Discontinuous or continuous pu sandwich panel production line

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Container |

| Delivery Detail: | 21 days |

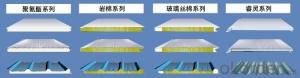

Specifications

1) Light weight

2) Heat insulation

3) Sound Insulation

4) Fireproof

5) CE &ISO Passed

Specification:

| Core material of panel | Polyurethane |

| Core density | 36~40kg/m3 |

| Panel availiable thickness | 50mm,75mm,100mm,120mm,150mm,200mm |

| Material of panels surface | Color plate, Stainless Steel, etc. |

| Surface of panels thickness | 0.3mm~0.8mm |

| Width of the panel | 970mm |

Advantage:

| Heat Preservation | Anti-freezing, heat preserving and environmental friendly |

| Fire Proof | Grade B2 |

| Sound Insulation | Polyurethane has fine sound insulation and sound-absorbing functions |

| Easy to install | No special technical required |

We have best quality, best price and best service. We are welcome all of your inquiry.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Height of 24m below the double scaffold can be flexible connection, but must be used to withstand the tension and pressure structure.

- Q: What are the different types and uses of clean color steel plates?

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed time when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the amount of rain on the big leak, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask!

- Q: Will the use of color steel sandwich panels ceiling package package how much money a square? M14 round steel to do hanging bars, 950 sandwich panels, the main bone 160 * 60 * 20 * 2.5 C steel Is the workshop ceiling, I should quote how much appropriate,

- What are the sub-items of the general project that should be prepared for the special safety program? What should be included in the special programming? The following dangerous parts of the sub-sub-projects and temporary electricity equipment in 5 and above or the total capacity of equipment in the 50kW and above the construction site of temporary electricity construction

- Q: Color steel sandwich board on the price of how much?

- Surface leveling should be able to, but the words come back, multilayer is cheaper than the former! For more information, better advice, free of charge to provide concrete waterproof water leakage II Cao Hao 丨 sell Zhatai Chunjun repair professional and technical advice, from today's repair, tomorrow leak;

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- First of all, the tempered glass can no longer be drilled high and the ancient antecedant for the short hole, will certainly be broken, and do not make the edge of the local force, but also fragile (so use a few bumps to block it The method is not good) should be tempered glass as a whole embedded in a slot, you can in the low side of the welding of a corner, the length of the glass and the same edge, play a block of the role, in addition, usually the tempered glass is not easy to be deformed Damage, but can not make it too much force

- Q: Can sandwich panels be used for ticket booths?

- Yes, sandwich panels can be used for ticket booths. Sandwich panels are versatile and commonly used in construction due to their lightweight, durable, and insulating properties. They can be easily customized to meet specific requirements, making them suitable for ticket booths that need to be portable, weather-resistant, and secure. Additionally, sandwich panels offer good thermal and acoustic insulation, ensuring a comfortable environment for booth attendants and customers.

- Q: Steel structure workshop roof load is the number of specific Please thank you

- Contents The first chapter of the construction site safety technical information management of the main contents and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technical information Four sections of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (the second file box) third (The third file box) Section IV of the safety of the construction organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (sixth file Box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident (the tenth file box ) Section XI Safety signs (eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (the twelfth file box) thirteenth Machinery and equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union labor protection information

- Q: Consult the requirements of the flame retardant 0 standard from which the standard standard, and then ask the next level 0 flame retardant standard self-extinguishing time is how much. More

- Steel pipe is a steel pipe bowl buckle is the connection point like a bowl button is the connection point is a disk above a lot of hole pin is not a national standard thing is not recommended to use

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- Expandable polystyrene foam board (referred to as polystyrene board, the EPS board). Polystyrene Biscuit Powder Kuba Kawakun Fung Mo foam products are processed intermediate products, with less investment, fast turnover, low energy consumption, occupation of production personnel less, the production of high profit products. At the same time the number of devices less simple operation, strong production flexibility, product quality has a reliable guarantee, and thus the project construction risk is small. EPS board is made of polystyrene (EPS) beads made by foam molding. Polystyrene is invented in the 1950s, polystyrene foam products is a new type of advanced insulation, noise insulation materials. It is light in quality, non-toxic and tasteless, without any pollution. Use is very wide, mainly used for refrigerators, trains, ships, limousines, mobile homes, housing insulation insulation. Instrumentation, porcelain, glass products, home appliances and other packaging. In the construction industry it is an alternative to moisture-proof powder, perlite, asbestos and other insulation materials, is a very wide range of new products, so far there is no one product to replace the market prospects are very broad.

- Q: The stove is dedicated to the plastic used for plastic paper

- Fire level and density does not matter, with the lighter point can not fully explain the problem, b1 level to compound gb8624b1 level

Send your message to us

Discontinuous or continuous pu sandwich panel production line

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords