Melt Extract Stainless Steel Fiber Reinforced Construction and Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland), Shandong, China (Mainland)

Model Number: GLUED, glued steel fiber

Material: Steel

type: steel fiber for concrete reinforcement

material: steel wire

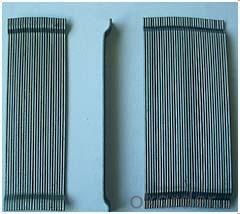

shape: glued together in a row

appearance: clear and bright

Product features

glued steel fiber together in a row ,is used with cement for construction

oncrete steel fiber is specifically to enhance concrete in its hardened state ,the uniform distribution of steel fiber throughout the concrete greatly improve concrete bonding and tensile strength ,additionally it provides exceptional load stability and durability ,as reliable and efficient concrete reinforcement material

it is widely ued in buildings ,bridges ,thin roo engineering ,highway etc.

Specifications

length :20-60mm

diameter :0.5MM-1.2MM

tensile strengh:>1100Mpa

| diameter | length | tensile strength | |

| 0.5mm | 35mm | 1100Mpa | |

| 0.75 | 60mm | 1100Mpa | |

| 0.9 | 60m | 1100Mpa |

Picture

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

- Q: Can melt extract stainless steel fiber be used in precast concrete wall panels?

- Precast concrete wall panels can utilize melt extract stainless steel fiber, which enhances the material's mechanical properties by improving its tensile strength, toughness, and durability. The inclusion of stainless steel fibers in precast concrete wall panels provides additional reinforcement and reduces the risk of cracking and shrinkage. These fibers distribute stresses more evenly throughout the concrete, resulting in improved structural performance. Melt extract stainless steel fibers are well-suited for precast concrete applications due to their high melting point and corrosion resistance. This makes them highly durable and capable of withstanding harsh environmental conditions, including freeze-thaw cycles, chemicals, and moisture. Furthermore, melt extract stainless steel fibers are available in various lengths, diameters, and aspect ratios, allowing for customization based on the specific requirements of the precast concrete wall panels. This flexibility in fiber selection ensures that the desired mechanical properties of the concrete can be achieved. In conclusion, melt extract stainless steel fiber is an appropriate choice for reinforcing precast concrete wall panels, as it enhances their strength, durability, and performance.

- Q: Can melt extract stainless steel fiber be used in precast tunnel portals?

- Precast tunnel portals can benefit from the utilization of melt extract stainless steel fiber. This material, renowned for its exceptional durability and resistance to corrosion, is widely employed in construction projects, specifically those involving tunnels. The incorporation of stainless steel fiber in tunnel portals serves to bolster the overall sturdiness and longevity of the precast concrete panels. By reinforcing the concrete, it fortifies its ability to withstand cracks and spalling, which is especially crucial due to the substantial stress and impact experienced by tunnel portals. Moreover, stainless steel fiber also enhances the fire resistance of precast panels. It effectively safeguards the concrete against spalling and disintegration when subjected to high temperatures, thus enhancing the structural integrity of the tunnel portal in the event of a fire. Additionally, melt extract stainless steel fiber exhibits remarkable resistance to corrosion, rendering it suitable for use in tunnel portals exposed to harsh environmental conditions, such as moisture and chemicals. It contributes to extending the lifespan of precast panels while minimizing the necessity for frequent maintenance or repairs. In summary, melt extract stainless steel fiber proves to be an effective solution for enhancing the strength, durability, fire resistance, and corrosion resistance of precast tunnel portals. Its integration into the construction process leads to the creation of tunnel portals that are longer-lasting and more dependable.

- Q: Does melt extract stainless steel fiber improve the resistance to impact of shotcrete?

- Indeed, the incorporation of melt extract stainless steel fiber in shotcrete does indeed enhance its resistance to impact. Shotcrete, a technique involving the high-velocity spraying of concrete onto a surface, benefits from the inclusion of stainless steel fiber, which serves to fortify its impact resistance. Acting as reinforcement within the shotcrete, these stainless steel fibers bolster its durability and capacity to withstand forces of impact. By absorbing and dispersing the energy arising from impacts, these fibers decrease the likelihood of cracks, spalling, and other forms of damage. Moreover, the stainless steel fibers augment the shotcrete's tensile strength, rendering it more resistant to cracking and elevating its overall structural integrity. Undoubtedly, the addition of melt extract stainless steel fiber to shotcrete yields a significant enhancement in its resistance to impact, establishing it as the preferred choice for applications where impact resistance is paramount, such as tunnels, bridge decks, and retaining walls.

- Q: C50 steel fiber concrete, the minimum price, who will tell

- This has to know the amount of steel fiber and kind of Caixing, different steel fiber price difference is quite big, mixing quantity is different, the cost difference is also very big.

- Q: How does melt extract stainless steel fiber affect the shrinkage and creep of concrete?

- Melt extract stainless steel fiber is commonly used as a reinforcement material in concrete to improve its overall strength and durability. When added to concrete, these fibers provide additional tensile strength and reduce the potential for cracking. In terms of shrinkage, melt extract stainless steel fibers can help minimize the shrinkage of concrete. Shrinkage occurs as water evaporates from the concrete during the curing process, leading to volume reduction. The addition of stainless steel fibers helps to distribute the internal stresses and restrain the shrinkage. This results in reduced shrinkage cracks and an overall decrease in the amount of shrinkage experienced by the concrete. Similarly, when it comes to creep, which is the time-dependent deformation of concrete under sustained load, melt extract stainless steel fibers play a crucial role. Creep occurs due to the ongoing chemical and physical processes within the concrete, causing it to gradually deform over time. The presence of stainless steel fibers in the concrete helps to control this creep deformation by providing additional resistance against the applied load. The fibers act as a reinforcement, distributing the stresses and reducing the overall creep strain in the concrete. In summary, the addition of melt extract stainless steel fiber to concrete significantly affects the shrinkage and creep properties. It helps to minimize shrinkage by distributing internal stresses and restraining volume reduction. Additionally, it controls creep deformation by providing additional resistance against sustained loads and reducing the overall creep strain. Overall, the presence of stainless steel fibers improves the long-term performance and durability of concrete structures.

- Q: How does melt extract stainless steel fiber affect the rheology of self-compacting concrete?

- The rheology of self-compacting concrete is greatly influenced by the inclusion of melt extract stainless steel fibers. Rheology pertains to the flow characteristics and behavior of a substance, and in the case of self-compacting concrete, it determines its ability to flow and fill intricate forms without mechanical consolidation. The addition of melt extract stainless steel fibers to self-compacting concrete serves as reinforcement, enhancing its mechanical properties. These fibers enhance the structural integrity of the concrete matrix by imparting tensile strength, crack resistance, and improved ductility. This reinforcement effect leads to improved rheological properties of self-compacting concrete. Reducing segregation and bleeding is one of the primary impacts of melt extract stainless steel fibers on the rheology of self-compacting concrete. The fibers aid in the uniform distribution of aggregates, preventing their settlement and resulting in a more homogeneous mixture. This reduces the risk of particle segregation during pouring and casting, resulting in improved flowability and stability of the concrete. In addition, the presence of stainless steel fibers improves the viscosity and yield stress of self-compacting concrete. The fibers form a network within the concrete mixture, increasing its internal friction and resistance to flow. As a result, the slump flow decreases and the concrete exhibits increased resistance to deformation, enabling it to maintain its shape and stability even under its own weight. Moreover, melt extract stainless steel fibers can enhance the cohesiveness and filling capability of self-compacting concrete. The fibers create a bridge between the cementitious matrix and the aggregates, improving their bond. This leads to better workability and flowability, allowing the concrete to effortlessly fill intricate and congested areas without the need for vibration or compaction. In conclusion, melt extract stainless steel fibers positively impact the rheology of self-compacting concrete by reducing segregation and bleeding, improving viscosity and yield stress, and enhancing cohesiveness and filling capability. These fibers contribute to the overall performance and durability of self-compacting concrete by providing reinforcement and improving its structural integrity.

- Q: What is the effect of melt extract stainless steel fiber on the durability of tunnel linings?

- The use of melt extract stainless steel fiber in tunnel linings can greatly enhance their durability. These fibers improve the tensile strength and resistance to cracking of the concrete used in tunnel linings. This, in turn, helps to prevent the formation of cracks and fractures, which can compromise the structural integrity of the tunnel lining. Additionally, the stainless steel fibers also enhance the overall ductility and toughness of the concrete, making it more resistant to impact and seismic loads. Overall, the incorporation of melt extract stainless steel fiber in tunnel linings significantly improves their long-term durability and extends their lifespan.

- Q: Is melt extract stainless steel fiber compatible with different types of curing methods?

- Yes, melt extract stainless steel fiber is compatible with different types of curing methods. This type of fiber is specifically designed to enhance the performance and durability of concrete in various applications, including both wet and dry curing methods. It can withstand high temperatures during the curing process without losing its structural integrity or causing any adverse effects on the concrete. Additionally, melt extract stainless steel fiber can be used in conjunction with different curing methods such as steam curing, water curing, and air curing, allowing for flexibility and compatibility with different project requirements.

- Q: Can melt extract stainless steel fiber be used in tunnel shotcreting applications?

- Yes, melt extract stainless steel fiber can be used in tunnel shotcreting applications. Tunnel shotcreting is a process of applying concrete or mortar mix to the walls of a tunnel or underground structure using a spraying technique. The addition of stainless steel fibers to the shotcrete mix can provide reinforcement and improve the overall performance and durability of the sprayed concrete. Melt extract stainless steel fibers are commonly used in shotcrete applications due to their high tensile strength, corrosion resistance, and ability to enhance the post-cracking behavior of the concrete. These fibers are typically made by melting stainless steel and then rapidly cooling it to form fine, elongated fibers. The use of stainless steel fibers in tunnel shotcreting can help mitigate the formation of cracks and control crack propagation, thereby increasing the structural integrity and longevity of the sprayed concrete. The fibers also improve the resistance of the shotcrete to impact, abrasion, and spalling, which are common challenges in tunnel construction. Furthermore, the addition of stainless steel fibers can enhance the overall performance of the shotcrete by reducing shrinkage and improving the bond strength between the shotcrete and the tunnel surface. This is particularly important in tunnel shotcreting applications where the sprayed concrete needs to adhere well to the surrounding rock or soil. In conclusion, melt extract stainless steel fiber can be effectively used in tunnel shotcreting applications to enhance the durability, strength, and performance of the sprayed concrete. Its incorporation can help overcome common challenges in tunnel construction and improve the overall quality of the tunnel walls.

- Q: Does melt extract stainless steel fiber improve the fatigue resistance of concrete?

- Concrete can be improved in terms of fatigue resistance by adding melt extract stainless steel fiber. These fibers are known for their high tensile strength and excellent corrosion resistance. When incorporated into concrete, they serve as reinforcement and help distribute stress more evenly, reducing the chances of cracking and failure under cyclic loading conditions. The inclusion of melt extract stainless steel fiber in concrete significantly boosts its ability to withstand fatigue. These fibers absorb and dissipate energy during loading and unloading cycles, reducing the accumulation of microcracks and increasing the overall durability of the concrete. This enhanced fatigue resistance is particularly advantageous for structures subjected to repetitive or dynamic loading, such as bridges, pavements, and industrial floors. Moreover, melt extract stainless steel fibers possess a high aspect ratio, meaning they have a relatively long length compared to their diameter. This characteristic allows the fibers to effectively bridge cracks that may occur in the concrete, preventing their propagation and enhancing the structural integrity of the material as a whole. In conclusion, the addition of melt extract stainless steel fiber greatly enhances the fatigue resistance of concrete, making it more capable of withstanding cyclic loading. This reinforcement prevents the formation and spread of cracks, resulting in a more durable and long-lasting concrete structure.

Send your message to us

Melt Extract Stainless Steel Fiber Reinforced Construction and Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords