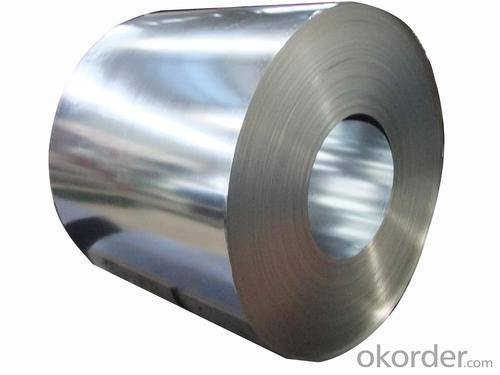

Hot rolled steel coil SS400/A36/Q235 pickled and oiled steel coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, BS, DIN, GB, JIS | Steel Grade: | Q235 | Thickness: | Thickness: 1.8mm-20mm |

| Place of Origin: | China (Mainland) | Technique: | Hot Rolled | Surface Treatment: | Other |

| Application: | Welded pipe, Hardeware and Bicycle manufacturing and so on | Model Number: | Steel Coil | Brand Name: | RGTS |

| Width: | 900mm-2000mm, 900-2000mm | Length: | As your requested | Surface: | black |

| Material Grade: | SS400\Q235\Q345B | Certificate:: | ISO | Package: | in bundles, strapped by strips. Or as customer's requirement |

Packaging & Delivery

| Packaging Details: | 1) Export standard packing in mill 2) Vertical or horizontal, properly packed for ocean freight exportation in one 20' or 40' containers 3) Ocean shipping in bulk-cargo ship |

| Delivery Detail: | within 15-30 days upon receipt original L/C at sight. |

Hot Rolled Pickled and Oiled Steel Coils

1. Production: Hot Rolled Pickled and Oiled Steel Coils

2. Port: Any port,China

3. Category: Minerals & metallurgy

4. Thickness: 1.8mm-20mm

5. Width: 900-2000mm

6. Coil Weight: about 23 tons

7. Material Grade : SS400\Q235\Q345B

8. Technique: Hot Rolled

9. Standard: GB ,JIS

10. Test: With Hydraulic Testing, Eddy Current , Infrared Test

11. Surface:

1) Bared

2) Black Painted (varnish coating)

3) Galvanized

4) Oiled

12. Package: in bundles, strapped by strips. Or as customer’s requirement

13. Sample:

Common products, we can provide freely, for special production,we can depends on negotiation.

14. MOQ: 10 tons

15. Payment: 100% L/C at sight, 30% T/T in advance, and the balance against the copy of B/L or negotiation

16.Delivery time: according to quantity, asap save customer’s time

17. Certificate: ISO

- Q: What is the (balanced) chemical equation for steel?

- This Site Might Help You. RE: Chemical equation for steel? What is the (balanced) chemical equation for steel?

- Q: What are the dimensions of steel coils?

- The dimensions of steel coils can vary depending on the specific product and application, but they typically range in thickness from 0.005 to 0.25 inches and in width from 0.5 to 72 inches. The length of steel coils can also vary, but it is commonly around 100 to 200 feet.

- Q: How are galvanized steel coils different from regular steel coils?

- Galvanized steel coils differ from regular steel coils in terms of their protective coating. Galvanized steel coils are coated with a layer of zinc, which provides a protective barrier against corrosion and rust. This process, known as galvanization, involves dipping the steel coils into a bath of molten zinc or applying zinc onto the surface through various methods. Regular steel coils, on the other hand, do not have this protective coating, making them more susceptible to corrosion and rust. The zinc layer on galvanized steel coils not only acts as a physical barrier but also provides sacrificial protection, meaning that if the coating gets scratched or damaged, the zinc sacrifices itself to protect the underlying steel from corrosion. This makes galvanized steel coils highly durable and suitable for applications that require resistance to harsh environmental conditions, such as outdoor construction projects, automotive manufacturing, and the production of household appliances.

- Q: Basically when i'm older, my dream Job would be, to be to start a steel mill, I've always loved the idea of working in Business and investing in things has always been a hobby of mine. i play games where u invest and make money. all i need is some facts about starting a steel mill?What requirements i need,- How time consuming is it,- How easy is it,- How to get started,- The Perks,- The downsides..how much would it cost to start one, like land, place, iron etc, to get started? also i would need a bank loan, how much money will the bank give me ? 80%??

- Typically, steel mills are worth $20 million to $200 million and are owned by large corporations. Your best bet to own one would be to take over a corporation that already has one. That way you have all the supply lines, customers, experts and other workers already there, too. Stick with investing in going concerns, so you don't need to be an expert in each business to build it up. Get them ready made, learn the details from the people already doing it, then work out ways to improve it. Do not get tempted to borrow even 10c from the scammers who have answered your question. Start saving your real money, reading the financial news, and making small real investments in real stocks.

- Q: I have one and need info about it??....It has a wooden case around the steel necks.and 20 strings,Twin Tens.

- well, it was made sometime before 1981, because that's when Fender quit making 10 string steel guitars. Without any more information than what you've given me, it could be the Pedal 2000, the PS210, or the Artist Dual 10. Fender made steel guitars from the 1950s through 1981, so it could be from any time in there. I hope you have the pedals with it. The 10-string and dual 10-string models were quite expensive in their day. Unfortunately, if you're thinking of reselling it, you're probably not going to get a lot of money for it unless you find a pedal steel player, and like I said, having all the pedals is very important in that case. Anyway, hope this helped. Good luck. If I were you I'd learn to play it. Pedal steel players are always in demand.

- Q: How are steel coils used in the production of construction equipment?

- Steel coils are used in the production of construction equipment as they provide a reliable and cost-effective material for manufacturing various components. These coils are often processed and shaped into specific parts, such as frames, chassis, and heavy-duty structures, which make up the foundation and framework of construction equipment. The high strength and durability of steel coils ensure that the equipment can withstand heavy loads, extreme conditions, and repetitive use, making them essential in the construction industry.

- Q: hey i was looking to buy a khukuri machete by cas iberia. its made of carbon steel but doesnt say which one. anyone that is into knives and all that know how this would hold up and the rust resistance of it? mostly be used for cutting bush and small trees

- Ricki is correct. There is no way to tell how much carbon is present just from the term carbon steel. It comes in a wide range of grades within the general classifications of low, medium, and high carbon steel. What you'll get depends on the quality of the knife. As the carbon content increases, the steel becomes harder, stronger, and more responsive to heat treatment. It also becomes more brittle, so a **very** high carbon steel would not be the best thing for a machete. As Ricki said, plain carbon steels are not rust resistant. However, I have had a carbon steel machete for over 40 years and it's just fine. If you take care of it, it will last.

- Q: like the steel industry and the effects it had on industrial growth, 10 points!

- The single most important important advance in steel production was learning to accurately control carbon content. This was done through the Bessemer Process in which air was blown through molten iron to burn out impurities and excess carbon. Low carbon iron (wrought iron) could be easily worked into shapes. Medium carbon iron could be cast into useful and durable shapes. High carbon steel could be used for structural uses (beams and girders). Adding alloys such as nickel and silicon could produce very tough steels and steels resistant to rust. Adding vanadium to steel engine parts allowed Ford to produce finely machined engines in huge numbers with existing machinery.

- Q: What are the different methods of edge wave correction for steel coils?

- Steel coils often experience edge waves, which are deformations along the edges. To address this issue, various methods are commonly employed. One frequently used technique is edge wave flattening. This involves applying pressure to the coil's edges using hydraulic or mechanical devices. By doing so, any waves or deformations are effectively flattened out. Edge wave flattening can be performed during the coil processing stage or as a separate step after production. Another approach is edge trimming, where the coil's edges are trimmed or cut to remove waves or deformations. Mechanical shearing or laser cutting technology can be utilized for this purpose. Edge trimming not only corrects edge waves but also ensures straight and smooth edges. Tension leveling is another popular method. It involves subjecting the coil to tension forces, which stretch and flatten any waves or deformations. Tension leveling is typically performed during the processing stage and is effective in correcting both edge waves and other surface defects. Roll leveling is also effective for correcting edge waves. This method utilizes a set of rolls to gradually apply pressure to the coil, resulting in the flattening of waves or deformations. Roll leveling is a versatile technique that can address various types of coil defects, including edge waves. Furthermore, advancements in technology have led to the development of automated edge wave correction systems. These systems employ sensors and computer algorithms to detect and correct edge waves in real-time during the coil processing stage. This method ensures precise and consistent correction, reducing the need for manual intervention and improving overall efficiency. In summary, the methods for correcting edge waves in steel coils include edge wave flattening, edge trimming, tension leveling, roll leveling, and automated correction systems. Each method offers unique advantages and can be chosen based on the specific requirements and constraints of the coil processing operation.

- Q: I want to get one of these knives but I am having trouble deciding which is the best overall knife??ThanksSOG Trident tigerSOG Vulcan TantoSOG Bi-Polar (Serrated)Cold Steel ScimitarCold Steel Recon 1

- May be you'll find something amongst those. Again, CQC-7 is a tanto blade and you wont find much use for it for every day use. You can, if you try, but why bother. Also, they today use 154CM steel, pretty good, used to be the top stainless cutlery steel, but rather old now. Hardened to 59-61 HRC. It's not that hard in the end, but will hold considerably better edge than AUS8 steel knives. One thing about CQC-7 it's using liner lock, which is not as strong or convenient as benchmade Axis Lock. Another thing to consider about CQC-7 is it's chisel grind, or single bevel. One side of the blade is flat, the edge is ground only on the opposite side. While this is easier to sharpen, one side vs. 2 sides on conventional blades, it has disadvantages in terms of normal cutting. Takes time to get used to it and you can't use it in certain grips to cut in different direction etc...

Send your message to us

Hot rolled steel coil SS400/A36/Q235 pickled and oiled steel coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords