Steel Fiber Straight Type CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

The raw material is stainless steel ingots, using electric stoves which melt the stainless steel ingots to become 1500 ~ 1600 ℃ steel liquid, and then with a grooved high speed rotating melt-extracting steel wheel which produces wires that meets are our customers’ specific requirements. When melting down to a wheel steel liquid surface, the liquid steel blow out by slot with centrifugal force at extremely high speed with cooling forming. Melting wheels with water keep the cooling speed. This method is done to produce different material, different sizes of steel fiber.

| SIZE | CHEMIC ELEMENT(%) | ||||||

| C | P | Mn | Si | Cr | Ni | Al | |

| AISI330 | ≤0.40 | ≤0.04 | ≤2.00 | ≤0.75 | 17~20 | 33~37 | |

| AISI310 | ≤0.40 | ≤0.04 | ≤2.00 | ≤1.50 | 24~26 | 19~22 | |

| AISI316 | ≤0.40 | ≤0.04 | ≤2.00 | ≤1.00 | 16~18 | 10~14 | |

| AISI314 | ≤0.40 | ≤0.045 | ≤2.00 | 1.5-3.0 | 23~26 | 19~22 | |

| AISI309 | ≤0.40 | ≤0.04 | ≤2.00 | ≤1.00 | 22~24 | 12~15 | |

| AISI304 | ≤0.40 | ≤0.04 | ≤2.00 | ≤2.00 | 18~20 | 8~10 | |

| AISI301 | ≤0.40 | ≤0.04 | ≤2.00 | ≤2.00 | 16~18 | 6~8 | |

| AISI201 | ≤0.40 | ≤0.06 | 5.5~7.5 | ≤1.00 | 16~18 | 3.5~5.5 | |

| AISI446 | ≤0.40 | ≤0.04 | ≤1.50 | ≤2.00 | 23~27 | ||

| AISI430 | ≤0.40 | ≤0.03 | ≤1.00 | ≤2.00 | 16~18 | ||

| NAS430A | ≤0.40 | ≤0.03 | ≤0.50 | ≤0.50 | 16~18 | 2~4 | |

| SIZE(mm) | ||||

| length | 20 | 25 | 30 | 35 |

| width | 0.75~1.5 | 0.75~1.5 | 0.75~1.5 | 0.75~1.5 |

| thickness | 0.2~0.75 | 0.2~0.75 | 0.2~0.75 | 0.2~0.75 |

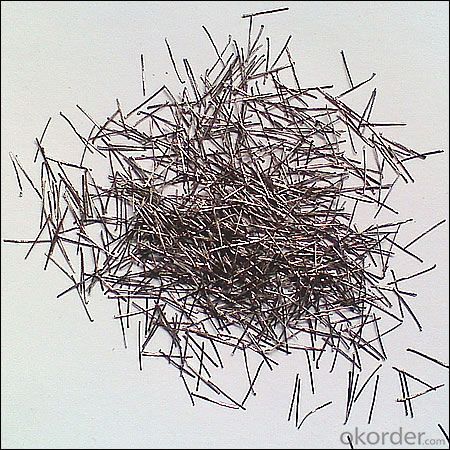

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

- Q: Can melt extract stainless steel fiber be used in marine concrete applications?

- Indeed, melt extract stainless steel fiber is suitable for utilization in marine concrete applications. This particular fiber variant has been meticulously crafted to endure the severe circumstances prevalent in marine environments, including the detrimental effects of saltwater and other corrosive substances. The stainless steel composition employed in these fibers showcases exceptional resistance to corrosion, rendering it an optimal selection for marine concrete applications where endurance and longevity are of utmost importance. Furthermore, the inclusion of stainless steel fibers in marine concrete has the potential to augment the overall robustness and resistance to cracks, thereby offering supplementary safeguarding against the destructive impact of waves, tides, and other forces characteristic of marine settings.

- Q: What is the effect of melt extract stainless steel fiber on the crack width of concrete?

- The effect of melt extract stainless steel fiber on the crack width of concrete is significant. When added to concrete mixtures, the stainless steel fibers help to improve the overall tensile strength and ductility of the concrete. This enhanced strength and ductility result in reduced crack widths in the hardened concrete. The stainless steel fibers act as reinforcement within the concrete matrix, effectively bridging the cracks and preventing their propagation. The fibers distribute the stress more evenly throughout the concrete, reducing localized cracking and minimizing the crack width. This is particularly important in situations where concrete is subjected to external loads, such as in structural elements or pavements. Additionally, the corrosion resistance of stainless steel fibers ensures their long-term effectiveness in preventing crack widening. Unlike other types of fibers, stainless steel fibers do not degrade or weaken over time due to environmental factors, such as moisture or chemical exposure. Overall, the incorporation of melt extract stainless steel fiber in concrete leads to a significant reduction in crack width, resulting in improved durability and increased service life of the concrete structures.

- Q: Can melt extract stainless steel fiber be used in the construction of precast concrete walls?

- Yes, melt extract stainless steel fiber can be used in the construction of precast concrete walls. These fibers can enhance the strength and durability of the concrete, reduce cracking, and improve the overall performance of the precast walls.

- Q: Can melt extract stainless steel fiber improve the fatigue resistance of concrete?

- Yes, melt extract stainless steel fiber can improve the fatigue resistance of concrete. Stainless steel fibers are commonly used as reinforcement in concrete to enhance its mechanical properties and durability. The addition of stainless steel fibers improves the cracking and fatigue resistance of concrete by reinforcing the matrix and increasing its ability to withstand cyclic loading and stress. These fibers act as reinforcement by bridging cracks and preventing their propagation, thereby improving the overall fatigue performance of concrete. Melt extract stainless steel fibers have high tensile strength and excellent corrosion resistance, making them especially effective in enhancing the fatigue resistance of concrete structures.

- Q: Is melt extract stainless steel fiber compatible with various types of admixtures?

- Yes, melt extract stainless steel fiber is generally compatible with various types of admixtures. The unique properties of stainless steel fibers, such as high tensile strength and corrosion resistance, allow them to effectively reinforce concrete and enhance its performance, regardless of the type of admixture used.

- Q: Steel fiber concrete structure and steel reinforced concrete structure belong to concrete mix structure?

- Concrete is the abbreviation of concrete. See unknown.Does the steel fiber concrete structure and the reinforced concrete structure all belong to the concrete structure?.

- Q: How does the addition of melt extract stainless steel fiber affect the toughness of concrete?

- The addition of melt extract stainless steel fiber significantly improves the toughness of concrete. Stainless steel fibers are added to concrete mixtures to enhance its resistance to cracking and improve its overall durability. These fibers act as reinforcements within the concrete matrix, effectively increasing its tensile strength and preventing the propagation of cracks. The melt extract stainless steel fibers are specifically designed to have a high aspect ratio and excellent bonding properties with the concrete matrix. This ensures that the fibers are well-distributed throughout the mixture and can effectively bridge any microcracks that may form during the curing process or due to external factors. By adding melt extract stainless steel fibers, the toughness of concrete is substantially enhanced. The fibers reinforce the concrete, making it more resistant to impact, abrasion, and flexural stress. This increased toughness not only improves the lifespan of the concrete structure but also enhances its resistance to various environmental factors such as freeze-thaw cycles and chemical degradation. Furthermore, the addition of melt extract stainless steel fibers improves the post-cracking behavior of concrete. When cracks do occur, the fibers help to distribute the stress more evenly, reducing the width and length of the cracks. This prevents the cracks from becoming larger and compromising the structural integrity of the concrete. In summary, the addition of melt extract stainless steel fiber greatly enhances the toughness of concrete by increasing its tensile strength, improving its resistance to cracking, and enhancing its overall durability. This results in a more robust and long-lasting concrete structure that can withstand various external forces and environmental conditions.

- Q: What is the lifespan of melt extract stainless steel fiber in concrete?

- The durability and lifespan of melt extract stainless steel fiber in concrete can vary due to several factors, including fiber quality, application, and environmental conditions. Generally, melt extract stainless steel fibers are known for their long lifespan and resistance to corrosion. Under normal concrete conditions, the lifespan of melt extract stainless steel fiber can range from 20 to 50 years. This is possible because stainless steel has high tensile strength and corrosion resistance, enabling it to withstand harsh concrete conditions such as moisture, chemicals, and temperature changes. However, it's important to consider that the lifespan can be influenced by factors like fiber quality, concrete mix design, and the maintenance of the concrete structure. Proper installation, curing methods, regular maintenance, and inspections can significantly prolong the lifespan of stainless steel fiber in concrete. Additionally, the specific application of the concrete, such as heavy traffic areas or exposure to extreme weather conditions, can impact the lifespan of the stainless steel fiber. In such cases, applying surface coatings or sealants may be necessary to further protect the stainless steel fiber and enhance its longevity. Overall, melt extract stainless steel fiber is a reliable and durable reinforcement material for concrete structures. With proper care and maintenance, it can provide a lifespan of 20 to 50 years or even longer.

- Q: Is melt extract stainless steel fiber compatible with different types of admixtures?

- Different types of admixtures can be used with melt extract stainless steel fiber, as it is known for enhancing the mechanical properties of concrete, such as its tensile strength and durability. Adding admixtures to concrete can further enhance its performance by modifying properties like workability, setting time, and water-cement ratio. Melt extract stainless steel fibers are versatile and can be combined with different admixtures. For instance, if a plasticizing admixture is added to improve workability, the stainless steel fibers can still be incorporated without any negative consequences. Likewise, if a superplasticizer is utilized to increase concrete flowability, the stainless steel fibers can be included without compromising the effectiveness of the admixture. It is essential to keep in mind that the compatibility between melt extract stainless steel fibers and admixtures may vary depending on the specific fibers and admixtures used. Therefore, it is always advisable to consult the manufacturer's guidelines and conduct proper testing to ensure compatibility and achieve the desired concrete properties.

- Q: Does melt extract stainless steel fiber improve the resistance to acid attack in concrete?

- Concrete, when melt extract stainless steel fiber is added, exhibits improved resistance to acid attack. Renowned for their exceptional corrosion resistance, stainless steel fibers offer enhanced protection against acid attack in concrete. By enveloping the concrete matrix, these fibers create a safeguarding barrier, hindering acid infiltration and diminishing corrosion hazards. Moreover, they bolster the concrete's durability and lifespan, rendering it more impervious to acid-induced deterioration. Consequently, the incorporation of melt extract stainless steel fiber in concrete results in a substantial enhancement of its acid attack resistance.

Send your message to us

Steel Fiber Straight Type CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords