Melt Extract Stainless Steel Fiber - Straight Type CE Approved High Quality Hooked

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

Steel fiber types includs,

a) Hooked ends steel fiber

b) Flat head steel fiber

c) Needle-flat steel fiber

d) Wavy steel fiber

e) Xorex steel fiber

f) Micro-steel fiber

g) stainless steel fiber

Application of Daye steel fiber:

A. Tunnel pre-treatment(primary support)

B. Tunnel forming(permanent lining)

C. Slope stabilization

D. Ditch excavation support

E. Industrial floor

F. Precast concrete element

G. Concrete restoration

H. High performance concrete

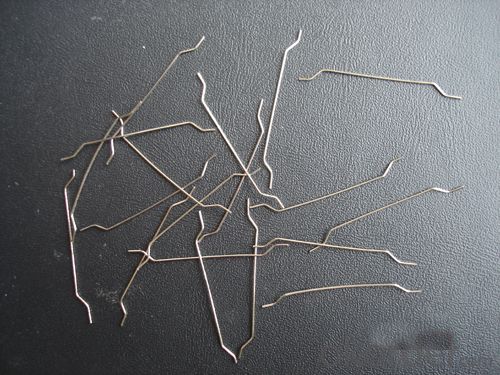

Picture

Steel fiber straight type

Wavy steel fiber

Xorex steel fiber

Micro-steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Can melt extract stainless steel fiber improve the durability of concrete in acidic environments?

- Indeed, the durability of concrete in acidic environments can be improved by using melt extract stainless steel fiber. The exceptional corrosion resistance properties of stainless steel fibers make them highly resistant to chemical attacks, even in acidic conditions. When added to concrete mixtures, these fibers act as reinforcement, enhancing the overall strength and durability of the concrete. In acidic environments, concrete tends to deteriorate due to chemical reactions between acidic substances and the cement paste. This deterioration can result in the loss of structural integrity and premature failure of the concrete. However, incorporating melt extract stainless steel fibers into the concrete significantly improves its corrosion resistance, thereby prolonging its service life in acidic conditions. The inclusion of stainless steel fibers creates a protective barrier within the concrete, preventing the penetration of acidic substances and minimizing chemical reactions. Moreover, these fibers improve the strength and toughness of the concrete matrix, making it more resistant to cracking and spalling that may occur in acidic environments. Additionally, melt extract stainless steel fibers enhance the overall durability of concrete by increasing its resistance to other forms of deterioration, such as freeze-thaw cycles, abrasion, and impact. This further contributes to the longevity of the concrete in acidic environments. Overall, the addition of melt extract stainless steel fiber to concrete mixtures offers a cost-effective solution for enhancing performance and extending the service life of concrete structures exposed to acidic conditions.

- Q: What is a steel fiber cement?

- Fiber concrete is a new kind of multiphase composite material, which is made up of short steel fiber reinforced by random distribution in ordinary concrete. The chaos to the distribution of steel fiber can be formed effectively hinder the propagation of concrete internal micro cracks and macro cracks, improve concrete tensile strength, bending strength, impact resistance and fatigue performance, has good ductility.

- Q: Can melt extract stainless steel fiber be used in tunnel segmental lining rehabilitation?

- Yes, melt extract stainless steel fiber can be used in tunnel segmental lining rehabilitation. It is commonly used as a reinforcement material in concrete to improve its strength, durability, and resistance to cracking. In tunnel segmental lining rehabilitation, where concrete structures need to withstand high loads and potential damage, the use of stainless steel fiber can provide significant benefits in terms of structural integrity and longevity.

- Q: Can melt extract stainless steel fiber improve the ductility of concrete?

- Yes, melt extract stainless steel fiber can improve the ductility of concrete. Melt extract stainless steel fibers are added to concrete mixtures to enhance its mechanical properties and improve its performance under various loading conditions. The addition of these fibers helps to increase the ductility of concrete, which refers to its ability to deform without fracturing. The stainless steel fibers act as reinforcement within the concrete matrix, providing additional strength and flexibility. When concrete undergoes tensile stresses, which can lead to cracking and failure, the fibers help to distribute the load and prevent the propagation of cracks. This enhances the overall ductility of the concrete by allowing it to sustain greater deformations before failure. Furthermore, the addition of melt extract stainless steel fibers also improves the impact resistance and durability of concrete. This is particularly beneficial in applications where the concrete is exposed to heavy loads, seismic activity, or other dynamic forces. In conclusion, the use of melt extract stainless steel fiber can indeed improve the ductility of concrete by enhancing its resistance to cracking and increasing its ability to deform without fracturing.

- Q: What is the effect of melt extract stainless steel fiber on the permeability of asphalt mixtures?

- By incorporating melt extract stainless steel fiber into asphalt mixtures, a notable reduction in permeability can be achieved. When stainless steel fibers are introduced into the asphalt mixture, they establish a three-dimensional network within the asphalt matrix. This network serves to enhance the cohesion and strength of the asphalt mixture. The stainless steel fibers function as reinforcement, forming a barrier that limits the movement of water or other fluids through the asphalt mixture. Consequently, the permeability of the mixture is diminished, rendering it more resistant to water damage and enhancing its overall durability. Furthermore, the inclusion of stainless steel fibers aids in preventing the formation of cracks and minimizing the propagation of existing cracks within the asphalt mixture. This further bolsters the performance and lifespan of the asphalt pavement. In summary, the introduction of melt extract stainless steel fiber into asphalt mixtures yields a positive impact on permeability, reducing it and elevating the overall durability and performance of the asphalt pavement.

- Q: Is melt extract stainless steel fiber compatible with different types of aggregates?

- Different types of aggregates are compatible with melt extract stainless steel fiber. In concrete, stainless steel fiber is often utilized as a reinforcing material to strengthen its tensile strength, durability, and resistance to cracking. It can be combined with various aggregates including sand, gravel, crushed stone, or recycled materials without compromising compatibility. The concrete mixture is evenly infused with these fibers, leading to enhanced overall performance and prevention of crack formation. Furthermore, the stainless steel fibers exhibit no chemical reactions with the aggregates, thus guaranteeing long-term stability and compatibility.

- Q: Can melt extract stainless steel fiber be used in parking garage construction?

- Yes, melt extract stainless steel fiber can be used in parking garage construction.

- Q: Can melt extract stainless steel fiber be used in foundation slabs?

- Yes, melt extract stainless steel fiber can be used in foundation slabs. These fibers provide reinforcement and improve the overall strength and durability of the concrete. They are commonly used in industrial and commercial applications where heavy loads and high traffic are expected. The stainless steel fibers are resistant to corrosion and can withstand harsh environmental conditions. They also help to control cracking and improve the overall performance of the foundation slab.

- Q: Is melt extract stainless steel fiber suitable for use in tunnel lining construction?

- Yes, melt extract stainless steel fiber is suitable for use in tunnel lining construction. It provides enhanced strength, durability, and resistance to corrosion, making it an ideal choice for reinforcing concrete in tunnels.

- Q: How does melt extract stainless steel fiber enhance the durability of composite materials?

- Melt extract stainless steel fiber enhances the durability of composite materials in several ways. Firstly, the addition of stainless steel fibers improves the overall mechanical strength and toughness of the composite. The fibers act as reinforcement, providing additional structural integrity and preventing crack propagation. This results in a composite material that is more resistant to bending, impact, and fatigue, thus increasing its durability. Furthermore, the corrosion resistance of stainless steel fibers enhances the durability of the composite in harsh environments. Stainless steel is known for its excellent resistance to corrosion, even in acidic or alkaline conditions. By incorporating stainless steel fibers, the composite material becomes more resistant to chemical degradation, ensuring its longevity and performance over time. Another important aspect is the thermal stability that stainless steel fibers provide to the composite. Stainless steel has a high melting point and can withstand extreme temperatures, making it ideal for applications that require resistance to heat and fire. By incorporating melt extract stainless steel fibers, the composite material becomes more resistant to thermal degradation, ensuring its durability even in high-temperature environments. Lastly, the dimensional stability of composite materials is improved with the addition of stainless steel fibers. These fibers help to minimize dimensional changes due to temperature variations, reducing the risk of warping or distortion. This enhanced dimensional stability enhances the overall durability of the composite, making it suitable for a wide range of applications where precision and stability are crucial. In summary, melt extract stainless steel fiber enhances the durability of composite materials through improved mechanical strength, corrosion resistance, thermal stability, and dimensional stability. These properties make the composite material more robust, long-lasting, and capable of withstanding various environmental and operational conditions.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type CE Approved High Quality Hooked

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords