Steel Deformed Rebar In Coil Small Sizes for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Deformed Rebar In Coil Small Sizes for Construction Description:

Steel deformed rebar in coil small sizes for construction is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel deformed rebar in coil small sizes for construction is usually made of structural steel and is used in construction and civil engineering. The steel deformed rebar in coil small sizes for construction resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel deformed rebar in coil small sizes for construction theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel Deformed Rebar In Coil Small Sizes for Construction:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

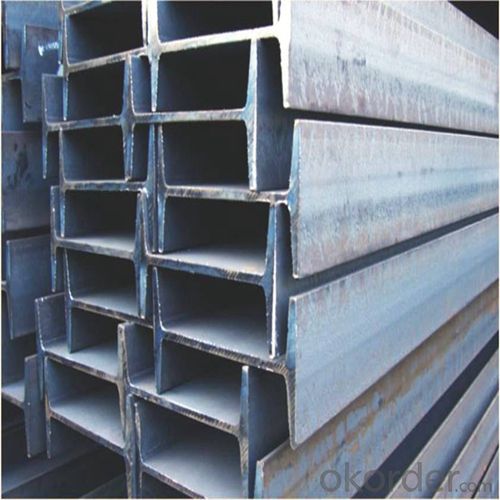

3. Steel Deformed Rebar In Coil Small Sizes for Construction Images:

4. Steel Deformed Rebar In Coil Small Sizes for Construction Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: What is the corrosion resistance of steel rebars?

- The corrosion resistance of steel rebars is generally high due to the presence of a protective oxide layer on the surface of the steel. However, in certain environments, such as those with high levels of moisture or exposure to corrosive substances, the rebars may be susceptible to corrosion. Therefore, additional measures such as proper concrete cover, epoxy coating, or galvanization are often employed to enhance the corrosion resistance of steel rebars.

- Q: What are the methods used for corrosion protection of steel rebars?

- Steel rebars can be protected from corrosion using various methods. Firstly, a commonly used method is to apply a protective coating on the surface of the steel rebar. This coating acts as a barrier, stopping moisture and oxygen from reaching the steel surface and causing corrosion. Different techniques like hot-dip galvanizing, epoxy coatings, or fusion-bonded epoxy coatings can be employed to apply these coatings. Another method is cathodic protection, which involves using sacrificial anodes or impressed current systems. Sacrificial anodes, made of a more reactive metal like zinc or magnesium, corrode over time instead of the steel rebar, ensuring its protection. Impressed current systems utilize an external power source to provide a protective current to the steel rebar, preventing corrosion. A simple but effective method is to provide a sufficient concrete cover over the steel rebar. This concrete acts as a physical barrier, shielding the steel from the environment. It is critical to design the thickness of the concrete cover according to specific standards to guarantee proper protection. Corrosion inhibitors can also be employed by adding them to the concrete mix or applying them on the surface of the steel rebar. These inhibitors work by reducing the corrosive effects of moisture and oxygen on the steel surface. They can be organic or inorganic compounds that form a protective layer, inhibiting the corrosion process. Lastly, proper design and construction practices are crucial for corrosion protection. This includes avoiding the use of dissimilar metals that can cause galvanic corrosion, ensuring proper drainage to prevent water accumulation, and taking measures to minimize exposure to corrosive environments. It is important to note that a combination of these methods is often used to provide optimal corrosion protection for steel rebars, depending on the specific project requirements and environmental conditions.

- Q: What is the tensile strength of different grades of steel rebars?

- The tensile strength of different grades of steel rebars can vary depending on the specific grade. Generally, steel rebars range in tensile strength from 400 to 600 megapascals (MPa) for lower grade rebars, while higher grade rebars can have tensile strengths ranging from 600 to 900 MPa or even higher.

- Q: Can steel rebars be used in seismic zone areas?

- Yes, steel rebars can be used in seismic zone areas. Steel rebars are commonly used in construction projects in seismic zones because of their high tensile strength and ductility, which allow them to withstand and absorb the forces generated during seismic events. Additionally, proper design and installation techniques, such as spacing, anchoring, and lap lengths, must be followed to ensure the structural integrity of the reinforced concrete in seismic zones.

- Q: Can steel rebars be used in the construction of water treatment plants?

- Yes, steel rebars can be used in the construction of water treatment plants. Steel rebars are commonly used in the construction industry to reinforce concrete structures, and water treatment plants often require robust and durable infrastructure. Steel rebars provide strength and stability to the concrete components, making them suitable for use in the construction of water treatment plants.

- Q: The effect of adding alum on thread steel

- If the steel is a tiger, so is the wing steel containing vanadium vanadium, like the tiger wings. Only a few percent of vanadium in the steel, can make the elastic strength of steel, increase abrasion resistance and spalling resistance excellent, high temperature resistance and resistance in the car, no wonder the bitterly cold, aviation, railway, electronics, defense industry and other departments, can be seen everywhere traces of vanadium. In addition, vanadium oxide has become one of the best catalysts in the chemical industry, called vanadium, the "chemical bread". Mainly used in the manufacture of high speed cutting steel and other alloy steels and catalysts. The vanadium doped vanadium steel can be made into steel. A more compact structure than ordinary steel vanadium steel, toughness, elasticity and higher mechanical strength. Preparation of vanadium steel penetrators, can penetrate 40 cm thick steel plate. However, in the iron and steel industry, is not the pure metal vanadium steel to make vanadium steel, the vanadium ore smelting vanadium steel.

- Q: How do steel rebars affect the bond strength between concrete and reinforcement?

- Steel rebars have a significant positive impact on the bond strength between concrete and reinforcement. When embedded in concrete, rebars enhance the structural integrity by creating a mechanical bond. The rough texture of rebars provides a larger surface area for the concrete to adhere to, improving the bond strength. This bond is crucial in transferring forces between the two materials, ensuring the reinforced concrete can withstand loads and maintain its stability.

- Q: What are the guidelines for handling and disposing of steel rebars after demolition?

- The guidelines for handling and disposing of steel rebars after demolition typically involve several steps. Firstly, the rebars should be carefully removed from the demolished structure using appropriate tools and equipment to ensure worker safety. Once removed, the rebars should be inspected for any damages or contaminants that may affect their reuse or recycling potential. If the rebars are in good condition, they can be cleaned and stored for future use in construction projects. However, if they are damaged or cannot be reused, they should be properly recycled. This involves sorting them based on their grade and size before sending them to a recycling facility. If recycling is not possible, the rebars should be disposed of in a designated landfill or waste management facility following local regulations and guidelines to minimize environmental impact. It is crucial to follow these guidelines to promote sustainable practices and reduce waste in the construction industry.

- Q: How are steel rebars classified based on grades?

- The strength of steel rebars is determined by their grade, which is based on their minimum yield strength. Steel rebars are classified into different grades to indicate their ability to withstand stress and loads. Grade 40, Grade 60, and Grade 75 are the most commonly used grades for steel rebars. Grade 40 rebars have a minimum yield strength of 40,000 psi and are typically used in general construction projects where high strength is not the main requirement. They are suitable for light to moderate load-bearing structures such as residential buildings, sidewalks, and driveways. Grade 60 rebars, with a minimum yield strength of 60,000 psi, are the most widely used for construction purposes. They can be applied in a wide range of applications and are commonly used in reinforced concrete structures, bridges, highways, and commercial buildings. Grade 60 rebars provide the necessary strength to withstand heavy loads and seismic forces. Grade 75 rebars, with a minimum yield strength of 75,000 psi, are designed for high-stress applications. They are mainly used in large-scale infrastructure projects, including high-rise buildings, dams, and heavy industrial structures. Grade 75 rebars offer exceptional strength and durability, making them suitable for projects that require superior load-bearing capacity and resistance to extreme conditions. It is important to note that the specific requirements and standards for steel rebars may vary among different countries and regions. Therefore, it is crucial to adhere to local codes and regulations to determine the appropriate grade of steel rebar for each construction project.

- Q: How are steel rebars affected by chemical exposure?

- Steel rebars can be affected by chemical exposure in several ways. Certain chemicals, such as acids, alkalis, and chlorides, can cause corrosion of the rebar, leading to a reduction in its strength and durability. The chemical reaction between the rebar and the corrosive substances can result in the formation of rust, which can weaken the steel and compromise the structural integrity of the reinforced concrete. Therefore, it is crucial to protect steel rebars from chemical exposure by using appropriate coatings or by ensuring proper concrete cover to prevent corrosion and maintain the long-term performance of the structure.

Send your message to us

Steel Deformed Rebar In Coil Small Sizes for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords