galvanized steel sheets offer decent corrosion resistance at a lower cost, while stainless steel sheets provide superior corrosion resistance, strength, and a more appealing appearance at a higher price point.

- Q: How do steel sheets handle chemical exposure?

- Steel sheets are renowned for their outstanding ability to resist chemical exposure. They exhibit a high level of resistance to corrosion and can endure exposure to a wide array of chemicals, including acids, alkalis, solvents, and other substances that cause corrosion. This exceptional resistance is primarily attributed to the formation of a protective oxide layer, known as patina, on the surface of the steel. This layer acts as a barrier, preventing the chemicals from attacking the steel. Moreover, steel sheets can be further safeguarded by applying various protective coatings, such as galvanization, epoxy coatings, or powder coatings. These coatings provide an extra layer of protection and enhance the steel's resistance to chemical exposure. However, it is important to acknowledge that the resistance of steel sheets to chemical exposure may vary based on the specific type and concentration of the chemicals involved. Highly concentrated or aggressive chemicals may still lead to some degree of corrosion or damage to the steel surface over time. Hence, it is crucial to carefully consider the specific chemical environment and select the appropriate grade of steel and protective coating to ensure optimum resistance to chemical exposure. In summary, steel sheets are a dependable and durable choice for applications that demand resistance to chemical exposure. With careful selection and maintenance, they can effectively withstand diverse chemical environments and deliver long-lasting performance.

- Q: How do steel sheets handle thermal conductivity?

- Steel sheets have high thermal conductivity, which means they can efficiently transfer heat. This property allows steel sheets to quickly and evenly distribute heat across their surface, making them suitable for various applications such as heat transfer systems, cookware, and building materials.

Send your message to us

Prepainted Galvanized Corrugated Steel Plate Sheet:roofing sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords