STEEL COIL SGCC Z80

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prime Galvanized steel coil

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity

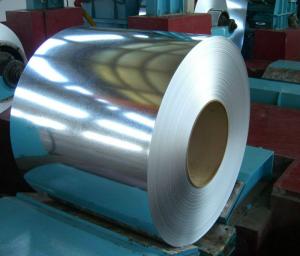

Hot dip galvanized steel coil

Technical Standard:JIS 3302 / ASTM A653 / EN10143/ GB/T 2518

Grade:DX51D/ S250,280,320GD,SGCC,SGHC,SGH340,SGH400,SGH440,G450,G550

Types:Commercial / Drawing / Deep Drawing / Structural quality

Width: 900mm/1000mm/1219mm/1200mm/1220mm/1250mm

Thickness: 0.2mm~4.0mm

Type of coating: galvanized

Zinc coating: Z40-275g/m2,Z40-Z450g/m2

Surface treatment:zero spangle / regular spangle/ big spangle

ID coil: 508mm or 610mm

Coil weight: 3-10/MT per coil

Package:Properly packed for ocean freight exportation in 20''container

Application::home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

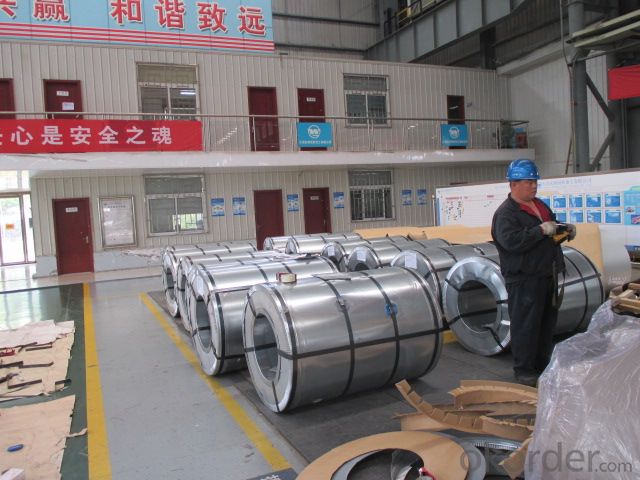

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of product

- Q: How do steel coils contribute to the renewable energy equipment industry?

- Steel coils play a crucial role in the renewable energy equipment industry by being a key component in the manufacturing of various renewable energy technologies. One of the primary applications of steel coils is in the production of wind turbines. The tower, nacelle, and rotor blades of wind turbines all require steel coils for their construction. In the manufacturing of wind turbine towers, steel coils are used to fabricate the structural components that provide stability and support to the turbine. These coils are typically rolled and welded together to form the tower, ensuring its strength and durability to withstand the forces exerted by the wind. Additionally, steel coils are also used to produce the nacelle, which houses the generator and other essential components of the wind turbine. Moreover, steel coils are used in the production of rotor blades for wind turbines. These blades are responsible for capturing the wind and converting it into rotational energy. Steel coils are used to create the internal structure of the blades, providing the necessary strength and rigidity to withstand the aerodynamic forces. The coils are often combined with composite materials to optimize the performance and efficiency of the blades. Apart from wind turbines, steel coils are also used in other renewable energy technologies such as solar panels. In the manufacturing of solar panels, steel coils are used to create the frames and supporting structures that hold the photovoltaic cells in place. These frames ensure the stability and longevity of the solar panels, allowing them to efficiently capture sunlight and convert it into electricity. Overall, steel coils are vital in the renewable energy equipment industry as they provide the necessary strength, durability, and structural support to various renewable energy technologies. By enabling the production of wind turbines, solar panels, and other renewable energy equipment, steel coils contribute to the expansion and development of the renewable energy sector, thereby advancing the global transition towards cleaner and more sustainable sources of energy.

- Q: What are the different types of steel coil cutting methods?

- There are several different types of steel coil cutting methods, including slitting, shearing, and laser cutting. Slitting involves cutting the coil into narrower strips using rotating circular knives. Shearing is the process of cutting the coil using straight blades to create straight edges. Laser cutting uses a focused laser beam to melt and vaporize the steel, resulting in a precise and clean cut.

- Q: What is the role of steel coils in the production of industrial machinery?

- Steel coils play a crucial role in the production of industrial machinery as they serve as the raw material for various components and parts. The coils are often used to fabricate structural frames, gears, shafts, and other essential elements that provide strength, durability, and stability to the machinery. The versatility and strength of steel make it an ideal material for withstanding the rigorous demands of industrial applications, ensuring the reliability and performance of the machinery.

- Q: How are steel coils used in the manufacturing of automotive body panels?

- Steel coils are used in the manufacturing of automotive body panels by being formed and shaped into the desired panel shape through processes such as stamping, pressing, and roll forming. These coils provide the necessary strength and durability required for automotive body panels, ensuring the structural integrity and safety of the vehicle.

- Q: which metals have a higher density than steel? and how does the density compare to steel( example: tungsten carbide is 2x [i think] more dense than steel.)

- This Site Might Help You. RE: what metals are more dense than steel? which metals have a higher density than steel? and how does the density compare to steel( example: tungsten carbide is 2x [i think] more dense than steel.)

- Q: My company want to welding stainless steel, do not know to use what welding machine?

- MIG and TIG welding will produce a better looking weld with little slag left on the weld. They also make coated rods that can be used with stainless, that will leave a slag behind just like carbon steel welding. Any of these can be used. Specifics of which materials and method should be employed depend on the specifics of the materials used, what joint type is being made, what position the weld must be made in, etc.

- Q: I'm trying to put together a small structure using galvanized steel electrical conduit (3/4) and I can't seem to find a T-junction conduit coupler anywhere. I'm wondering if I could weld the tubing together, but I'm not sure if I can weld galvanized steel. Also, if I can weld them, is there any special technique that I need to use outside of regular acetelene/oxygen torch and solder?

- This Site Might Help You. RE: Can you weld galvanized steel? I'm trying to put together a small structure using galvanized steel electrical conduit (3/4) and I can't seem to find a T-junction conduit coupler anywhere. I'm wondering if I could weld the tubing together, but I'm not sure if I can weld galvanized steel. Also, if I can...

- Q: hey therejust wondering about changing nylon strings to steel strings...i have an acoustic guitar and it has nylon strings, but i was thinking about switching to steel strings, as i think it sounds better.this might sound really stupid... but is that possible? i mean they call it a steel stringed GUITAR and nylon stringed GUITAR, so if i wanted to switch would i have to get a whole new guitar? please help, im reaaally confused!thanks

- I asked my guitar teach this and the thing with changing from nylon strings to steel strings is that the nylon tuning forks are accustomed to nylon and tend to slip. But, in say that you can do it, but, you would have to wait awhile for them to start sticking. If i have helped the Your welcome and Thanks! =]

- Q: How are steel coils used in the manufacturing industry?

- Steel coils are used in the manufacturing industry for a variety of purposes, including the production of various steel products such as automotive parts, construction materials, household appliances, and machinery components. These coils are often processed and formed into desired shapes through techniques like cutting, bending, and welding to create finished products that are durable, strong, and suitable for various applications in different sectors.

- Q: I know that steel wool is coated with... something... that protects it from rusting. I need to know what that is, and how to get it off.

- spun steel fibers have a microscopic coating of oil to prevent them from rusting. Rusting steel wool wouldn't sell very well. I would think that removing this oil could be accomplished with any good degreaser, like brake cleaner or the like. However, I've never tried this before. In science class they perform experiments by removing the oil with vinegar. After wringing out the steel wool pad, it is wrapped around a thermometer and placed in a sealed jar. After a few minutes the temperature rises because of the chemical reaction that takes place when four atoms of iron react with three atoms of oxygen and create two atoms of iron oxide - RUST! You can unwittingly recreate this experiment by using steel wool in the process of removing one or more layers of finish from a piece of furniture Hope this helps

Send your message to us

STEEL COIL SGCC Z80

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords