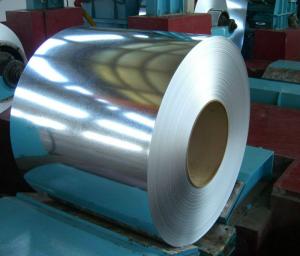

cold rolled steel coils for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SPCC cold rolled steel coil

1) Product Name: Cold rolled Steel Coil/sheet/strip

2) Thickness: 0.4mm-3.0mm

3) Width: 600mm-2000mm

4) Length: As requested

5) Width tolerance: different as per different width

6) Thickness tolerance: different as per different thickness

7) Weight: According to the different requirement

8) Packing: Mill standard export packing in bundles

9) Country of Origin : China

10)Standard: AISI, ASTM29, DIN16723, EN10130, JIS, GB

11)Grade: SPCC, SPCD, SPCE, SPCH, ST12-15, DC01-06, Q195A-Q235A

12)Width: 600-2000mm (general width: 1000mm, 1250mm, 1500mm)

13)Application:

1.For the further producing of hot dip galvanized steel products

2.Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

14)Packing: Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from

15)Payment term: L/C, T/T

16)Delivery date: 15-30 days

17)General Specification:

Classification | Designation | Characteristics | Main applications |

Commercial quality | SPCC SPCCT | Commercial quality suitable for bending fabrication and simple forming; this is thetype in greatest demand. | Refrigerators, cabinets, power distribution baords and drums. |

Drawing quality | SPCD | Drawing quality second only tothat of SPCEN. Excellent uniformity. | Automobile floor and roof panels. |

Deep-drawing quality | SPCE SPCF | Deep-drawing quality.With metallurgically controlled grain size, it retains its beautiful finish even after being deep-drawn. | Automobile fenders and quarter panels |

Extra deep-drawing quality | SPCG | Extra-low-carbon steel sheets with highest workability | Automobile internal panels and deep-drawn parts |

- Q: What are the different coil packaging materials used for steel coils?

- Different materials are used for packaging steel coils, each with its own unique properties and benefits. Some of the most commonly used materials are as follows: 1. Stretch film is a flexible material that tightly wraps around the coil, providing protection against dust, moisture, and scratches. 2. Steel strapping is a strong and durable option that ensures the coils remain tightly bound during transportation or storage, thanks to its high tensile strength and resistance to breakage. 3. Plastic strapping, on the other hand, is a lightweight and cost-effective alternative to steel strapping. It offers good shock absorption and is resistant to rust and corrosion, making it suitable for smaller or lighter steel coils. 4. Paperboard is an environmentally friendly packaging material that provides a protective layer against dust and minor impacts. It also allows for slight breathability to prevent moisture buildup. 5. Wooden crates are commonly used for large or heavy steel coils, as they offer sturdy support and protection during handling, transportation, or storage. 6. Corrugated cardboard is a versatile and lightweight material suitable for smaller steel coils. It provides cushioning and protection against minor impacts, and it is easily recyclable. The choice of packaging material for steel coils depends on factors such as coil size and weight, transportation requirements, and the desired level of protection. Each material has its own advantages and should be selected based on the specific needs of the steel coil packaging.

- Q: i wanna buy a sharp carbon steel sword the swords i want are a 200 layer carbon steel katana or a hand forged high carbon steel katanna or a hand sharpened sword which one would be sharper/stronger

- Carbon steel is a generic term. There are many different grades of carbon steel consisting of several different components of various amounts, and there are different types of treatment the steel can go through that changes it's quality. Carbon steel swords are a step up from the crappy stainless steel swords, and other alloys. Sword quality completely depends on the smith. 200 layers doesn't mean there won't be any imperfections. Sword makers make mistakes, especially the lesser experienced ones. Look into the maker(s) of the sword you're looking to buy. Find information on them before deciding. Carbon steel is the steel to have, but that doesn't exclude good or bad quality. Sharpness will depend on the the steel and the smith.

- Q: What are the challenges in coil leveling for coated steel?

- Coil leveling for coated steel presents several challenges that need to be addressed in order to achieve high-quality, flat, and smooth coils. Firstly, one of the main challenges is the potential for coating damage during the leveling process. Coated steel coils are typically coated with materials such as zinc or paint, which can be easily scratched or marred if not handled properly. The leveling process involves passing the coil through a set of leveling rolls, which can potentially cause friction, abrasion, or other mechanical damage to the coating. Therefore, it is crucial to carefully control the speed, pressure, and alignment of the leveling rolls to minimize coating damage. Secondly, the thickness variation across the coil presents a significant challenge. Coated steel coils often have thickness variations due to inherent material properties or production processes. These variations can result in uneven leveling and can lead to coils with waviness or uneven flatness. Achieving uniform leveling across the entire coil surface is essential to ensure consistent quality and appearance of the final product. Another challenge in coil leveling for coated steel is the possibility of coil shape distortion. Coating processes can introduce stresses into the steel, which can cause the coil to warp or distort during the leveling process. This distortion can result in coils with uneven edges or inconsistent flatness. Proper control of the leveling process parameters, such as the number of leveling passes and the tension applied to the coil, is necessary to minimize shape distortion. Additionally, the coil leveling process can generate internal stresses in the steel itself, particularly in coated steels that have been cold-rolled or heat-treated. These internal stresses can cause coil spring-back, where the coil tries to return to its original shape after leveling. Spring-back can result in coils with unwanted curvature or uneven flatness. Effective strategies, such as stress relief annealing or using counteracting leveling techniques, are essential to minimize spring-back and achieve the desired flatness. Finally, the handling and storage of coated steel coils present challenges in maintaining the quality of the leveled coils. Coated steel coils are sensitive to environmental conditions such as humidity, temperature, and exposure to corrosive agents. Proper storage and handling practices are crucial to prevent coating damage, rust, or other forms of deterioration that can occur during transportation or storage. In summary, the challenges in coil leveling for coated steel include minimizing coating damage, addressing thickness variation, controlling shape distortion and spring-back, and ensuring proper handling and storage. Overcoming these challenges requires precise control of process parameters, the use of appropriate leveling techniques, and adherence to strict quality control measures throughout the entire process.

- Q: How do steel coils contribute to the manufacturing of construction materials?

- Steel coils play a crucial role in the manufacturing of construction materials by providing a versatile and reliable source of raw material. These coils are manufactured from high-quality steel and are typically used as a primary input in various construction processes. One of the main contributions of steel coils in construction material manufacturing is their ability to be shaped and formed into different products. These coils can be easily cut, bent, and molded to create a wide range of construction materials such as beams, pipes, and sheets. This versatility allows manufacturers to produce customized construction components that meet specific project requirements. Furthermore, steel coils provide strength and durability to construction materials. Steel is known for its exceptional tensile strength, which makes it an ideal choice for load-bearing structures and components. By using steel coils, manufacturers can produce construction materials that can withstand heavy loads, extreme weather conditions, and other environmental factors, ensuring the longevity and safety of the final construction product. In addition, steel coils offer consistency in quality and performance. The manufacturing process of steel coils involves stringent quality control measures, ensuring that the final product meets the required specifications. This consistency in quality gives construction material manufacturers the confidence to produce reliable and high-performance products consistently. Steel coils also contribute to the efficiency of construction material manufacturing. The availability of steel coils in large quantities and standardized dimensions allows for streamlined production processes. Manufacturers can optimize their operations by utilizing automated machinery and processes, reducing production time and costs, and increasing overall efficiency. Overall, steel coils are an essential component in the manufacturing of construction materials. Their versatility, strength, consistency, and efficiency make them a preferred choice for construction material manufacturers. By using steel coils, manufacturers can create high-quality and reliable construction materials that contribute to the safety, durability, and aesthetics of various construction projects.

- Q: Steel coil from vertical to horizontal, what sling needs?

- The sling has little effect, but it is easy to damage the surface of rolled steel.

- Q: Can steel coils be coated with noise-reducing materials?

- Yes, steel coils can be coated with noise-reducing materials.

- Q: How does stainless steel soap work? I have read the detailed explanation on Wikipedia, but their desciption seems skeptical on the actual chemical process that may take place from using such an item. Is there an actual scientific explanation to how stainless steel soap is able to clean your hands, when it is only a piece of metal?

- Many metals have germicidal qualities. Silver is the strongest germicide of the metals, but a sterling silver bar of soap would be expensive and it would tarnish. The tarnish would actually not affect the silver's ability to kill bacteria, but it would look bad and the tarnish would turn your hands black, so people wouldn't want to use it. Many people even take silver internally in the form of Colloidal Silver, but Colloidal Silver is very controversial. Yes, it kills many bacteria, but it can also cause a person's skin to permanently turn blue...a condition called Argyria. Brass actually is a better germicide than stainless steel...but again this is a cosmetic problem. Brass tarnishes, so people wouldn't want to use it. Stainless steel is actually a very weak germicide, but even steel has some ability to kill germs. Stainless steel also removes fish odor. My son has a stainless steel bar that he takes along when he fishes to remove the fish smell from his hands. There's nothing magical about the bar...a stainless steel spatula would would just as well, but the bar is more convenient to carry. I'm not sure if this is scientific enough or not. -

- Q: How do steel coils contribute to the sustainability of construction projects?

- There are several ways in which steel coils contribute to the sustainability of construction projects. First and foremost, steel is a highly durable and long-lasting material. Manufactured to withstand extreme weather conditions, corrosion, and other external factors, steel coils are ideal for construction projects that require strength and longevity. This durability reduces the need for frequent repairs and replacements, resulting in minimized waste and resource consumption over time. Moreover, steel coils are recyclable. Once their lifespan in a construction project comes to an end, steel coils can be easily and efficiently recycled. This recycling process requires less energy compared to the production of new steel, leading to reduced carbon emissions and environmental impact. Furthermore, the recycled steel can be utilized in various industries, including construction, thereby promoting sustainability and resource conservation. Additionally, steel coils contribute to the sustainability of construction projects by offering design flexibility. Being a versatile material, steel can be easily shaped, cut, and molded into different forms and sizes. This allows for efficient construction practices, reducing material wastage and optimizing resource utilization. Furthermore, the lightweight nature of steel coils enables convenient transportation and installation, further decreasing fuel consumption and associated greenhouse gas emissions. Lastly, steel coils contribute to the sustainability of construction projects through their energy efficiency. Being an excellent conductor of heat and electricity, steel is ideal for energy-efficient buildings. By incorporating steel coils into the construction of walls, roofs, and other components, buildings can be effectively insulated, resulting in reduced energy consumption for heating and cooling. Consequently, occupants benefit from lower energy bills, while the overall carbon footprint of the construction project is reduced. In conclusion, steel coils contribute to the sustainability of construction projects through their durability, recyclability, design flexibility, and energy efficiency. By utilizing steel coils, construction projects can minimize waste, conserve resources, reduce environmental impact, and optimize energy consumption, thereby promoting a more sustainable and eco-friendly approach to construction.

- Q: How are steel coils used in the manufacturing of transmission shafts?

- Steel coils are used in the manufacturing of transmission shafts as they provide the raw material required for shaping and forming the shaft. The steel coils are typically cut into specific lengths and then undergo various processes such as heat treatment, machining, and forging to shape them into transmission shafts, which are crucial components in the transmission system of vehicles and machinery.

- Q: Are Steel buildings Fire Resistant, just want to know as I am going to owe it . Suggestions required…………..

- Steel okorder

Send your message to us

cold rolled steel coils for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords