Melt Extract Stainless Steel Fiber - Straight Type from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

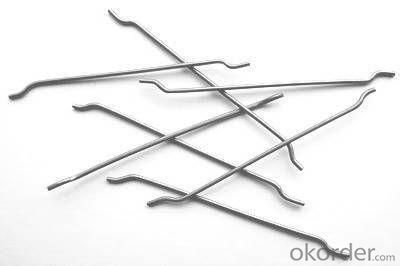

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Can melt extract stainless steel fiber be used in marine structures?

- Yes, melt extract stainless steel fiber can be used in marine structures. Its corrosion resistance properties make it suitable for applications in marine environments where it can withstand exposure to saltwater and moisture without losing its structural integrity.

- Q: Can melt extract stainless steel fiber be used in railway sleepers?

- Yes, melt extract stainless steel fiber can be used in railway sleepers. Stainless steel fiber is a high-strength material that offers excellent resistance to corrosion and fatigue. Its use in railway sleepers can enhance the overall strength and durability of the sleepers, making them suitable for heavy train loads and prolonged service life. The melt extract process ensures that the stainless steel fibers have a uniform and consistent shape, which further enhances their performance and reliability. Additionally, the use of stainless steel fiber can help prevent the formation of cracks and improve the resistance to thermal expansion and contraction, making it an ideal choice for railway sleepers.

- Q: What is steel fiber? What's the use of it?

- Compared with ordinary concrete, not only can improve the tensile, shear, bending, anti-wear and anti cracking performance, but also can greatly enhance the fracture toughness of concrete and impact resistance, improve fatigue properties and durability of structures. Especially the toughness can be increased L020 times.

- Q: How does melt extract stainless steel fiber affect the modulus of elasticity of concrete?

- Melt extract stainless steel fiber can significantly increase the modulus of elasticity of concrete. The addition of these fibers improves the tensile strength and overall durability of the concrete, leading to a stiffer and more rigid material. This enhanced modulus of elasticity allows the concrete to better withstand external forces and minimize cracking or deformation under stress.

- Q: Steel fiber prices? (recent price)

- Wire cut type: general price at 9000-14000 yuan / ton. (packaging and materials are not the same, the price difference is also large, about 8000 is bulk, about 14000 is glue dip loading)

- Q: Difference between cement manhole cover and steel fiber manhole cover

- The material is different, the thickness is different, the structure is different, the weight is also different.

- Q: Can melt extract stainless steel fiber be used in lightweight concrete?

- Yes, melt extract stainless steel fiber can be used in lightweight concrete. Stainless steel fiber is added to concrete to enhance its mechanical properties, such as improving its tensile strength, flexural strength, and impact resistance. Lightweight concrete, on the other hand, is a type of concrete that incorporates lightweight aggregates or foaming agents to reduce its density and improve its thermal and acoustic properties. By adding melt extract stainless steel fiber to lightweight concrete, it can provide additional reinforcement and enhance its performance. The stainless steel fibers help to distribute the stresses more evenly throughout the concrete matrix, making it more resistant to cracking and improving its overall durability. Additionally, the use of stainless steel fibers can also increase the ductility of lightweight concrete, allowing it to better withstand dynamic loads and reduce the risk of sudden failure. In conclusion, melt extract stainless steel fiber is a suitable option for reinforcing lightweight concrete, as it can improve its mechanical properties and enhance its durability.

- Q: What is the typical aspect ratio of melt extract stainless steel fibers?

- Melt extract stainless steel fibers typically have an aspect ratio ranging from 20:1 to 100:1, indicating that the fiber's length is 20 to 100 times larger than its diameter. Consequently, the aspect ratio significantly influences the mechanical properties and performance of stainless steel fibers across different applications. As the aspect ratio increases, so does the reinforcing effect of the fibers, resulting in improved strength and durability of composites or concrete materials.

- Q: Can melt extract stainless steel fiber be used in concrete pipes and culverts?

- Yes, melt extract stainless steel fiber can be used in concrete pipes and culverts. The addition of stainless steel fiber enhances the strength, durability, and crack resistance of the concrete, making it better equipped to withstand the demanding conditions and stresses typically encountered in pipes and culverts.

- Q: Can melt extract stainless steel fiber be used in tunnel linings or underground structures?

- Yes, melt extract stainless steel fiber can be used in tunnel linings or underground structures. This type of fiber is known for its high strength and corrosion resistance, making it suitable for reinforcing concrete in these applications. It helps improve the durability and structural integrity of tunnel linings and underground structures, enhancing their overall performance and longevity.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type from CNBM International

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords