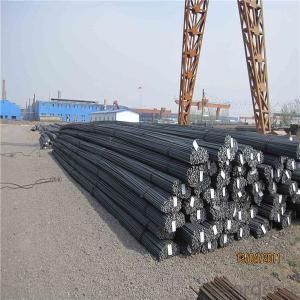

Deformed Steel Bar Iron Bars for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Deformed Steel Bar Iron Bars for Construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Deformed Steel Bar Iron Bars for Construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Deformed Steel Bar Iron Bars for Construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

iron bars for construction

Diameter 10-40mm

Grade: ASTM A615 Gr60; BS4999 Gr500

Size: 10#-40#

Length: 6M-12M

| Name | Deformed bar, steel rebar |

| Place of origin | China (mainland) |

| Material | HRB335, HRB400, HRB500, BS4449:2008 GR.460B / GR.500B ASTM A615 GR.40 / GR.60 |

| Standard | ASTM, BS, GB |

| Diameter | 8mm-50mm |

| Length | 9m,12m |

| Application | Widely used in construction industry for reinforcing concret |

| Trasportation | By sea(20' 40' container, BULK VESSEL), By rail |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What is the role of steel rebars in reducing concrete creep?

- Steel rebars play a crucial role in reducing concrete creep. Concrete creep refers to the gradual deformation or movement of concrete over time under sustained loading. This phenomenon occurs due to the long-term effects of stress and environmental factors on the concrete structure. By incorporating steel rebars into concrete structures, the creep behavior of concrete is significantly reduced. Steel rebars are high-strength reinforcement bars that are embedded within the concrete to enhance its structural integrity and durability. They provide tensile strength to counteract the tensile stresses that can cause concrete to creep. When concrete is subjected to sustained loads, such as the weight of a building or a bridge, it experiences internal stresses that can lead to creep. However, the presence of steel rebars helps to distribute these stresses more evenly throughout the structure. The rebars act as a reinforcement, absorbing and redistributing the tensile forces, thus minimizing the deformation of the concrete. Additionally, steel rebars also improve the bond between concrete and the reinforcement. This bond is essential for transferring the tensile forces from the concrete to the rebars and ensuring that they work together as a composite material. The strong bond between concrete and rebars prevents the formation of cracks, which can further contribute to creep. Furthermore, steel rebars also enhance the overall stiffness and rigidity of the concrete structure. This increased stiffness helps to resist the deformation caused by creep, maintaining the integrity and stability of the structure over time. In summary, the role of steel rebars in reducing concrete creep is vital. They provide tensile strength, distribute internal stresses, improve the bond between concrete and reinforcement, and enhance the overall stiffness of the structure. By incorporating steel rebars, engineers can effectively mitigate the effects of creep and ensure the long-term performance and durability of concrete structures.

- Q: How do steel rebars affect the thermal conductivity of a structure?

- Steel rebars can significantly affect the thermal conductivity of a structure. The thermal conductivity of steel is much higher than that of other construction materials such as concrete. When steel rebars are embedded within concrete structures, they create a path for heat to flow more easily through the structure. This increased thermal conductivity can have both positive and negative effects. On the positive side, the presence of steel rebars allows for efficient transfer of heat, which can be beneficial in certain applications. For example, in structures that require heating or cooling, such as buildings with HVAC systems, the steel rebars can assist in distributing the desired temperature more evenly throughout the structure. However, the increased thermal conductivity can also have negative consequences. In buildings where thermal insulation is crucial, such as those in extreme climates, the presence of steel rebars can lead to higher heat loss or gain. This can result in increased energy consumption and higher heating or cooling costs. To mitigate these negative effects, various insulation techniques can be applied to reduce the heat transfer through the steel rebars. One common practice is to add insulation layers around the rebars or to use materials with lower thermal conductivity for the concrete mix. These measures help to minimize the impact of the steel rebars on the overall thermal conductivity of the structure. In summary, steel rebars have a significant influence on the thermal conductivity of a structure. While they can enhance heat distribution in some cases, they can also contribute to increased energy consumption and heat loss. Proper insulation techniques should be implemented to minimize these negative effects and optimize the thermal performance of the structure.

- Q: What are the weight and density of steel rebars?

- The weight and density of steel rebars can vary depending on the specific composition and size of the rebar. On average, a typical steel rebar has a density of around 7850 kilograms per cubic meter and weighs approximately 7.85 kilograms per meter.

- Q: What are the common problems associated with steel rebars in construction?

- Some common problems associated with steel rebars in construction include corrosion, improper placement or spacing, inadequate cover, poor welding or splicing, and lack of proper anchorage.

- Q: How is steel rebar made?

- Steel rebar, short for reinforcing bar, is made through a process known as steel reinforcement fabrication. The first step in making steel rebar is to melt down raw materials such as iron ore, coal, and limestone in a blast furnace. This process, known as smelting, produces molten iron. Next, the molten iron is refined and purified in a basic oxygen furnace, where impurities such as carbon, sulfur, and phosphorous are removed. This refining process ensures that the resulting steel has the desired strength and properties. After refining, the steel is then cast into billets, which are long, solid bars. These billets are then heated and rolled into thin, elongated strands known as rebars. The rolling process involves passing the billets through a series of rollers that gradually shape and elongate the steel. Once the rebars are formed, they are cooled and cut into desired lengths. These lengths can vary depending on the intended use of the rebar, such as reinforcing concrete in buildings, bridges, or other structures. To further enhance the strength and durability of the rebar, it can undergo a process called quenching and tempering. This involves heating the rebar to a high temperature and then rapidly cooling it, followed by reheating and slow cooling. This process helps to improve the rebar's mechanical properties, making it more resistant to wear, corrosion, and other external forces. Finally, the rebar goes through a surface treatment process, such as hot-dip galvanizing or epoxy coating, to protect it from rust and corrosion. This coating ensures that the rebar maintains its structural integrity and longevity when used in various construction applications. Overall, the production of steel rebar involves a series of steps including smelting, refining, casting, rolling, cutting, heat treatment, and surface coating. These processes ensure that the final product meets the necessary strength and durability requirements for reinforcing concrete structures.

- Q: What is the process of straightening steel rebars?

- To ensure proper alignment and eliminate any bends or deformities, steel rebars must undergo a series of steps during the straightening process. To begin with, a thorough examination is conducted to identify any visible defects like twists, kinks, or bends. This initial assessment is crucial in determining the extent of straightening required and whether any rebars need replacement. Once the inspection is finalized, the rebars are loaded onto a straightening machine. This machine features rotating rollers or hydraulic pressure devices that exert force on the rebars to realign them. The rebars are fed through the rollers or placed amidst the hydraulic devices, and gradual pressure is applied to reshape the bars and eliminate any bends or twists. During the straightening procedure, it is of utmost importance to maintain control over the applied force to avoid excessive straightening or further damage to the rebars. Skilled operators supervise the machine and adjust the pressure accordingly to ensure precise straightening. Following the straightening process, a final inspection is conducted to confirm that the rebars meet the required specifications. This inspection consists of checking for any remaining deformities, ensuring the rebars are of the correct length, and verifying that they are straight within acceptable tolerances. It is worth noting that the straightening process may vary depending on the type and size of the rebars. For larger or more complex rebars, different machines and techniques may be employed. Additionally, the process may involve preheating the rebars to enhance their malleability before straightening. All in all, the process of straightening steel rebars involves meticulous inspection, the utilization of specialized machinery, skilled operators, and a final inspection to ensure the rebars are straight, aligned, and ready for use in diverse construction projects.

- Q: What are the guidelines for storing steel rebars on a construction site?

- The guidelines for storing steel rebars on a construction site typically include keeping them off the ground to prevent rust and corrosion, stacking them neatly and securely to avoid accidents, and protecting them from exposure to moisture and other harmful elements. It is also important to separate different sizes and types of rebars to ensure easy identification and accessibility when needed.

- Q: What are the common mistakes to avoid when handling and storing steel rebars?

- To ensure the quality and longevity of steel rebars, it is crucial to steer clear of certain common mistakes. Here are some errors that should be sidestepped: 1. Inadequate storage conditions: The storage of steel rebars in damp or wet areas can result in corrosion and rust. To prevent moisture accumulation, it is vital to store them in a dry and well-ventilated space. 2. Insufficient support: To prevent bending or deformation, it is important to provide proper support when stacking rebars. Insufficient support can damage the rebars and compromise their structural integrity. 3. Improper lifting techniques: It is essential to employ appropriate lifting equipment and techniques when handling rebars. Using hooks or chains directly on the rebars can weaken and damage them. It is advisable to use lifting devices specifically designed for rebar handling. 4. Overloading: Avoid placing excessive weight on storage racks or platforms. Overloading can cause structural failure and pose a risk to workers. Always adhere to the manufacturer's guidelines for maximum weight capacity. 5. Lack of protection: Rebars should be shielded from moisture, dirt, and other contaminants. Wrapping them properly with plastic or waterproof covers can prevent corrosion and maintain their quality. 6. Improper transportation: During transportation, take care to secure the rebars adequately to prevent movement or damage. Using appropriate restraints and padding can prevent potential accidents or rebar displacement. 7. Mixing different grades: Do not mix rebars of different grades together, as they possess varying strength and performance characteristics. Mixing different grades can compromise the overall structural integrity of the construction project. 8. Neglecting quality control: Conduct regular quality checks on the rebars to ensure they meet the required specifications. Neglecting quality control can result in the use of substandard rebars, jeopardizing the safety and durability of the structure. By avoiding these common mistakes, construction professionals can guarantee the proper handling and storage of steel rebars, leading to safer and more durable structures.

- Q: Can steel rebars be used in wind turbine foundation construction?

- Yes, steel rebars can be used in wind turbine foundation construction. Steel rebars are commonly used to reinforce concrete structures, including foundations, due to their high tensile strength and durability. They help enhance the structural integrity and stability of the foundation, making it suitable for supporting the weight and dynamic loads of wind turbines.

- Q: Cast-in-place with 10 mm reinforcement, a good layer or 8 mm double layer? Why?

- Double reinforcement should be adopted for roof bar reinforcement.(5) double deck two-way steel bars shall be installed in cast-in-place slabs with a thickness of more than 120mm.

Send your message to us

Deformed Steel Bar Iron Bars for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords