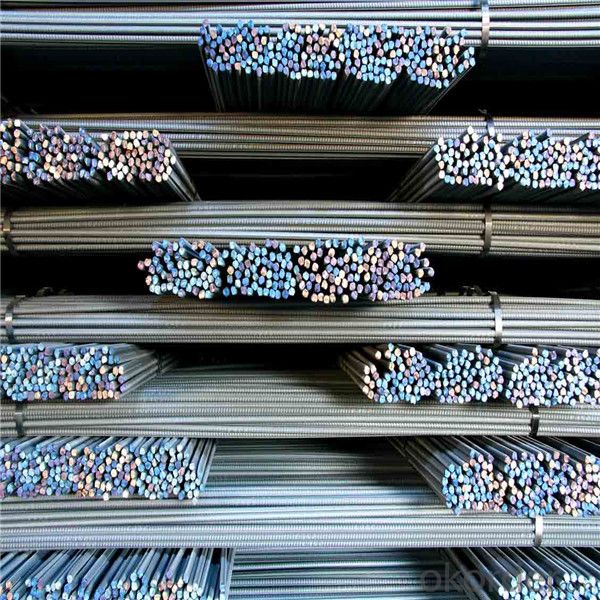

Deformed steel iron rods in different diameter

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 128362 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Our Advantage:

High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What are the safety precautions while handling steel rebars?

- When handling steel rebars, it is important to follow a few safety precautions. Firstly, always wear protective clothing such as gloves, safety glasses, and steel-toed boots to prevent injuries. It is crucial to lift and carry rebars properly, using proper lifting techniques and avoiding strain on your back. Additionally, be cautious of the sharp edges and points of the rebars to prevent cuts or punctures. Lastly, always store and stack rebars in a safe and organized manner to avoid accidents or tripping hazards.

- Q: Can steel rebars be used in structures with heavy snow loads?

- Indeed, structures burdened with heavy snow loads can incorporate steel rebars. These rebars are commonly employed in construction to fortify concrete structures and augment their strength. When designing structures in regions prone to heavy snowfall, engineers carefully consider the weight of the snow and ensure that the structure is equipped to bear the additional load. Steel rebars possess the strength necessary to endure substantial loads, allowing them to reinforce the concrete within a structure and enhance its resistance against snow-induced forces. Furthermore, steel rebars aid in distributing the load evenly throughout the structure, mitigating the risk of failure or collapse. Nevertheless, it is crucial to seek guidance from a structural engineer or a knowledgeable professional familiar with local building codes and regulations to guarantee the proper design and construction of the structure to meet the specific requirements for snow loads in the area.

- Q: Are steel rebars suitable for use in structures with high resistance to chemicals?

- No, steel rebars are not suitable for use in structures with high resistance to chemicals.

- Q: How are steel rebars anchored in concrete foundations?

- Steel rebars are anchored in concrete foundations by using various methods such as overlapping rebars, hooking them into the concrete, or using mechanical devices like rebar couplers. These anchoring techniques ensure that the rebars are securely embedded in the concrete, providing strength and stability to the foundation structure.

- Q: Can steel rebars be used in bridge construction projects?

- Yes, steel rebars can be used in bridge construction projects. Steel rebars are commonly used as reinforcement in concrete structures, including bridges. They provide strength and stability to the bridge, enhancing its load-bearing capacity and resistance to various forces such as tension, compression, and bending. Steel rebars are highly durable and can withstand harsh environmental conditions, making them an ideal choice for bridge construction where longevity and structural integrity are crucial. Additionally, steel rebars can be easily shaped and bent to suit the specific design requirements of the bridge, allowing for flexible and efficient construction. Overall, steel rebars are widely accepted and commonly used in bridge construction projects due to their excellent mechanical properties and reliability.

- Q: How do steel rebars contribute to the overall sustainability of concrete structures?

- Steel rebars contribute to the overall sustainability of concrete structures in several ways. Firstly, steel rebars enhance the durability and lifespan of concrete structures. By reinforcing the concrete, rebars provide added strength and prevent cracking or structural failures, thereby extending the life of the structure. This reduces the need for frequent repairs or replacements, saving resources and minimizing the environmental impact of construction activities. Moreover, steel rebars are 100% recyclable. At the end of a structure's life cycle, the rebars can be easily removed and recycled, reducing the demand for new raw materials and minimizing waste. This not only conserves natural resources but also reduces greenhouse gas emissions associated with the extraction and production of virgin steel. Additionally, incorporating steel rebars into concrete structures allows for the use of thinner concrete sections. By using less concrete, there is a reduced demand for cement, which is a major contributor to carbon dioxide emissions during its production. Therefore, the use of steel rebars helps to lower the overall carbon footprint of concrete structures. Furthermore, steel rebars can be designed to resist corrosion, which is a common issue in concrete structures exposed to harsh environments or in coastal areas. By providing protection against corrosion, the rebars increase the service life of the structure, reducing the need for maintenance and repairs. This not only saves costs but also reduces the environmental impact associated with maintenance activities. Overall, steel rebars play a crucial role in enhancing the sustainability of concrete structures by improving their durability, enabling recycling, reducing material consumption, and minimizing maintenance requirements. By incorporating steel rebars into concrete construction, we can create long-lasting, environmentally-friendly structures that contribute to a more sustainable built environment.

- Q: How do steel rebars perform in corrosive environments?

- Steel rebars perform well in corrosive environments, thanks to their inherent resistance to corrosion. The presence of protective oxide layers on the surface of steel rebars helps prevent the penetration of corrosive elements such as moisture and chemicals. Additionally, the use of corrosion-resistant coatings or stainless steel rebars can further enhance their performance in highly corrosive environments.

- Q: Can steel rebars be used in renovation or retrofitting projects?

- Yes, steel rebars can be used in renovation or retrofitting projects. Steel rebars are commonly used in construction projects to reinforce concrete structures, providing strength and durability. In renovation or retrofitting projects, where existing structures need to be strengthened or modified, steel rebars can be utilized to enhance the structural integrity and ensure the safety of the building.

- Q: Are steel rebars suitable for use in industrial facilities?

- Steel rebars are an excellent choice for industrial facilities due to their high suitability. They are commonly employed in construction projects to reinforce concrete structures, and their strength and robustness make them ideal for environments that experience heavy loads and high stress. By utilizing steel rebars, the structural integrity and load-bearing capacity of the facility are enhanced, ensuring its ability to withstand the demands of industrial operations. Moreover, steel rebars demonstrate exceptional resistance to corrosion, which is particularly important in industrial settings where exposure to moisture, chemicals, and other corrosive substances is prevalent. In conclusion, steel rebars offer the necessary durability, strength, and corrosion resistance required for reinforcing concrete structures in industrial facilities, making them a suitable choice.

- Q: How are steel rebars manufactured and processed?

- Steel rebars are manufactured and processed through a series of steps. Firstly, the raw materials like steel billets or scrap metal are melted in a furnace to create molten steel. This molten steel is then poured into molds of desired shapes and sizes to form billets. These billets are further processed through a rolling mill, where they are heated and passed through a series of rollers to shape them into long, thin bars. The bars are then cooled, straightened, and cut into desired lengths. To enhance their strength, rebars are often subjected to heat treatment or alloying processes. Finally, they undergo surface treatment, such as corrosion-resistant coatings, to protect against rusting. The finished steel rebars are then ready for use in construction and reinforcing concrete structures.

Send your message to us

Deformed steel iron rods in different diameter

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 128362 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords