Steel Sheet for Boiler and Pressure Vessel AISI/ASTM A36

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description of steel sheet:

Stainless steel types 304 and 304L.Type 304 stainless steel material is a kind of common stainless steel materials, corrosion prevention is b

2.Features of steel sheet:

304 stainless steel has good corrosion and corrosion resistance and good resistance to intergranular corrosion. For oxidizing acid, obtained in the experiment, the concentration of 65% or less under the boiling temperature of nitric acid, 304stainless steel has a strong corrosion resistance. To most organic and inorganic acid and alkali solution with good corrosion resistance ability.

All stainless stock can be delivered mirror polished if required

3.Data of steel sheet:

Type | Grade | Standard | Specification(mm) |

Carbon and Low Alloy Structure Steel

| Q195/Q215(A,B),Q275(A,B,C,D) | GB/T3274,GB/T700 | 6-130*1500-4100 |

Q345(A,B,C,D,E) | GB/T1591 | 6-140*1500-4100 | |

Q390/Q420 (A,B,C,D,E) | |||

SS330/SS400/SS490/SS540 | JIS G3101 | 6-120*1500-4100 | |

S235(JR,J0,J2)/S275(JR,J0,J2)/S355(JR, J0,J2,K2) | EN10025-2 | 8-50*1500-4100 | |

St37/St52 series | DIN 17100 | ||

A36, A572 GR.42-GR.65 A709 GR.36-GR.50 | ASTM A36/A36M, ASTM A572/A572M ASTM A709/A709M | 8-100*1500-4100 | |

S275/S355(N,NL) | EN 10025-3 |

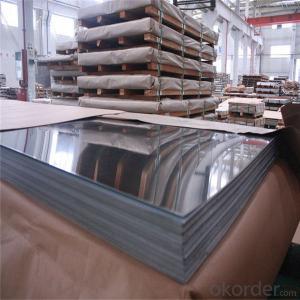

4.Image of steel sheet:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the rental costs for steel sheet piles?

- The utility model has the advantages of high strength, easy to break into the hard soil layer; construction in deep water, if necessary with the inclined support into a cage. The utility model has the advantages of good waterproof performance, forming a cofferdam with various shapes according to requirements and repeated use for many times; therefore, the utility model has wide application.

- Q: What are the main applications of steel sheets?

- Steel sheets have a wide range of applications in various industries due to their durability, strength, and versatility. Some of the main applications of steel sheets include: 1. Construction: Steel sheets are widely used in the construction industry for making beams, columns, and structural frames. They provide strength and stability to buildings, bridges, and other infrastructure projects. 2. Automotive industry: Steel sheets are extensively used in the automotive industry for manufacturing vehicle bodies, chassis, and other structural components. They offer high strength and impact resistance, ensuring passenger safety. 3. Manufacturing and machinery: Steel sheets are used in the manufacturing sector for fabricating heavy machinery, equipment, and industrial tools. Their high tensile strength and resistance to wear and tear make them suitable for demanding applications. 4. Appliances and electronics: Steel sheets are commonly used in household appliances like refrigerators, washing machines, and ovens. They provide a sturdy and durable outer casing, protecting the internal components. 5. Energy and power generation: Steel sheets are essential in the power generation industry for constructing power plants, transmission towers, and wind turbines. They can withstand extreme weather conditions and provide structural integrity. 6. Packaging industry: Steel sheets are used for manufacturing packaging materials like cans, drums, and containers. They ensure the safety and preservation of goods during transportation and storage. 7. Aerospace and defense: Steel sheets find applications in the aerospace and defense sectors for manufacturing aircraft parts, missiles, and armored vehicles. Their high strength-to-weight ratio is crucial for these industries. 8. Furniture and interior design: Steel sheets are used in the production of furniture, fixtures, and decorative elements. They offer a modern and sleek appearance while providing durability and stability. Overall, steel sheets are highly versatile and find applications in numerous industries due to their strength, durability, and diverse range of properties.

- Q: Are the steel sheets suitable for automotive body repairs?

- Yes, steel sheets are suitable for automotive body repairs. Steel is a commonly used material in the automotive industry due to its high strength and durability. It is able to withstand impact and provides structural integrity to the vehicle's body. Steel sheets are often used in repairing damaged or dented body panels, allowing for a seamless repair that restores the vehicle's original shape and strength. Additionally, steel sheets can be easily manipulated and shaped to match the specific contours of the vehicle, ensuring a precise and accurate repair.

- Q: Who knows the wire width of the steel mesh?

- Steel net is diamond, respectively from the left and right (up or down) with two curved metal strips, the two metal strips are generally not the same thickness, the thickness is the stem width, the width is less than the thickness of material.

- Q: What are the different profile options available for steel sheets?

- There are several different profile options available for steel sheets, each serving different purposes and offering unique benefits. Some of the most common profile options include: 1. Plain Sheet: This is the simplest and most basic profile option, with a flat surface and no additional features. It is commonly used for general purposes where aesthetics are not a priority. 2. Corrugated Sheet: Corrugated steel sheets have a series of parallel ridges and grooves, creating a wavy pattern. This profile provides extra strength and rigidity, making it ideal for roofing, cladding, and fencing applications. The ridges also enhance water shedding, preventing water accumulation on the surface. 3. Ribbed Sheet: Ribbed steel sheets have a series of raised parallel ridges or ribs running along the length of the sheet. This profile offers improved strength and load-bearing capacity, making it suitable for applications that require structural integrity, such as mezzanine floors, decking, and industrial flooring. 4. Perforated Sheet: Perforated steel sheets have a pattern of holes punched into them, allowing for ventilation, light transmission, and drainage. This profile is commonly used in architectural designs, façades, acoustics, and filtration systems. 5. Tread Plate: Tread plates have a raised pattern of lines or diamonds embossed on the surface. This profile provides extra grip and slip resistance, making it ideal for industrial flooring, stairs, ramps, and walkways. 6. Expanded Metal: Expanded metal sheets are created by cutting and stretching a flat sheet, resulting in a pattern of diamond-shaped openings. This profile offers excellent ventilation, visibility, and security, making it suitable for applications such as grilles, screens, fences, and enclosures. 7. Lipped Sheet: Lipped steel sheets have an edge or lip bent at a 90-degree angle along one or more sides. This profile provides added strength and stiffness, making it commonly used for framing, shelving, and edge protection. These are just a few examples of the different profile options available for steel sheets. The choice of profile depends on the specific requirements of the application, such as strength, durability, aesthetics, and functionality.

- Q: Can steel sheets be used for food storage containers?

- Yes, steel sheets can be used for food storage containers. Steel is a widely used material in the food industry due to its durability, resistance to corrosion, and ability to maintain the quality and freshness of food. Steel sheets can be fabricated into containers that are safe, hygienic, and suitable for storing various types of food.

- Q: What are the different standards and certifications for steel sheets?

- Steel sheets must adhere to numerous standards and certifications in order to ensure their quality and compliance with industry requirements. Some of the well-known ones are: 1. ASTM International: To establish the mechanical and chemical properties of steel sheets, ASTM A1008/A1008M provides a standard specification for cold-rolled, carbon, structural, high-strength low-alloy steel sheets with improved formability. 2. American Iron and Steel Institute (AISI): Various standards are offered by AISI for different types of steel sheets, such as AISI 4130, AISI 4140, AISI 4340, etc. These standards outline the chemical composition, mechanical properties, and heat treatment requirements for specific steel sheet types. 3. International Organization for Standardization (ISO): ISO has developed standards like ISO 3574, ISO 630, and ISO 4998 to cover dimensional tolerances, mechanical properties, and technical delivery conditions for specific steel sheet grades. 4. European Committee for Standardization (CEN): CEN has defined requirements for cold-rolled, hot-rolled, and high-strength steel sheets through standards like EN 10130, EN 10025, and EN 10149 respectively. These standards encompass aspects such as chemical composition, mechanical properties, and surface finish. 5. Japan Industrial Standards (JIS): JIS standards like JIS G 3141, JIS G 3131, and JIS G 3132 are widely used for cold-rolled, hot-rolled, and hot-rolled high-strength steel sheets respectively. They specify the mechanical properties, chemical composition, and dimensional tolerances of steel sheets. Furthermore, steel sheet manufacturers can obtain various certifications to demonstrate their adherence to specific quality and environmental management systems. Some widely recognized certifications in the steel industry include ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System), and OHSAS 18001 (Occupational Health and Safety Management System). These certifications guarantee that manufacturing processes and products meet the required standards while being produced in an environmentally sustainable and safe manner.

- Q: What's the difference between a spray plate and a colored steel plate?

- Then the color, not the quality of the domestic coatings products, fully meet the demand, the high price of imported coating reduces the competitiveness of skin colour in the plastic film is still dependent on imports, lack of high-grade color coating thickness, functional, high strength, rich color coated plate. Therefore, the choice of color steel plate is relatively narrow, and basically are low-end products, but more convenient, you can buy directly!

- Q: What are the applications of steel sheets?

- Steel sheets have a wide range of applications due to their durability, strength, and versatility. They are commonly used in construction for roofing, flooring, and wall cladding. Steel sheets are also used in manufacturing processes for automobiles, appliances, and machinery. Additionally, they are utilized in the production of containers, pipes, and furniture. Overall, steel sheets find extensive use in various industries due to their excellent mechanical properties and ability to withstand harsh conditions.

- Q: Can steel sheets be used for conveyor belts?

- Yes, steel sheets can be used for conveyor belts. Steel sheets are often used as the base material for conveyor belts due to their strength, durability, and resistance to high temperatures. They provide excellent support for carrying heavy loads and are commonly found in industries such as mining, automotive, and manufacturing.

Send your message to us

Steel Sheet for Boiler and Pressure Vessel AISI/ASTM A36

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords