Steel Sandwich Panels with Excellent Quality Ceramic Fiber Core

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

newly-designed ceramic fiber sandwich panel

1. widely application

2. DIN JIS standard

3. long life span

Ceramic fiber sandwich panel:

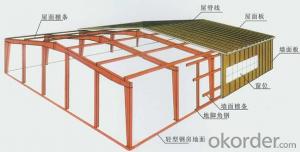

Ceramic fiber sandwich panel is shaped by rock wool and steel panel through automatic production line without further jointing at the site, it has good properities of heat preservation and sound insulation, heat insulation, fireproof.

Usage: Widely used for the roof, exterior walls and internal partitions of industrial and civil buildings which have requirements of fire, sound insulation and thermal insulation, especially for the fire controlling projects.

Construction:

1)The upper and lower surfaces: Adopted by galvanized color steel plate, thickness 0.4-0.8mm. According to customer's specific need, it also can be used Galvanized color steel plate or aluminum plate. After rolling by the mould machinery the steel plate is stuck with the rock wool.

2)Rock wool core material: The density of rock wool block is 120kg/m3, it is staggered and rolled out with its fiber direction perpendicular to the upper and lower surface of the sandwich panel, the rock wool is closely-phase jointed filling the entire vertical and horizontal section of the sandwich panel. The rock wool between the blocks and steel sheet is shaped into one whole block by high-intensity foam, sophisticated process ensures high-density rock wool insulation between the inner body and metal plate can produce a very strong adhesion, which made rock wool sandwich panel has a strong stiffness.

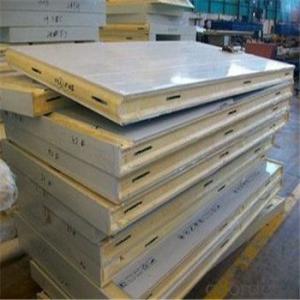

Product Specifications:

1) Width <950mm/1150mm, length <120000mm can be fixed according to design requirements and transport conditions

2) Thickness: 50mm, 75mm, 100mm

Features:

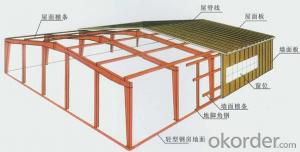

1) Good Stiffness: After the polystyrene core material is shaped as a whole, and through heating and pressurizing, it is stuck to the surface of the steel plate. After figuration the sandwich panel has excellent integrity; And there is pressured waves on the upper surface on roof panel, the overall stiffness is better than other similar materials, by connected and fixed with the purlin the stiffness of the wall and roof panel is improved greatly.

2) Special deduction method: The access of the rock wool roof panel is connected by buckling, protecting the seam from leaking and save the installing parts of panel.

3) Strong and reasonable fixing method: The roof panel is fixed by the special made tapping M6 and jointed with the purlin thus it can resist typhoon and other the external force, the tapping is in the wave crest of the surface of the roof with special waterproof structure, moreover due to the special structures of the tapping, for example, there is a plastic cap on the screw cap to avoid leakage.

4) Short installation: No more process on the install site, it can not only keep clean of environment without influencing other production stages but also shorten the time of fixing back plate.

5) Anti-scratching: There is a pressure-sensitive adhesive film on the surface of the panel to protect the coating surface from scratching damage.

Advantages:

1) Good fireproof performance: Using rock wool materials, special process and formula, the sandwich panel has good fire performance. Tests showed that it can stand more than 1000 degree of the fire.

2)Good thermal insulation: The insulation thermal conductivity of the rock wool sandwich panel is low as λ = 0.043 W/m2 K,

3) Remarkable sound insulation and absorbtion

Sound insulation: The Rock wool sandwich panel has a significant reduction of noise transfer, it is particularly applied to place where there are regular flights. In addition, the indoor sound from the impact of the rain, hail, etc also decreased after using rock wool roof panel, but also significantly decreased.

According to ISO 717/82 and UNI 8270 / 7 criteria, sound insulation effect of rock wool sandwich panel with density of 100kg/m3 rock wool core material can achieve RW = 29 ~ 30 dB.

- Q: Air conditioning year after the addition of Calvary is not the reason for refrigeration

- Quantitative analysis of the problems exist in the security of the building, in a safe building. In order to solve this problem, you must first understand the specification. However, the specification is not enough, not only to understand the safety load calculation of scaffolding. Please forgive me, I am not here, in the past, it is too much trouble. Construction specifications are specified in this process, try to calculate. Technical specification for safety of fastener type steel pipe scaffold (JGJ130-2001)

- Q: Reinforced concrete and metal sandwich board how much difference

- Light steel plant roof static load can be divided into the following . the roof for the single-layer + cotton insulation, 0.20KN / M. the roof for the double board + insulation cotton, 0.25KN / M. the roof for the foam sandwich panels, if 50 thick, 0.3KN / M2 specific calculation, assuming purlin per meter specific gravity of . the distance is 1.. then converted to 7 / 1.5 = 5 kg or so insulation cotton generally in 1 kg, pull the sub-component 2 kg, single Floor panel 0.5 thick -0.5 * 7.85 = 4 kg then the roof of a single board + insulation cotton, constant load of 5 +1 +2 +4 = 12 kg per square meter of the actual design time to enlarge the point, take a 0.. Otherwise your trial is also very sad.

- Q: What is the difference between the board and the core board? The The

- Cantilevered scaffolding should use biaxial symmetrical section of the steel, which is usually said I-beam models and anchors need to calculate each other, according to the stairs to set the shape

- Q: Color steel room life in general how many years

- The price with the upper and lower color plate thickness, polystyrene bulk density, there are regional differences are related. Specifically you can call the local color steel factory.

- Q: Own balcony capped, with the kind of sandwich panels better, EPS sandwich panels or rock wool sandwich panels, or other kind of sandwich panels?

- First of all you have to steel structure design and construction specifications to understand, have to clear the construction process of steel. The construction plan is mainly applicable. Quality Assurance Measures and Safety Assurance Measures.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient

- Q: How does the wall rock wool sandwich panel be installed?

- the basis for the preparation (the relevant laws and regulations, standards, construction drawings, computing software, etc

- Q: Are sandwich panels suitable for train stations?

- Train stations can benefit from the use of sandwich panels, a construction material consisting of two outer layers and an insulating core. These panels offer excellent thermal insulation, fire resistance, and soundproofing properties, making them an ideal choice for train station applications. The insulation provided by sandwich panels helps to regulate the temperature inside the station, creating a comfortable environment for passengers and staff regardless of external weather conditions. This can result in reduced energy consumption and lower heating or cooling costs. Fire resistance is crucial in train stations, where the risk of fire is a major concern. Sandwich panels are highly fire-resistant, which can help contain and slow down the spread of fire. This provides valuable time for evacuation and firefighting efforts. Sandwich panels also offer excellent soundproofing capabilities, reducing noise transmission in train stations. This creates a more peaceful and comfortable atmosphere for passengers and staff. Furthermore, sandwich panels are lightweight, easy to install, and cost-effective. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are a suitable choice for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, benefiting both passengers and staff.

- Q: Steel structure workshop roof load is the number of specific Please thank you

- General color steel foam sandwich panels. Price in the 45 - 60 yuan / M ? or so.

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- Expandable polystyrene foam board (referred to as polystyrene board, the EPS board). Polystyrene Biscuit Powder Kuba Kawakun Fung Mo foam products are processed intermediate products, with less investment, fast turnover, low energy consumption, occupation of production personnel less, the production of high profit products. At the same time the number of devices less simple operation, strong production flexibility, product quality has a reliable guarantee, and thus the project construction risk is small. EPS board is made of polystyrene (EPS) beads made by foam molding. Polystyrene is invented in the 1950s, polystyrene foam products is a new type of advanced insulation, noise insulation materials. It is light in quality, non-toxic and tasteless, without any pollution. Use is very wide, mainly used for refrigerators, trains, ships, limousines, mobile homes, housing insulation insulation. Instrumentation, porcelain, glass products, home appliances and other packaging. In the construction industry it is an alternative to moisture-proof powder, perlite, asbestos and other insulation materials, is a very wide range of new products, so far there is no one product to replace the market prospects are very broad.

Send your message to us

Steel Sandwich Panels with Excellent Quality Ceramic Fiber Core

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords