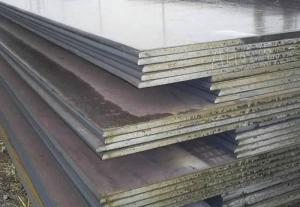

Steel Sheets Hot Rolled Good Quality for Export

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Description

Hot rolled steel is a high temperature heating and rolled steel,

Hot rolled steel

Its strength is not high, but enough to meet our use, its plasticity, good weldability so we compare common;Cold rolling is ordinary hot-rolled steel after strong drawing more than stage of strain hardening steel, its strength is very high, but the toughness and weldability poor, hard and brittle

2. Main Features

Hot rolled product features: hot-rolled products have high strength, good toughness, easy to processing molding and good weldability and other excellent properties, and therefore is widely used in ship, automobile, Bridges, buildings, machinery, pressure vessels and other manufacturing industries.

3. Excellent Product Image

4. Application

Our hot-rolled steel coil and sheet are applied to a wide range of uses such as automobile, electrical appliance, machinery manufacturing, container manufacturing, shipbuilding, bridge, pipeline, and receive high acclaim from our customers for its excellent quality.

5. FAQ

1.Q: Do you have attended any exhibition?

A: We almost go to Canton Fair and Overseas Exhibitions every year.

2. Q: How to guarantee the quality of the products?

A: We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. Q: How long can we receive the product after purchase?

A: Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

Why choose us?

Pre-sale Service

1. Sample can be offered with sample charge and courier fee by buyer's side.

2. We have full stock,and can deliver within short time.Many styles for your choices.

3. OEM and ODM order are accepted, Any kind of logo printing or design are available.

4. Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you

5. All of our products are produce by our professional workman and we have our high-work-effect foreign trust-worthy sales team.

6. We have 18 years' experience of design, manufacture and sell lingerie, we cherish every order from our honor.

After you choose

1. Count the most efficient shipping cost and make invoice to you at once.

2. Check quality again, then send out to you at 1-2 working day after your payment.

3. Email you the tracking no, and help to chase the parcels until it arrive you.

- Q: How are steel sheets tested for hardness?

- Steel sheets are tested for hardness using various methods, one of the most common being the Rockwell hardness test. In this test, a small indenter, usually a diamond or a hardened steel ball, is pressed into the surface of the steel sheet with a known force. The depth of penetration is measured and converted into a hardness value using a standardized scale. Another method used is the Brinell hardness test, where a hardened steel ball is pressed into the surface of the steel sheet under a specific load. The diameter of the indentation is measured and used to calculate the hardness value. Additionally, there is the Vickers hardness test, which utilizes a pyramid-shaped diamond indenter. The test is similar to the Rockwell test, but instead of measuring the depth of penetration, the test measures the diagonal length of the indentation to determine the hardness value. These hardness tests provide valuable information about the mechanical properties of steel sheets, such as their resistance to deformation and wear. The results of these tests help ensure that the steel sheets meet the required specifications and can be used in various applications where hardness is a critical factor.

- Q: Can steel sheets be drilled?

- Yes, steel sheets can be drilled.

- Q: What is the difference between a perforated and woven steel sheet?

- A perforated steel sheet is a metal sheet that has been punched with a pattern of holes, allowing for ventilation, drainage, or visibility. On the other hand, a woven steel sheet is a mesh-like structure created by interweaving individual steel wires, providing strength, filtration, or screening capabilities. The main difference lies in the manufacturing process and the resulting design, with perforated sheets having distinct punched holes and woven sheets having a continuous mesh pattern.

- Q: How are steel sheets protected during storage in outdoor environments?

- Steel sheets are often protected during storage in outdoor environments through several measures. One common method is the application of a protective coating on the surface of the sheets. This coating acts as a barrier, preventing moisture and other environmental factors from coming into direct contact with the steel. The coating can be in the form of paint, varnish, or a specialized corrosion-resistant substance. In addition to the protective coating, steel sheets may also be covered with a plastic wrap or tarpaulin to provide an extra layer of protection. This helps to shield the sheets from rain, snow, and other weather conditions that could potentially cause rust or corrosion. Furthermore, proper stacking and storage techniques are crucial in protecting steel sheets. They should be stored in a dry and well-ventilated area, preferably on pallets or racks to keep them off the ground. Adequate spacing between the stacks allows for air circulation, reducing the risk of moisture buildup. Regular maintenance and inspection are essential to ensure the continued protection of steel sheets during storage in outdoor environments. The protective coating should be periodically checked for any signs of damage or wear, and any necessary touch-ups or reapplications should be promptly carried out. By implementing these protective measures, steel sheets can be safeguarded against the harsh elements present in outdoor environments, ensuring their longevity and preserving their quality.

- Q: Can steel sheets be used for construction equipment?

- Yes, steel sheets can be used for construction equipment. Steel is a versatile and durable material that is commonly used in the construction industry for various applications, including equipment fabrication. Steel sheets can be shaped, welded, and formed into different components and structures needed for construction equipment, such as bulldozers, cranes, excavators, and dump trucks. Steel's high strength-to-weight ratio makes it suitable for heavy-duty equipment, providing the necessary strength and stability while keeping the weight manageable. Additionally, steel is resistant to corrosion, which is crucial for construction equipment exposed to harsh environmental conditions. Overall, steel sheets are a popular choice for construction equipment due to their strength, durability, and versatility.

- Q: How can steel plates with a thickness of 1MM be welded?

- The seam is also called the wheel welding equipment for the production, mainly uses fuel exhaust pipe seal. The principle is similar to that of spot welding. The difference is that the output current is uninterrupted.

- Q: How do steel sheets handle bending or flexing?

- Steel sheets are known for their excellent strength and rigidity, making them highly resistant to bending or flexing. The inherent properties of steel, such as its high tensile strength and stiffness, allow it to withstand substantial external forces without deforming. Steel sheets can handle bending or flexing to a certain extent without compromising their structural integrity, making them suitable for a wide range of applications. When steel sheets are subjected to bending or flexing forces, they undergo a process known as elastic deformation. This means that the steel will temporarily change shape under the applied load, but it will return to its original form once the load is removed. This elasticity is due to the crystalline structure of steel, which allows it to absorb and distribute the stress evenly throughout its structure. However, it is important to note that steel sheets do have a limit to their bending or flexing capabilities. Beyond a certain point, the applied load can cause the steel to undergo plastic deformation, which results in permanent changes to its shape. This can lead to the formation of cracks or fractures in the material. The maximum amount of bending or flexing that steel sheets can tolerate before experiencing plastic deformation is determined by factors such as the thickness of the sheet, the grade and type of steel used, and the specific application requirements. To enhance the flexibility of steel sheets, certain processes such as cold rolling or annealing can be employed. Cold rolling involves passing the steel sheet through rollers at ambient temperature, which not only increases its strength but also improves its ability to withstand bending or flexing forces. Annealing, on the other hand, involves heating the steel to a specific temperature and then cooling it slowly to relieve internal stresses, making it more ductile and less prone to cracking. In conclusion, steel sheets are highly capable of handling bending or flexing due to their inherent strength, rigidity, and elasticity. However, it is essential to consider the specific application requirements and the limitations of the steel sheet to ensure its performance and longevity.

- Q: How are steel sheets transported?

- Steel sheets are typically transported using various methods, depending on the quantity, size, and destination. One common method is by truck, where the steel sheets are loaded onto flatbed trailers or enclosed trucks. This allows for easy transportation and flexibility in reaching different locations. For larger quantities or long-distance transportation, steel sheets can be transported by rail. They are usually loaded onto specialized railcars designed to securely hold and transport heavy loads. Rail transportation is efficient for long distances and can handle larger volumes of steel sheets. In some cases, steel sheets may also be transported by sea. They are loaded onto shipping containers or directly onto ships designed for bulk cargo. This method is usually used for international shipments or when transporting large quantities of steel sheets across long distances. Regardless of the transportation method, it is crucial to ensure that the steel sheets are properly secured and protected during transit to prevent damage or loss. This may involve using straps, chains, or other securing devices to hold the sheets in place and protect them from shifting or external factors such as weather conditions. Overall, the transportation of steel sheets requires careful planning and coordination to ensure safe and efficient delivery to their intended destination.

- Q: Can steel sheets be used for manufacturing shipping containers?

- Indeed, the utilization of steel sheets in the production of shipping containers is possible. Steel, being a robust and durable material, offers exceptional structural resilience, rendering it an ideal choice for the construction of shipping containers. Typically, steel sheets are employed in fabricating the container's walls, roof, and floor, guaranteeing its ability to endure the demanding conditions of transportation and safeguard the goods contained within. Moreover, steel exhibits resistance to diverse weather conditions, corrosion, and pests, thereby establishing it as a trustworthy option for the manufacturing of shipping containers.

- Q: How do steel sheets perform in tensile strength?

- Steel sheets have high tensile strength, meaning they are able to withstand large amounts of stretching or pulling forces without breaking or deforming.

Send your message to us

Steel Sheets Hot Rolled Good Quality for Export

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords