Steel Frame Formwork GK120 with Favorable Prices for High-rise Buildings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

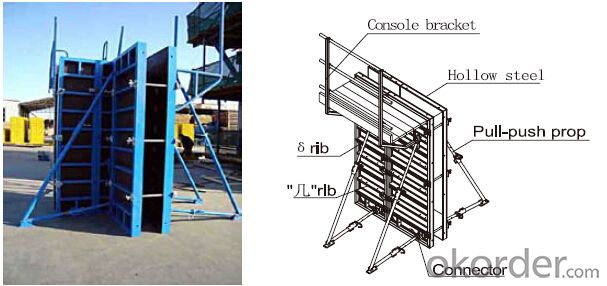

1. Structure of Steel Frame Formwork GK120

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Steel Frame Formwork GK120

- High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the Timber Beam Wall Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

- Q: I got my industrial pierced on august 17th of this year. About 2 weeks ago this little bump formed on the outside of the bottom hole...i was wondering if i took it out to get it cleaned really good since its kinda hard to fully clean it would that affect it in any negative way? Its only been a month so im a little apprehensive about taking it out but it would only be for a couple minutes...please help!!!!!!!!!!

- It is probably just scar tissue. I would leave the piercing alone or contact the person who did the piercing.

- Q: A 105 kg scaffold is 6.2 m long. It is hanging with two wires, one from each end. A 520 kg box sits 2.2 m from the left end. What is the tension in the right hand side wire?(g = 9.8 m/s2)

- assuming the 105 kg scaffold is uniform taking moment abt left end T * 6.2 = 105 *g * 3.1 + 520 g *2.2 T = 2322.76N answer tension in the right hand side wire

- Q: PLEASE HELP!!!

- A brick is dropped from a high scaffold. What is its velocity after 2.9 s? As an object fall, neglecting air resistance, its velocity increases 9.8 m/s each second. Final velocity = Initial velocity + 9.8 * time Initial velocity = 0 m/s Final velocity = 0 + 9.8 * 2.9 Final velocity = 28.42 m/s

- Q: The amount of bowl buckle scaffolding, know the area of 50000m2, height 6m, how to calculate the number of posts with the root, the number of bowl buckle on the number of how many?

- Unable to determine pitch and step reference 0.6m and 1.0m

- Q: I'm 16 and I already have 3 piercings in each lobe, one on one ear stretched to 12mm. I didn't really think they hurt that much. I also have my nose pierced and had that done with a needle (thus hurting more than a gun) and I mean that hurt but I didn't cry or anything or start freaking out. If I do get my scaffold piercing I'll be going to a very good and trusted piercing and tattoo shop, where the person piercing me will probably be someone I know, so I completely trust them. I am pretty good with pain I supposeI just want some idea of how much it will hurtThankyou (:

- Yes. It like someone pinching you for a short period of time

- Q: Hi my next door neighbours are building an extension to their house. The builders asked if we would allow scaffolding to be placed on part of our driveway. Now, these builders are taking too long and the builders attitude is rude when questioned how long they gonna take to finnish. If we want the scaffolding to go, what righs have we got as we gave verbal permission to the builders to have it put up by scaffolders and the planned extension not yet completed?

- mom says more rights than the neighbor since they are taking too long to finish its in your favor - it is your property not the contractors mom would make a comment like this to that rude contractor since you have left this scaffolding abandoned in my drive way for a month (whatever time) i am sure that when you return in the morning someone else will have removed it for me since your permission time has long expired and you have been repeatedly asked to remove it - so if you value your equipment investment it will be gone before supper tonight - AM I UNDERSTOOD !!! (that last part would be really loud and right in his face, probably with a finger poke in the chest) then when they don't remove it be prepared with wrenches and a pick up truck to remove it before their return in the morning - stashing it out of sight but on the property when they question you about the missing scaffolding you can offer to rent one to them that was abandoned in your driveway for $500.00 dollars a day (she would smile her prettiest smile when she said this) be prepared for a fuss - but they had their chance - stand your ground that's how mom rolls - she plays for keeps - not many cross her - when they do they quickly regret it - she would have it in small pieces in front of their eyes, but she suggests the first description for you - mom is tough but incredibly fair - the rules are the rules for a reason whether you like it or not, or anybody else for that matter

- Q: is it possible to have an industrial piercing done in 2 stages? so like 1 hole first and then a few weeks later the 2nd hole done. ive found a place that for 2 holes is cheaper than having the whole process done as one. Please help :)

- yes it is possible. I know people who have done that. But I suggest getting it done at once because it will hurt less in the long run. Getting your cartilage done hurts for about 2 weeks and then get the top part done that is another 2 weeks. So to get it done together it will only hurt for 2 weeks in instead of 4.

- Q: I can't use metal because my ear swells up, so does anyone know where I can get a barbell made of silver?Thanks :).

- Silver also contains nickel ( which causes allergies) and other nasty metals. Sterling silver - with the well known 924 stamp - contains 92.5% real silver and 7.5% of other metals, nickel included. Also silver turns black after a while and this black thing especially on a kinda new piercing can easily cause permanent discoloration of the skin ( black/green spot on the piercing hole ) That is why at all piercing studios they only use : Titanium, stainless steel, 18K and above gold. Titanium is the best metal by far. No allergies, no skin sensitivity and body loves it. It's also not expensive at all. It has a beautiful silver color which stays shiny for ever. You can find those jewelry online and on other places as well but it's best to get body jewelry from Tattoo/Piercing parlors. There are a lot of titanium and stainless steel jewelry around which are not great in quality. They are polished ( real titanium is not polished and the color is original done with a very special method ) and they are not than fine. So if you don't have a shop that you trust it's better to go to a professional piercing studio ( not at Claire's and places like that ) to get it.

- Q: stands there.?(from the scarlet letter book.)

- I would describe her as strong. The woman has convictions, and she's not ashamed of what she's done. Instead of giving in and telling everybody who the father is so she can lessen her sentence, she stands firm in her actions.

- Q: I want this piercing in my ear called Scaffolding, it looks like this

- I think it depends on your threshold of pain, but my friend had it and she's a pretty big wimp and she said that it hurt, but wasn't unbearable. Plus she gets tons of complements on it now!

Send your message to us

Steel Frame Formwork GK120 with Favorable Prices for High-rise Buildings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords