Steel H Beam for Building with Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cheap Price Steel H Beam for Building Details

Place of Origin: | China (Mainland) | Grade: | Q235 | Technique: | Hot Rolled |

Thickness: | 6-12mm | Application: | Steel Building Structure | Length: | 12m |

Standard: | JIS | Flange Width: | 50-400mm | Flange Thickness: | 7-28mm |

Web Width: | 50-400mm | Web Thickness: | 5-21mm | Brand Name: | AJ |

Model Number: | HB400 | Color: | Black | shape: | H |

Packaging & Delivery

Packaging Detail: | in bundle with steel wire |

Delivery Detail: | within 15 days after receipt of deposit |

Cheap Price Steel H Beam for Building Advantages

Steel H beam is more flexible in use and save more material than traditional I beam.

Steel H beams are widely used in the construction industry and are available in a variety of standard sizes.

H steel beam may be used both as beams and as columns.It may be used both on their own, or acting compositely with another material, typically concrete.

H shape steel beam has wider flanger than normal I beam,more stable to use.

The construction time of steel h beam will be twice or more faster than use concrete.

Cheap Price Steel H Beam for Building Specifications

Height*Width (mm) | Web thickness (mm) | Flange thickness (mm) | kg/m | Height*Width (mm) | Web thickness (mm) | Flange thickness (mm) | kg/m |

| 150*100 | 6 | 9 | 21.4 | 506*201 | 19 | 103.1 | |

| 200*150 | 6 | 9 | 31.2 | 600*200 | 10 | 15 | 95.2 |

| 250*175 | 7 | 11 | 44.1 | 11 | 17 | 106.1 | |

| 300*200 | 8 | 12 | 57.3 | 12 | 20 | 120.3 | |

| 350*250 | 9 | 14 | 79.7 | 700*300 | 13 | 20 | 166 |

| 400*300 | 10 | 16 | 107.3 | 13 | 24 | 185 | |

| 450*300 | 11 | 18 | 124 | 800*300 | 14 | 22 | 191 |

| 500*300 | 11 | 15 | 115 | 14 | 26 | 210 | |

| 11 | 18 | 129.1 | 900*300 | 16 | 28 | 243 |

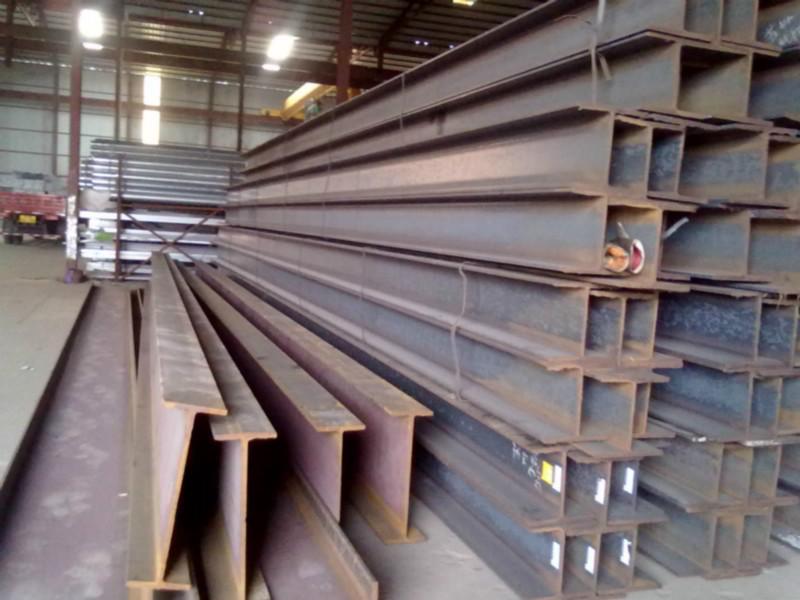

Cheap Price Steel H Beam for Building Pictures

- Q: How do steel H-beams perform in high-humidity environments?

- Steel H-beams are generally highly resistant to high-humidity environments. The steel used in H-beams is typically coated or galvanized, providing a protective layer that helps prevent corrosion. This coating acts as a barrier against moisture, reducing the chances of rust formation and degradation. In high-humidity environments, such as coastal areas or regions with high levels of moisture, steel H-beams are designed to withstand the conditions without significant deterioration. The protective coating on the beams ensures their longevity and structural integrity, even in the presence of moisture. However, it is important to note that prolonged exposure to high levels of humidity, along with other factors such as saltwater or chemicals, can still potentially lead to corrosion over time. Regular maintenance and inspection of the steel H-beams should be conducted to identify any signs of corrosion or damage and take appropriate measures to address them. Overall, steel H-beams are a reliable choice for structures in high-humidity environments due to their resistance to moisture and corrosion. Their robust construction and protective coating make them suitable for withstanding the challenges posed by such conditions, ensuring their long-term performance and durability.

- Q: How do steel H-beams perform in areas with high snow load?

- Steel H-beams are renowned for their exceptional strength and durability, making them a suitable choice for regions with heavy snow loads. The unique H-shaped profile of these beams offers enhanced structural stability, enabling them to effectively endure the weight and pressure exerted by substantial snow accumulation. One noteworthy advantage of steel H-beams in snowy areas lies in their remarkable load-bearing capacity. The design of the H-shape evenly distributes weight across the beam, reducing the risk of bending or deforming when subjected to intense snow loads. This guarantees that buildings or structures maintain their structural integrity, thereby mitigating potential hazards associated with heavy snowfall. Furthermore, steel H-beams exhibit excellent resistance to bending, twisting, and shearing forces. These properties make them highly reliable and capable of withstanding dynamic loads caused by snow loads, such as the force exerted by snow sliding off a roof or the impact of strong winds combined with snowfall. In addition, steel H-beams are renowned for their corrosion resistance, a crucial characteristic in regions with high snow loads. Snow often contains moisture that can infiltrate the structural elements of a building, potentially leading to rusting and material weakening. However, steel H-beams are typically coated with protective layers or galvanized to prevent corrosion, ensuring their long-term performance and structural integrity in harsh snowy environments. To summarize, steel H-beams are an excellent option for regions with heavy snow loads due to their exceptional strength, load-bearing capacity, resistance to deformation, and corrosion resistance. These beams provide a secure and durable structural support system, guaranteeing the safety and stability of buildings and structures amidst heavy snowfall conditions.

- Q: How do Steel H-Beams contribute to the overall daylighting or natural lighting of a structure?

- The main purpose of Steel H-Beams is to provide structural support and stability to a building, rather than directly contributing to its overall daylighting or natural lighting. These beams are commonly utilized in construction projects to bear heavy loads, such as the weight of floors, walls, and roofs. Daylighting or natural lighting in a building refers to the utilization of natural light to illuminate the interior spaces, reducing the need for artificial lighting during the daytime. To optimize the entry of natural light, various architectural elements and design strategies are employed, including the incorporation of large windows, skylights, light shelves, and light tubes. Although Steel H-Beams do not directly contribute to daylighting, they play an indirect role in supporting the architectural elements that facilitate natural lighting. By providing the necessary framework and structural integrity, these beams allow for the installation of large windows, skylights, and other elements that maximize the entry of natural light into the building. With their reliable support system, Steel H-Beams enable architects and engineers to design buildings with larger openings for windows and skylights, thereby allowing more natural light to penetrate the interior spaces. Therefore, while Steel H-Beams may not directly contribute to daylighting or natural lighting, they are crucial in creating a structural framework that supports the architectural elements responsible for maximizing the entry of natural light into a building.

- Q: What are the load-bearing capabilities of steel H-beams?

- Steel H-beams are commonly used in construction and structural engineering due to their high load-bearing capabilities. The load-bearing capabilities of steel H-beams depend on various factors such as the size and shape of the beam, the grade and quality of the steel used, the span and support conditions, and the type and magnitude of the load being applied. Steel H-beams are designed to withstand heavy loads and provide structural stability. They are capable of supporting significant vertical and horizontal loads, making them ideal for use in large-scale construction projects such as bridges, skyscrapers, and industrial buildings. The load-bearing capacity of steel H-beams can be further enhanced by using thicker or higher-grade steel, increasing the size or depth of the beam, or by adding additional support elements such as columns or braces. The load-bearing capabilities of steel H-beams are typically specified by engineers and designers based on the specific requirements of the project. Structural calculations and analysis are performed to determine the maximum load that the beam can safely carry without failure or excessive deflection. These calculations take into account factors such as the material properties of the steel, the design of the beam, the applied loads, and the safety factors required by building codes and regulations. In summary, steel H-beams possess excellent load-bearing capabilities and are widely used in construction and structural engineering. Their strength and durability make them suitable for supporting heavy loads and ensuring the structural integrity of various types of buildings and structures. However, it is important to consult with a structural engineer or professional to accurately determine the load-bearing capabilities of steel H-beams for a specific project.

- Q: Can steel H-beams be used in wastewater treatment plants?

- Indeed, steel H-beams find utility within wastewater treatment plants. Their commendable strength and durability render them appropriate for an array of structural functions in such facilities. These beams may be employed to uphold weighty machinery and equipment, erect platforms and walkways, as well as provide structural reinforcement for diverse treatment procedures. Furthermore, steel H-beams exhibit resistance to corrosion, a crucial characteristic within environments featuring elevated moisture content and chemical substances. By applying suitable coatings and conducting regular upkeep, steel H-beams ensure enduring and dependable support within wastewater treatment plants.

- Q: In actual steel structure engineering, why use H steel in large number, but seldom use I-beam? What's the difference between the two?

- I type is fixed, then the first, the "code" is not very full, for example: 32#c I-beam size is 320X134X13.5, then a large number is 36#a (360X136X10). The choice of small; second, his section height and width dimensions is that several, to meet the design conditions tend to produce waste, for example, sometimes Web condition is satisfied, the flange is not enough.

- Q: Can Steel H-Beams be used in bridge or infrastructure construction?

- Yes, steel H-beams can be used in bridge or infrastructure construction. Steel H-beams are widely used in the construction industry due to their strength, durability, and versatility. They have a high load-bearing capacity, making them suitable for supporting heavy loads in bridge structures. H-beams can be used as primary structural members in bridge girders, providing the necessary strength and stability for the bridge to withstand various loads, including the weight of vehicles and pedestrians. Additionally, H-beams are also commonly used in the construction of infrastructure such as buildings, highways, and railway tracks. Their adaptability allows for efficient construction and design flexibility, making steel H-beams a popular choice in bridge and infrastructure projects.

- Q: Can steel H-beams be used in multi-story buildings?

- Yes, steel H-beams can definitely be used in multi-story buildings. These beams are widely used in construction due to their high strength and structural integrity. They provide excellent support and stability, making them suitable for withstanding the loads and stresses associated with multi-story structures.

- Q: Can steel H-beams be used for pedestrian walkways?

- Indeed, pedestrian walkways can indeed utilize steel H-beams. Owing to their robustness and longevity, steel H-beams are frequently employed in construction projects. These beams offer a secure support structure capable of enduring substantial weights, thereby guaranteeing the safety of pedestrians. Moreover, steel H-beams can be tailored to meet specific criteria concerning dimensions, rendering them adaptable for diverse walkway designs. These beams are also impervious to adverse weather conditions and demand minimal maintenance, rendering them a perfect selection for pedestrian walkways, regardless of whether they are situated indoors or outdoors.

- Q: Are steel H-beams suitable for stadiums?

- Yes, steel H-beams are commonly used in stadium construction due to their strength, durability, and ability to support heavy loads. The H-beam design provides excellent structural support, making them suitable for stadiums where large spans and high load capacities are required.

Send your message to us

Steel H Beam for Building with Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords