Steel Flat Bar 42CrMo, 4140, 40Cr Alloy

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Flat Bar 42CrMo, 4140, 40Cr Alloy at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Flat Bar 42CrMo, 4140, 40Cr Alloy are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar 42CrMo, 4140, 40Cr Alloy are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1) Specification: 10-120mm * 200-800mm, or as per customer's requirement

2) Delivery condition: EAF+LF+VD, Hot rolled, annealed, black surface, UT tested

| ASTM | USA | Ameirican Society of Mechanical Engineers |

| AISI | USA | Acronym of American Iron and Steel Institute |

| JIS | JP | Japanese Industrial Standards |

| DIN | GER | Deutsches Institut für Normung e.V. |

| UNS | USA | Unified Numbering System |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

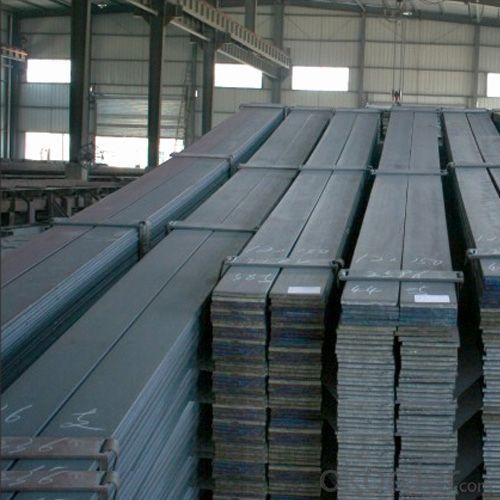

Images:

- Q: Can steel flat bars be used in the construction of buildings?

- Indeed, buildings can be constructed using steel flat bars. Owing to their robustness, endurance, and adaptability, steel flat bars are frequently employed in construction. They offer structural reinforcement and are commonly utilized for framing, reinforcement, and support systems within buildings. Steel flat bars can be conveniently fashioned, welded, and molded to fulfill the precise demands of a construction endeavor. Furthermore, they possess resistance against corrosion, fire, and pests, rendering them an excellent option for constructing enduring and robust buildings.

- Q: Can steel flat bars be used in the manufacturing of automotive parts?

- Yes, steel flat bars can be used in the manufacturing of automotive parts. Steel flat bars offer high strength and durability, making them suitable for various automotive applications such as chassis components, brackets, supports, and structural reinforcements. Their versatility, cost-effectiveness, and ability to be easily fabricated and welded make them a popular choice in the automotive industry.

- Q: What is the standard thickness of a steel flat bar?

- The standard thickness of a steel flat bar can vary depending on the specific application and industry standards. However, commonly available steel flat bars typically range in thickness from 1/8 inch to 1 inch. It is important to note that custom sizes and thicknesses are also available to meet specific requirements.

- Q: How are steel flat bars used in the manufacturing of machinery?

- Due to their versatility and strength, steel flat bars are commonly employed in machinery manufacturing. These bars, which can be made from different grades of steel like carbon steel or stainless steel, offer exceptional durability and resistance to corrosion. One of the primary applications of steel flat bars in machinery manufacturing is providing structural support. These bars can serve as a base or framework for various machine components, offering a stable and robust foundation. They are frequently joined together through welding or bolting to create a sturdy structure capable of withstanding heavy loads and vibrations. Moreover, steel flat bars are utilized in constructing machine parts. They can be cut, shaped, and machined into different forms, such as brackets, plates, or supports, to fulfill specific functions within the machinery. These parts may serve as mounting points for other components, reinforcement, or guides for moving parts. Additionally, steel flat bars are often employed in fabricating cutting tools and blades. Their hardness and toughness make them suitable for applications that demand sharp edges and resistance to wear. These bars can be shaped and sharpened into blades for cutting, shearing, or chopping processes, thus enhancing the machinery's efficiency and precision. Apart from their mechanical properties, steel flat bars are also valued for their cost-effectiveness. Steel is a widely available material, making it an economical choice for machinery manufacturers. Furthermore, its recyclability and long lifespan contribute to its sustainability, aligning with the increasing demand for environmentally friendly manufacturing practices. Overall, steel flat bars play a vital role in machinery manufacturing, offering structural support, forming machine parts, and functioning as cutting tools. Their versatility, strength, and cost-effectiveness make them a preferred choice for engineers and manufacturers in diverse industries.

- Q: What is the difference between a steel flat bar and a steel hex bar?

- The main difference between a steel flat bar and a steel hex bar lies in their shape. A steel flat bar has a rectangular cross-section with flat and smooth surfaces, while a steel hex bar has a hexagonal cross-section with six flat and smooth surfaces. This difference in shape makes them suitable for different applications and provides options for various construction and manufacturing purposes.

- Q: Can steel flat bars be used for manufacturing storage racks or shelves?

- Steel flat bars are suitable for the manufacturing of storage racks or shelves. They are extensively utilized in the construction sector owing to their robustness and resilience. These bars offer a solid foundation for storage racks or shelves and can withstand heavy loads without any deformation or distortion. Furthermore, it is effortless to weld or bolt steel flat bars together, enabling the creation of customized storage solutions tailored to specific needs. Consequently, opting for steel flat bars is an outstanding decision when it comes to manufacturing storage racks or shelves.

- Q: How do steel flat bars contribute to the overall sustainability of residential projects?

- Steel flat bars contribute to the overall sustainability of residential projects in several ways. Firstly, steel is an incredibly durable and long-lasting material. Steel flat bars are resistant to corrosion, weathering, and pests, meaning they require minimal maintenance over their lifespan. This durability ensures that residential structures built with steel flat bars have a longer lifespan, reducing the need for frequent repairs and replacements, thereby reducing waste and conserving resources. Additionally, steel is one of the most recycled materials in the world. Steel flat bars can be easily recycled at the end of their life, reducing the demand for new steel production and the associated environmental impacts. This recycling process requires less energy and emits fewer greenhouse gases compared to the production of virgin steel. By incorporating steel flat bars into residential projects, we contribute to the circular economy by promoting the reuse and recycling of materials. Furthermore, steel flat bars offer strength and versatility in construction. Their high strength-to-weight ratio allows for lighter structural elements, reducing the overall weight of the building and the amount of material needed. This not only minimizes the environmental impact during the construction phase but also reduces the load on the foundation, resulting in potential energy savings over the building's lifespan. Steel flat bars also contribute to the sustainability of residential projects by providing design flexibility. Their availability in various sizes, shapes, and finishes allows architects and engineers to create innovative and efficient designs. This flexibility enables the optimization of material usage, minimizing waste and maximizing resource efficiency. Lastly, steel flat bars are fire-resistant, making them a safe choice for residential construction. This fire resistance can enhance the overall safety of the building and reduce the risk of fire-related damage or loss, ultimately minimizing the environmental impact associated with rebuilding or repair. Overall, the use of steel flat bars in residential projects promotes sustainability by providing durability, recyclability, strength, design flexibility, and fire resistance. Incorporating these sustainable features into residential construction helps reduce waste, conserve resources, and minimize the environmental footprint of the built environment.

- Q: Are steel flat bars suitable for high-temperature environments?

- Steel flat bars are generally suitable for high-temperature environments, but the specific type of steel used and the maximum temperature it can withstand will depend on the application. Stainless steel flat bars, for example, are known for their excellent heat resistance and can be used in temperatures up to 1500°F (816°C). They exhibit good mechanical properties and can maintain their strength and shape even at high temperatures. However, it is important to consider the specific requirements of the high-temperature environment. Some factors to consider include the length of exposure to high temperatures, the presence of corrosive substances, and the potential for thermal expansion or contraction. In extreme cases, such as in furnace applications, specialized high-temperature alloys or refractory metals may be more suitable. It is always recommended to consult with a materials engineer or specialist to determine the best steel flat bar for a specific high-temperature application. They can assess the requirements and provide guidance on the appropriate steel grade, heat treatment, and any additional protective measures that may be necessary to ensure optimal performance in such environments.

- Q: Can steel flat bars be welded or joined together?

- Steel flat bars can indeed be welded or joined together. The process of welding is widely employed to join metal components, including steel flat bars. During welding, the edges of the steel bars are melted and fused together using a welding filler material. This results in a robust and long-lasting bond between the flat bars. However, it is crucial to verify that the steel flat bars being welded possess the same or similar composition to avoid any complications with the quality of the weld. Moreover, employing appropriate welding techniques and equipment is essential to attain a weld of superior quality and guarantee the structural soundness of the joined steel flat bars.

- Q: Can steel flat bars be used for making furniture?

- Yes, steel flat bars can be used for making furniture. Steel is a versatile and durable material that can be shaped and welded into various furniture designs. Steel flat bars are commonly used to construct furniture pieces such as tables, chairs, shelves, and bed frames. They provide stability, strength, and a modern aesthetic to furniture designs. Additionally, steel can be coated or finished with different colors and textures to match different interior styles. However, it is important to consider the weight and potential sharp edges of steel flat bars when designing and using furniture made from this material.

Send your message to us

Steel Flat Bar 42CrMo, 4140, 40Cr Alloy

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords