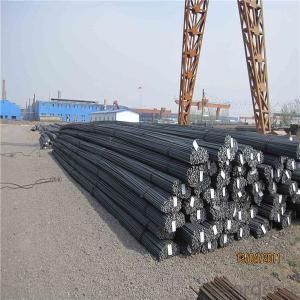

Steel Rebar/Deformed Steel Bar / Iron Rods for Construction/Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Steel Rebar/Deformed Steel Bar / Iron Rods for Construction/Concrete at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Rebar/Deformed Steel Bar / Iron Rods for Construction/Concrete are ideal for structural applications and are widely usedthe construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries

Product Advantages:

OKorder's Steel Rebar/Deformed Steel Bar / Iron Rods for Construction/Concrete are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade:HRB400

Certificates: ISO, SGS, BV, CIQ

Packed: prproduct packed in bundles

Deformed Steel Bar | ||

Diameter (MM) | Cross Sectional Area (MM2) | Theorectical Weight (KG/M) |

6 | 28.27 | 0.222 |

8 | 50.27 | 0.395 |

10 | 78.54 | 0.617 |

12 | 113.1 | 0.888 |

14 | 153.9 | 1.21 |

16 | 201.1 | 1.58 |

18 | 254.5 | 2 |

20 | 314.2 | 2.47 |

22 | 380.1 | 2.98 |

25 | 490.9 | 3.85 |

28 | 615.8 | 4.83 |

32 | 804.2 | 6.31 |

36 | 1018 | 7.99 |

40 | 1257 | 9.87 |

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%) | ||||||

≥400 | ≥570 | ≥14 | ||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q4: How many tons of steel products could be loaded in containers?

A4: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: Can steel rebars be used in the construction of underground parking structures?

- Steel rebars are an effective choice for constructing underground parking structures. They are commonly used in reinforced concrete structures, such as underground parking, to reinforce and provide tensile strength. The rebars are strategically placed within the concrete to enhance its load-bearing capacity, durability, and resistance to cracking or deformation. Steel rebars are ideal for underground parking structures that require strong structural support, thanks to their high strength and ability to withstand heavy loads. To further enhance their resistance to corrosion, protective coatings or stainless steel rebars can be applied, which is particularly important in underground environments with moisture and exposure to chemicals. Ultimately, the use of steel rebars is a standard practice in constructing underground parking structures to ensure long-lasting structural integrity.

- Q: Are there any safety precautions when handling steel rebars?

- Yes, there are several safety precautions that should be followed when handling steel rebars. Here are some important measures to consider: 1. Personal Protective Equipment (PPE): Always wear the appropriate PPE, including safety glasses or goggles, gloves, steel-toed boots, and a hard hat. This will protect you from potential hazards such as falling objects, sharp edges, or flying debris. 2. Proper Lifting Techniques: Steel rebars can be heavy and awkward to handle. When lifting, use proper lifting techniques, such as bending at the knees and keeping your back straight. Avoid twisting or jerking motions that could strain your muscles or cause injury. 3. Secure Storage and Handling: Store and stack steel rebars in a stable and secure manner to prevent them from falling or rolling. Use appropriate storage racks or containers to ensure they are stored safely and won't pose a risk to workers or equipment. 4. Avoiding Tripping Hazards: Keep work areas clear of trip hazards, such as loose rebars or debris. Secure rebars in place to prevent them from rolling or shifting unexpectedly. 5. Cutting and Bending: When cutting or bending steel rebars, use appropriate tools and machinery designed for these tasks. Follow proper procedures and ensure that the work area is clear of other workers to prevent accidents or injuries. 6. Communication and Training: Clearly communicate and train all workers involved in handling steel rebars regarding the safety precautions and procedures to follow. This includes understanding the potential hazards, knowing how to use equipment properly, and being aware of emergency procedures. By following these safety precautions, the risk of accidents, injuries, and damage can be significantly reduced when handling steel rebars. It is important to prioritize safety in all aspects of the job to ensure the well-being of workers and the successful completion of the project.

- Q: Can steel rebars be used in railway and transportation infrastructure?

- Yes, steel rebars can be used in railway and transportation infrastructure. Steel rebars, also known as reinforcing bars, are commonly used in the construction industry to provide strength and support to concrete structures. In railway and transportation infrastructure, where robust and durable structures are required, steel rebars are often used to reinforce concrete elements such as bridge piers, abutments, and retaining walls. The use of steel rebars in railway and transportation infrastructure offers several advantages. Firstly, steel rebars enhance the tensile strength of concrete, making the structures more resistant to the dynamic and heavy loads imposed by trains and vehicles. This is particularly important in bridges and elevated structures where the loads can be significant. Secondly, steel rebars provide structural integrity and prevent the development of cracks and deformations in the concrete. This is crucial for maintaining the long-term stability and safety of the infrastructure, especially considering the constant exposure to various environmental conditions, such as temperature variations and vibrations. Furthermore, steel rebars are highly durable and resistant to corrosion, which is essential in railway and transportation infrastructure that is often exposed to harsh weather conditions and chemical agents. Their ability to withstand these factors ensures the longevity of the structures and reduces the need for frequent repairs and maintenance. In conclusion, steel rebars can and are commonly used in railway and transportation infrastructure due to their ability to enhance the strength, durability, and stability of concrete structures. Their use ensures the safe and reliable operation of these vital transportation systems, providing a solid foundation for the efficient movement of people and goods.

- Q: Are there any restrictions on the use of steel rebars in certain regions?

- Certain regions have restrictions on the use of steel rebars. These restrictions can differ from one region to another and are implemented to guarantee the safety and stability of structures. In specific locations, building codes and regulations may dictate particular criteria for the use of steel rebars, including their type, size, and placement. Additionally, there may be limitations on the utilization of certain types of steel rebars, such as epoxy-coated rebars, owing to environmental considerations. Construction professionals should acquaint themselves with the local building codes and regulations to ensure adherence and enhance the safety and longevity of structures.

- Q: What are the guidelines for protecting steel rebars in structures exposed to aggressive chemicals?

- The guidelines for protecting steel rebars in structures exposed to aggressive chemicals typically include using corrosion-resistant materials such as epoxy-coated rebars or stainless steel rebars, applying protective coatings on the rebars, ensuring proper concrete cover thickness, and implementing regular inspections and maintenance to identify and address any signs of corrosion.

- Q: How are steel rebars tested for quality and compliance?

- Steel rebars are tested for quality and compliance through a series of rigorous methods. These include visual inspection to check for any physical defects, such as surface imperfections or cracks. Additionally, rebars undergo chemical analysis to ensure they meet the required composition and strength specifications. Mechanical testing is conducted to assess the rebars' tensile strength, yield strength, and elongation properties. Another crucial test is the bend test, which evaluates rebars' ability to withstand bending without breaking or cracking. Overall, these various tests help ensure that steel rebars meet the necessary quality and compliance standards for their intended applications.

- Q: How are steel rebars protected from concrete spalling?

- Various methods and techniques are utilized to safeguard steel rebars from concrete spalling. One commonly employed approach involves the application of a concrete cover over the rebars. This entails embedding the rebars within the concrete structure to prevent direct exposure to external elements or conditions that may lead to spalling. To ensure adequate protection, construction codes and standards typically prescribe the thickness of the concrete cover. Another means of shielding steel rebars from concrete spalling is the use of corrosion inhibitors. These inhibitors are typically incorporated into the concrete mix during construction. They function by reducing the rate of corrosion for the steel rebars, effectively safeguarding them against spalling caused by rusting and corrosion. In addition to concrete cover and corrosion inhibitors, proper concrete mix design holds significant importance in protecting steel rebars. The utilization of high-quality concrete with an appropriate water-cement ratio, adequate strength, and suitable curing greatly enhances the concrete's resistance against spalling. This guarantees the secure embedding of the rebars within the concrete structure and shields them from moisture or other deteriorating agents that could lead to spalling. Furthermore, adhering to proper construction practices, such as thorough compaction of concrete, precise placement and alignment of rebars, and effective waterproofing measures, also contribute to the protection of steel rebars from concrete spalling. These practices help minimize the likelihood of moisture ingress and the formation of cracks or voids that could expose the rebars to the risk of spalling. In summary, a combination of concrete cover, corrosion inhibitors, appropriate concrete mix design, and sound construction practices are vital in safeguarding steel rebars from concrete spalling. By implementing these measures, the durability and lifespan of concrete structures can be significantly enhanced.

- Q: How do steel rebars contribute to the durability of concrete?

- Steel rebars contribute to the durability of concrete by providing reinforcement and strength to the structure. When embedded in concrete, rebars help to counteract tensile forces, which are the forces that tend to pull apart the concrete. This prevents cracking and enhances the structural integrity of concrete, making it more resistant to various external factors such as heavy loads, seismic activity, and temperature changes. Additionally, rebars help to distribute stress evenly throughout the concrete, reducing the risk of localized damage and increasing the overall longevity of the structure.

- Q: How do steel rebars affect the overall fire resistance of a structure?

- Steel rebars can significantly impact the fire resistance of a structure by providing reinforcement and preventing structural failure during a fire. Due to their high melting point, rebars can maintain the integrity of the concrete even when exposed to high temperatures. This helps to delay the onset of structural collapse, providing additional time for occupants to evacuate and firefighters to control the fire. Additionally, rebars can also enhance the load-bearing capacity of the structure, contributing to its overall fire resistance.

- Q: How do steel rebars contribute to the overall energy efficiency of a structure?

- Steel rebars contribute to the overall energy efficiency of a structure by enhancing its durability and strength. By reinforcing the concrete, they help to prevent cracks and ensure structural integrity, reducing the need for repairs and maintenance over time. This longevity reduces the energy consumption associated with frequent repairs and replacements, ultimately making the structure more energy-efficient.

Send your message to us

Steel Rebar/Deformed Steel Bar / Iron Rods for Construction/Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords