Steel Plate Lowest Price for Astm A36 carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Description of steel plate:

Our products into high-strength low-alloy steel plate, carbon structural steel plate, alloy structural steel plate, boiler and pressure vessel steel plate, bridge steel plate, structural steel plate, shipbuilding steel plate and marine oil platform steel plate, pipe steel plate, high strength and high toughness steel plate, mold plate, corrosion-resistant plate, Wear-resistand steel plate, composite plate with 12 major series.

2.Size range: Steel Plate width 300-5000mm, thickness 5-600mm, length 1000-18000mm.

Usage: (1).used for metallurgical, mechanical, electrical construction field

(2).used for ships, military (armored) Construction

(3).used for outside engineering, machine tool base, automobile rear of products

3.Standard: According to user requirements, can be delivered the following criteria: National standards, the metallurgical industry, the American ASTM, ASME standards, Japanese JIS, German DIN, British BS, European EN, the international ISO standards and the standards specific board.

4.Inspection Standard: In accordance with China (JB4730, GB/T2970), United States (A435, A577, A588), Japan (JISG0801, JISG0901), Germany (SEL072), British (BS5996), France (NFS04-305) and other domestic and international testing standard production test.

5.Data of steel sheet:

Chemical Requirements

| N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti | |

Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.30 | 0.35 | / | / | / | / | / | bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.50 | 0.40 | / | / | / | / | / | bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5-6.75 | 3.5-4.5 | / | / | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12-0.25 | / | / | bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | 0.2-4.0 | 0.6-0.9 | bal |

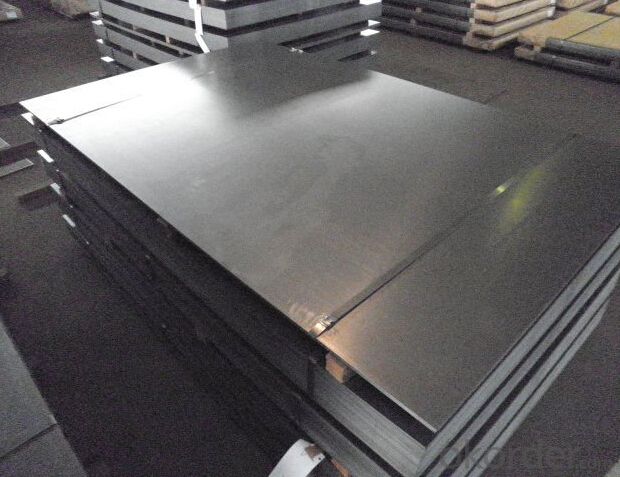

6.Image of steel sheet:

7.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the safety considerations when handling steel sheets?

- When handling steel sheets, there are several safety considerations to keep in mind. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. Secondly, steel sheets can be heavy and cumbersome, so it is crucial to use proper lifting techniques and equipment to avoid strains or muscle injuries. Additionally, sharp edges or corners on steel sheets can pose a risk of cuts or punctures, so caution should be exercised when handling them. Lastly, steel sheets can be slippery when wet or oily, so it is essential to maintain a clean and dry working area to prevent slips and falls. Overall, awareness, caution, and adherence to safety protocols are key when handling steel sheets to ensure the well-being of individuals involved.

- Q: What are the different surface treatments for steel sheets?

- There are several different surface treatments available for steel sheets, including galvanizing, powder coating, painting, and plating. These treatments help to protect the steel from corrosion, improve its appearance, and enhance its durability.

- Q: Can steel sheets be used for food processing applications?

- Yes, steel sheets can be used for food processing applications. Stainless steel sheets are commonly used in the food industry due to their corrosion resistance, durability, and ease of cleaning. They are suitable for various food processing equipment, such as conveyor belts, countertops, food storage containers, and cooking surfaces.

- Q: Can steel sheets be used in high-temperature applications?

- High-temperature applications can make use of steel sheets, as steel possesses exceptional heat resistance and can endure high temperatures while retaining its structural integrity. The suitability of steel for such applications is heavily influenced by its specific type and composition. Stainless steel or heat-resistant steel, for instance, are specifically engineered to withstand exceedingly high temperatures and are widely utilized in industries like aerospace, automotive, and manufacturing. These steel sheets are applicable in various high-temperature settings including furnaces, boilers, exhaust systems, and heat exchangers, among others. Nevertheless, it is crucial to consider factors such as the precise temperature range, duration of exposure, and the presence of any potentially corrosive elements in the high-temperature environment to ensure the selected steel sheet is suitable for the intended purpose.

- Q: Can steel sheets be used for solar panel mounting structures?

- Yes, steel sheets can be used for solar panel mounting structures. Steel is a commonly used material for solar panel mounts due to its strength, durability, and cost-effectiveness. It provides a sturdy framework to support the weight of the solar panels and withstand various weather conditions. Additionally, steel sheets can be easily fabricated and customized to meet specific project requirements, making them a suitable choice for solar panel mounting structures.

- Q: How do you calculate the yield strength of a steel sheet?

- To calculate the yield strength of a steel sheet, you need to conduct a test called a tensile test. This test involves stretching a sample of the steel sheet until it reaches its breaking point. During the test, you measure the stress and strain applied to the sample. The yield strength is the point at which the material begins to deform plastically, meaning it does not return to its original shape after the stress is removed. It is an important mechanical property as it indicates the maximum amount of stress a material can withstand without permanent deformation. During the tensile test, you measure the stress applied to the steel sheet as you increase the strain on the sample. Stress is calculated by dividing the force applied to the sample by its original cross-sectional area. Strain is determined by dividing the change in length of the sample by its original length. The yield strength is defined as the stress at which a specific amount of permanent deformation occurs, typically 0.2% strain or 0.2% offset. This means that the yield strength is the stress required to cause a 0.2% change in length of the sample. Once you have obtained the stress-strain data from the tensile test, you can plot a stress-strain curve. The yield strength is then determined by finding the point on the curve where the stress corresponding to the specified amount of strain is reached. In summary, to calculate the yield strength of a steel sheet, you need to perform a tensile test and measure the stress and strain applied to the sample. From the stress-strain curve, you can determine the point at which a specific amount of permanent deformation occurs, which is the yield strength of the steel sheet.

- Q: What is the difference between a pre-annealed and full hard steel sheet?

- A pre-annealed steel sheet is a sheet that has undergone an annealing process to relieve internal stresses and enhance its formability. It is softer and more malleable compared to a full hard steel sheet. On the other hand, a full hard steel sheet has not undergone any additional treatment after being cold-rolled, making it harder and less ductile. It is typically used for applications requiring higher strength and stiffness.

- Q: Can the steel sheets be easily painted or coated?

- Indeed, it is possible to effortlessly paint or coat steel sheets. The sleek texture of these sheets enables exceptional paint or coating adherence. Before proceeding with the painting or coating process, it becomes crucial to diligently cleanse the surface to eliminate any potential dirt, grease, or rust that may hinder proper adhesion. Additionally, the utilization of a primer or base coat can considerably augment the resilience and longevity of the applied paint or coating. In summary, steel sheets furnish a fitting and conveniently paintable surface for an array of purposes.

- Q: How do steel sheets perform in terms of dimensional stability?

- Steel sheets are known for their excellent dimensional stability. This means that they are highly resistant to changes in size or shape when subjected to external forces or fluctuations in temperature. Steel is inherently strong and rigid, allowing it to maintain its shape and dimensions over extended periods of time. Additionally, steel sheets have low thermal expansion coefficients, meaning they expand and contract minimally with changes in temperature. This characteristic further enhances their dimensional stability, making them suitable for applications where precise dimensions and consistent performance are critical. Steel sheets are widely used in various industries, including construction, automotive, and manufacturing, due to their reliable dimensional stability.

- Q: Can steel sheets be used for storage racks or shelving?

- Yes, steel sheets can be used for storage racks or shelving. Steel sheets are durable, strong, and resistant to damage, making them suitable for heavy-duty storage applications. Additionally, their versatility allows for customization and various configurations to meet specific storage needs.

Send your message to us

Steel Plate Lowest Price for Astm A36 carbon

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords