Hot Rolled GB Standard Deformed Steel Rebars for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled GB Standard Deformed Steel Rebars for Construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled GB Standard Deformed Steel Rebars for Construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

1. Supporting members, most commonly in the house raising industry to strengthen timber bears under houses. Transmission line towers, etc

2. Prefabricated structure

3. Medium scale bridges

4. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

Hot Rolled GB Standard Deformed Steel Rebars for Construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Hot Rolled Equal Angle Steel Bars for Strcuture are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

1. Supporting members, most commonly in the house raising industry to strengthen timber bears under houses. Transmission line towers, etc

2. Prefabricated structure

3. Medium scale bridges

4. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

High Quality Hot Rolled Equal Angle Steel Bars for Constrcution are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Hot Rolled GB Standard Deformed Steel Rebars for Construction:

Standard | GB UK USA | HRB335 HRB400 HRB500 G460B, B500A, B500B,B500C GR40, GR60 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Packing | Export standard packing: wrapped by wire rod in bundles | ||

Each bundle weight | 2-3MT, or as required | ||

Trade terms | FOB, CFR, CIF | ||

Payment terms | TT payment in advance or Irrevocable LC at sight. | ||

Delivery Detail | within 45 days after received advanced payment or LC. | ||

Brand name | DRAGON | ||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2.00 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

50 | 1964 | 15.42 | 185.04 | 5.40 |

Chemical Composition: (Please kindly find our chemistry of our material based on JIS as below for your information)

JISG3112 SD390 | Chemical Composition | ||||

C | Mn | Si | S | P | |

0.22 | 1.38 | 0.4 | 0.014 | 0.022 | |

Physical capability | |||||

Yield Strength(N/cm²) | Tensile Strength(N/cm²) | Elongation (%) | |||

620 | ≥400 | 21 | |||

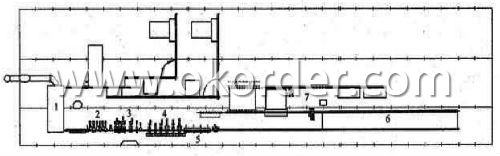

The production process of Steel Rebar

1-Waling beam furnace 2-Roughing rolling group 3-Intermediate rolling train

4-Finishing rolling group 5-Water-cooling device 6-Walking beam cooler

7-Finishing equipment(including the cold scale shear,short feet collection system,

automatic counting device,bundling machine, collect bench)

Usage and Applications of Hot Rolled GB Standard Deformed Steel Rebars for Construction:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Hot Rolled GB Standard Deformed Steel Rebars for Construction:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Price: Keep lower operating costs so as to offer competitive price for our clients

Deformed Steel Rebars according to Korean standard

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q: What are the listed companies that produce wire rod and thread steel?

- The wire in iron and steel usually refers to a coil of wire material with a diameter of 5.5-14. Most of the use of wire coil machine rolled coil supply, it is also known as wire rod or coil. Wire rod is one of the varieties of steel with great dosage. After rolling, it can be directly used for reinforcement and welding structure of reinforced soil, and can also be used again and again. For example, by drawing into a variety of specifications of steel wire, steel wire rope, and then twisted into woven steel wire and winding and heat treatment to the spring; hot and cold forged into cold forging and rolling into rivets and bolts, screws and so on; by cutting into the heat treatment made of mechanical parts or tools; a common wire made of quality carbon steel and carbon steel.

- Q: How are steel rebars protected from vandalism during construction?

- Steel rebars are often protected from vandalism during construction by implementing security measures such as fencing around the construction site, hiring security personnel to monitor the area, and installing surveillance cameras. Additionally, construction companies may choose to store the rebars in secure locations within the site or cover them with protective materials to deter potential vandals.

- Q: How do steel rebars impact the overall construction timeline?

- Steel rebars can have a significant impact on the overall construction timeline. These reinforcement bars are crucial for reinforcing concrete structures, providing strength and stability. However, the installation of rebars can be time-consuming, as they need to be accurately placed and secured before concrete can be poured. Delays in rebar installation can directly affect the progress of the construction project, potentially extending the timeline. Conversely, efficient and timely installation of rebars can expedite the construction process, ensuring smooth progress and adherence to the timeline.

- Q: How do steel rebars prevent concrete structures from collapsing?

- Reinforcement and strength are provided to concrete structures by steel rebars, which prevent their collapse. Concrete is capable of withstanding forces that compress or squeeze it, making it a strong material. However, it is not able to withstand forces that pull it apart, resulting in weakness in tension. When subjected to tension, concrete may crack and ultimately fail. To counteract these tensile forces and offer additional strength, reinforcement bars, also known as steel rebars, are typically embedded within concrete structures. These rebars are made of high-strength steel and are strategically placed to resist the pulling forces. When external forces, such as wind or seismic activity, impact a concrete structure, the rebars assist in distributing the load and resisting tension. As the concrete attempts to separate, the rebars hold it together, preventing the propagation of cracks and maintaining the structure's integrity. Additionally, the rebars enhance the overall durability and lifespan of the concrete structure. By reinforcing the concrete, they mitigate the effects of shrinkage and thermal expansion, which can lead to cracks over time. Consequently, a more stable and resilient structure is achieved, capable of withstanding various environmental and structural stresses. In conclusion, steel rebars are crucial in averting the collapse of concrete structures, as they provide the necessary reinforcement and strength to resist tension. They elevate the structural integrity, durability, and safety of concrete structures, ensuring their ability to withstand demands and fulfill their intended purpose for extended periods.

- Q: How do steel rebars affect the constructability of projects in environmentally sensitive areas?

- Projects in environmentally sensitive areas can be influenced both positively and negatively by the use of steel rebars. On the positive side, steel rebars are widely utilized in construction due to their strength and durability. They enhance the safety and stability of buildings and infrastructure, which is crucial in areas prone to high wind or seismic activity. By enabling the construction of resilient foundations and reinforcements, steel rebars reduce the risk of environmental damage. Additionally, the sustainability of projects in environmentally sensitive areas can be enhanced through the use of steel rebars. These rebars are highly recyclable, reducing the need for new raw materials and minimizing the environmental impact of resource extraction and processing. Incorporating steel rebars into construction projects can effectively reduce the carbon footprint, aligning with environmental conservation goals. However, there are also negative implications associated with steel rebars in environmentally sensitive areas. The production of steel emits greenhouse gases, contributing to climate change, which can harm fragile ecosystems and vulnerable species. Furthermore, the extraction of iron ore for steel production can lead to habitat destruction and deforestation, further impacting the environment. The transportation of steel rebars to construction sites in environmentally sensitive areas can also present challenges. It often requires the use of heavy machinery and vehicles, which if not properly managed, can cause soil compaction and erosion. This disturbance can disrupt natural habitats and affect the water quality of nearby rivers and streams. In conclusion, while steel rebars offer numerous benefits to projects in environmentally sensitive areas, they also present environmental challenges. It is crucial for construction companies and project stakeholders to carefully consider the sourcing, production, and transportation of steel rebars. Exploring alternative construction materials and techniques with lesser impact on the environment, as well as adopting sustainable practices like recycling steel rebars and reducing carbon emissions, can improve the constructability of projects in environmentally sensitive areas while mitigating their potential negative effects on the environment.

- Q: Can steel rebars be used in the construction of data centers and server rooms?

- Yes, steel rebars can be used in the construction of data centers and server rooms. Steel rebars provide structural reinforcement and can be used in the construction of walls, columns, and foundations. They help to enhance the overall strength and durability of the building, ensuring the safety and stability of the data center or server room infrastructure.

- Q: What is the effect of impurities on the corrosion resistance of steel rebars?

- Impurities in steel rebars can have a negative impact on their corrosion resistance. These impurities, such as sulfur, phosphorus, and certain non-metallic inclusions, can promote the formation of localized corrosion sites and accelerate the corrosion process. Additionally, impurities can weaken the protective oxide layer on the surface of the steel, making it more susceptible to corrosion. Therefore, minimizing impurities in steel rebars is crucial to ensure their long-term corrosion resistance and structural integrity.

- Q: Can steel rebars be used in the construction of railway or subway systems?

- Yes, steel rebars can be used in the construction of railway or subway systems. Steel rebars provide structural reinforcement and strength to the concrete structures used in railway or subway construction, making them essential for ensuring the safety and longevity of these transportation systems.

- Q: Can steel rebars be used in structures with aggressive chemical exposure?

- When working with structures that are exposed to aggressive chemicals, it is crucial to take precautions to prevent the corrosion of steel rebars. Over time, the corrosion weakens the structure. To minimize this risk, it is possible to apply corrosion-resistant coatings or materials to the rebars. These coatings create a barrier between the rebars and the aggressive chemicals, reducing the likelihood of corrosion by preventing direct contact. Moreover, it is necessary to regularly inspect and properly maintain the rebars to detect any signs of corrosion and take appropriate action. By implementing these protective measures, steel rebars can be safely utilized in structures exposed to aggressive chemicals.

- Q: How are steel rebars inspected for quality control?

- Steel rebars are inspected for quality control through various methods such as visual inspection, dimensional checks, and non-destructive testing techniques like ultrasonic testing and magnetic particle inspection. These inspections ensure that the rebars meet the required specifications, such as proper size, shape, and absence of defects, ensuring their quality and suitability for use in construction projects.

Send your message to us

Hot Rolled GB Standard Deformed Steel Rebars for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords