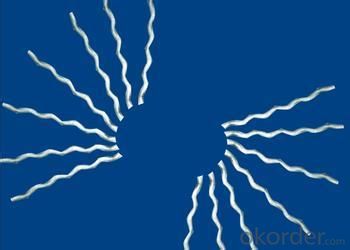

Melt Extract Stainless Steel Fiber Concrete Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Place of Origin: Tianjin, China (Mainland)

Model Number: 0.5

Material: Steel

Production Process: Cold drawn

Lengh: 30

Type: 1

Compressive Strength: >1200MPa

Aspect ratio: 60

Standard: ASTM A820M-11

Section Shape: Circular

Application: Concrete Reinforcement

Packaging & Delivery

| Packaging Details: | 20 kg/Bag,50 bags/Pallet or 1,000kg/ Bulk Bag |

|---|---|

| Delivery Detail: | 1 Month |

Product Description

| Diameter | 0.75 mm | ||

| Length | 60 mm | ||

| Aspect Ratio | 80 | ||

| Tensile strength | 1200 MPa | ||

| Type | Cold drawn Steel Fiber | ||

| End | Hooked-end Steel Fiber | ||

| Glued/Loose | Glued Steel Fiber | ||

| Bending Angle | 45°(min.30°) | ||

| Usage & Performance | Floor:Trafficked areas and Industrial floors | ||

| Shotcrete :Slope stabilization and Final lining | |||

| Precast concrete:Pipe and Railway sleepers | |||

| Packing | Standard Export Pallet Packing | Bag Packing | 20 kg/Bag,50 bags/Pallet |

| Bulk Packing | 1,000kg/ Bulk Bag | ||

| Loading Quantity | 20’GP | 20-25 Tonne/Tonnes | |

| 40’GP | 25-27 Tonne/Tonnes | ||

| 40’HQ | 25-27 Tonne/Tonnes | ||

| MOQ | 1 kg for trial order | ||

| Supply Ability | 10,000 Tonne/Tonnes per Year | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 15 days after receiving deposit or original L/C at sight | ||

| Certification | ISO9001:2000, CE, | ||

| Product | Diameter (mm) | Length (mm) | Aspect Ratio | Type | Packing |

| G-6030 | 0.5 | 30 | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 | 35 | 65 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 | 35 | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 | 60 | 80 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 | 60 | 60 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6030 | 0.5 | 30 | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 | 35 | 65 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 | 35 | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 | 60 | 80 | Loose | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 | 60 | 60 | Loose | 20 kg/Bag, 50 bags/Pallet |

- Q: Can melt extract stainless steel fiber be used in basement walls?

- Yes, melt extract stainless steel fiber can be used in basement walls. Stainless steel fibers are commonly used in construction applications for their high tensile strength and resistance to corrosion. When added to concrete or other building materials, these fibers help improve the overall strength and durability of the structure. In basement walls, where moisture and potential water damage can be a concern, using stainless steel fibers can provide additional reinforcement and enhance the long-term stability of the walls. Additionally, stainless steel fibers can also help reduce the potential for cracking and shrinkage in the concrete, making them a suitable choice for basement walls.

- Q: How does the addition of melt extract stainless steel fiber affect the durability of concrete?

- Concrete's durability can be greatly enhanced by incorporating melt extract stainless steel fiber. These fibers possess high tensile strength, corrosion resistance, and outstanding durability properties. When integrated into the concrete, they create a three-dimensional reinforcement network that greatly improves its resistance to cracking, spalling, and other forms of damage. By acting as reinforcement within the concrete matrix, the stainless steel fibers provide extra strength and toughness. This reinforcement effectively prevents cracks from spreading, thus reducing the risk of structural failure. Additionally, the fibers enhance the concrete's resistance to impact, abrasion, and fatigue, making it more durable in harsh environments or under heavy loads. Moreover, the corrosion resistance of stainless steel fibers ensures the concrete remains robust even in aggressive environments. Unlike traditional steel reinforcement, which is vulnerable to corrosion and can lead to concrete deterioration, stainless steel fibers remain unaffected by moisture, chemicals, and other corrosive agents. Consequently, the concrete's lifespan is extended, and the need for costly repairs or maintenance is reduced. Overall, the addition of melt extract stainless steel fiber significantly improves concrete's durability. It enhances its strength, toughness, resistance to cracking, impact, abrasion, and fatigue, while also providing excellent corrosion resistance. This results in concrete structures that are more resilient, longer-lasting, and more cost-effective in the long run.

- Q: What is the role of melt extract stainless steel fiber in refractory materials?

- The role of melt extract stainless steel fiber in refractory materials is primarily to enhance the mechanical properties and performance of the refractory material. Stainless steel fibers are added to the refractory mix to provide reinforcement and improve its resistance to thermal shock, cracking, and mechanical stress. The melt extract process ensures that the stainless steel fibers have a high degree of purity and uniformity, making them suitable for use in high-temperature applications. These fibers are typically added in small quantities to the refractory mix, but they significantly improve its strength, toughness, and resistance to wear and erosion. Stainless steel fibers also enhance the refractory material's thermal conductivity and dimensional stability, allowing it to withstand extreme temperatures without significant deformation or deterioration. They act as a reinforcement network within the refractory matrix, preventing the propagation of cracks and enhancing its overall durability. Furthermore, stainless steel fibers can improve the refractory material's resistance to chemical attack and corrosion, making it suitable for use in aggressive environments. They can also enhance the refractory's ability to retain heat, improving energy efficiency in various industrial applications. Overall, the addition of melt extract stainless steel fibers in refractory materials significantly enhances their mechanical strength, thermal stability, and resistance to various forms of degradation. This allows refractory materials to withstand harsh operating conditions and prolong their service life, making them essential in industries such as steelmaking, cement production, glass manufacturing, and petrochemical processing.

- Q: How does melt extract stainless steel fiber improve the resistance to spalling in shotcrete?

- Melt extract stainless steel fiber enhances the resistance to spalling in shotcrete by reinforcing the concrete matrix. The fibers are dispersed uniformly throughout the shotcrete, creating a three-dimensional network that improves the overall strength and durability of the material. This reinforcement reduces the formation and propagation of cracks, thereby minimizing the risk of spalling under various loading conditions. Additionally, the stainless steel fibers act as a barrier to inhibit the ingress of moisture and other aggressive substances that can contribute to spalling.

- Q: What are the advantages of using melt extract stainless steel fiber in concrete?

- The advantages of using melt extract stainless steel fiber in concrete include improved crack resistance, increased durability, enhanced flexural strength, reduced shrinkage, and improved resistance to corrosion. Additionally, stainless steel fibers provide better resistance to high temperatures, increased resistance to impact and fatigue loading, and improved resistance to chemical attack.

- Q: How does the addition of melt extract stainless steel fiber affect the drying time of concrete?

- The addition of melt extract stainless steel fiber can have a significant impact on the drying time of concrete. Stainless steel fibers are typically added to concrete mixtures to enhance its mechanical properties and improve its durability. One of the key advantages of using stainless steel fibers is their ability to reduce drying shrinkage. Concrete typically undergoes shrinkage as it dries, which can lead to cracks and other structural issues. The addition of stainless steel fibers helps to restrain this shrinkage, resulting in a more controlled and uniform drying process. The presence of stainless steel fibers also aids in the formation of a more interconnected network within the concrete matrix. This network enhances the concrete's resistance to cracking and improves its overall strength. As a result, the concrete can withstand forces and stresses better, even during the drying phase. Furthermore, stainless steel fibers also contribute to the reduction of plastic shrinkage cracking. This type of cracking occurs during the early stages of concrete drying, when the surface moisture evaporates faster than it can be replaced. By reinforcing the concrete, the stainless steel fibers help to mitigate this cracking, leading to a more efficient and stable drying process. In summary, the addition of melt extract stainless steel fiber can significantly affect the drying time of concrete. By reducing drying shrinkage, enhancing the concrete's mechanical properties, and mitigating cracking, the fibers contribute to a more controlled and efficient drying process, ultimately improving the overall performance and durability of the concrete structure.

- Q: What is the effect of melt extract stainless steel fiber on the durability of shotcrete?

- Melt extract stainless steel fiber has a positive effect on the durability of shotcrete. It enhances the overall strength and crack resistance of the shotcrete, improving its resistance to various external factors such as freeze-thaw cycles, chemical exposure, and abrasion. The incorporation of stainless steel fiber in shotcrete helps to prevent cracking and spalling, resulting in a more durable and long-lasting concrete structure.

- Q: How does melt extract stainless steel fiber improve the resistance to chemical attack in concrete?

- The unique properties and characteristics of melt extract stainless steel fiber are well-known for their ability to enhance the resistance of concrete to chemical attack. When added to concrete mixtures, these stainless steel fibers act as reinforcement, improving the longevity and durability of the concrete structure. One way in which melt extract stainless steel fiber enhances resistance to chemical attack is by creating a physical barrier against corrosive substances. Concrete is susceptible to deterioration over time due to the penetration of acids, alkalis, and chlorides. However, the addition of stainless steel fibers creates a network of reinforcement within the concrete, acting as a protective barrier against chemical intrusion. This reduces concrete permeability and prevents corrosive substances from damaging the underlying steel reinforcement. Additionally, melt extract stainless steel fiber improves resistance to chemical attack by enhancing the mechanical properties of the concrete. The inclusion of stainless steel fibers increases flexural strength, tensile strength, and impact resistance, making the concrete more resistant to cracking and spalling caused by chemical exposure. This improved mechanical performance helps maintain the integrity of the concrete structure and prevents corrosive substances from infiltrating through cracks and fissures. Moreover, stainless steel fibers also play a crucial role in minimizing the effects of chemical attack by reducing the formation of microcracks in the concrete. Chemical attack can lead to the formation of cracks and fractures, accelerating the deterioration process. However, the presence of stainless steel fibers helps distribute stress and load more evenly, preventing the concentration of forces that cause crack formation. By minimizing the formation of microcracks, stainless steel fibers effectively reduce the vulnerability of the concrete to chemical attack, enhancing its overall durability. In conclusion, melt extract stainless steel fiber enhances the resistance of concrete to chemical attack by forming a physical barrier, improving mechanical properties, and minimizing microcrack formation. These combined effects result in a more durable and long-lasting concrete structure that can better withstand the detrimental effects of chemical exposure.

- Q: Can melt extract stainless steel fiber be used in tunneling and mining applications?

- Certainly! Melt extract stainless steel fiber is applicable in tunneling and mining operations. This particular fiber is renowned for its exceptional strength, durability, and ability to resist corrosion. As a result, it is well-suited for challenging environments like tunnels and mines. It can reinforce various construction materials, including concrete structures and shotcrete, which improves their strength and prevents cracking and deterioration. By incorporating stainless steel fiber, the overall stability and safety of the tunnel or mine can be enhanced by reducing the risk of structural failure or collapse. Moreover, this fiber can endure high temperatures, fire, and abrasive substances, making it a reliable choice for these applications. Ultimately, melt extract stainless steel fiber is an invaluable material that significantly improves the performance and lifespan of tunneling and mining projects.

- Q: What is the effect of melt extract stainless steel fiber on the shrinkage of concrete?

- The impact of using melt extract stainless steel fiber on concrete shrinkage can be significant. When added to the concrete mix, stainless steel fibers serve as reinforcement and aid in reducing shrinkage. Concrete shrinkage occurs as a result of moisture loss during the curing process, which can cause cracks and decreased durability. By integrating melt extract stainless steel fibers into the concrete mixture, a network of reinforcement is formed throughout the material. This reinforcement helps in distributing and controlling the forces of shrinkage, resulting in reduced overall shrinkage and improved resistance to cracking. Furthermore, the presence of stainless steel fibers enhances the tensile strength of the concrete, which further contributes to its resistance against shrinkage. These fibers act as small reinforcements, bridging any potential cracks and preventing their propagation, thereby minimizing shrinkage-induced cracking. Moreover, the high corrosion resistance of stainless steel fibers ensures their long-term functionality in concrete. This is especially crucial in environments with high moisture or chloride exposure, as conventional steel reinforcement may corrode over time, leading to increased shrinkage and decreased structural integrity. In conclusion, incorporating melt extract stainless steel fibers in concrete effectively mitigates shrinkage by providing reinforcement, improving crack resistance, and enhancing overall durability. This results in a more stable and long-lasting concrete structure.

Send your message to us

Melt Extract Stainless Steel Fiber Concrete Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords