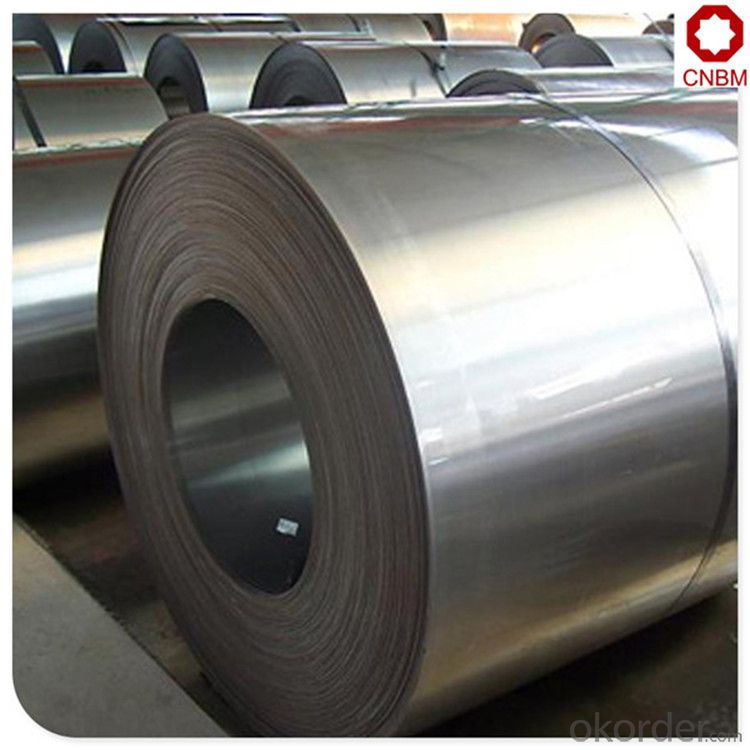

Steel coil packing well with zinc coating hot dipped

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 26 m.t.

- Supply Capability:

- 35893 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development

- Q: All of my friends say that if a car made of mostly carbon fiber would crash into a full steel car, or vice versa, the steel car would be DESTROYED and the carbon fiber would drive away, if not, easily repairable.

- Depends on the design/construction.

- Q: How long do steel coils typically last?

- Steel coils typically last for several decades, with an average lifespan ranging from 20 to 30 years. However, the actual durability and lifespan depend on various factors, such as the quality of the steel, the environment it is exposed to, how well it is maintained, and the frequency of use.

- Q: How are steel coils inspected for elongation using elongation testers?

- Steel coils are inspected for elongation using elongation testers by first selecting a representative sample from the coil. This sample is then mounted onto the tester, which applies a controlled force to stretch the steel. The elongation tester measures the change in length of the sample as it is stretched, allowing the calculation of the elongation percentage. This data is crucial for evaluating the steel's ductility and mechanical properties, ensuring it meets quality standards and can withstand various applications.

- Q: i am looking for an exact process of how to forge damascus steel.any tips or pointers and web sites or tutoreals will be helpfull.

- hand made folding knife English tip, blade of Damascus metallic sort Rose, 2,5mm thickness, no liners, teja spring embellished by using metallic report and billet surrounded of chrome metallic. A Damascus blade knife is characterised by using a wavy, mottled visual allure on the blade that’s led to by using the approach used to shape the metallic. the technique of transforming into Damascus metallic is derived from a centuries-previous forging technique used to create blades that grew to become very just about mythical of their attractiveness for power and sharpness it exchange into reported a Damascus knife ought to shrink with the aid of a rifle barrel to boot as with the aid of a hair falling on the blade.

- Q: What are the different methods of leveling steel coils?

- There are several methods used to level steel coils, including roller leveling, stretcher leveling, and tension leveling. Roller leveling involves passing the coil through a series of rollers that gradually bend and flatten the steel to remove any curvature or unevenness. Stretcher leveling uses hydraulic or mechanical forces to stretch the steel in order to eliminate any residual stress and improve flatness. Tension leveling applies tension to the steel coil while it is being passed through a series of rolls, which helps to remove any waviness or shape defects. These methods are employed depending on the specific requirements and desired flatness of the steel coils.

- Q: How do steel coils contribute to the agricultural machinery industry?

- Steel coils are an essential component in the agricultural machinery industry due to their versatile and durable nature. They are used in various applications and play a crucial role in improving the efficiency and productivity of agricultural machinery. One of the primary ways steel coils contribute to the agricultural machinery industry is through their use in the manufacturing of equipment frames and structures. These frames provide the necessary strength and stability to withstand the demanding conditions of agricultural operations. Whether it is in tractors, harvesters, or tillers, steel coils are used to create sturdy and rigid frames that can handle heavy loads, vibrations, and impacts. Additionally, steel coils are used in the fabrication of components such as plow blades, cultivator tines, and seed drills. These components are crucial for soil preparation, seed planting, and crop maintenance. Steel coils provide the necessary strength and resistance to wear and tear, ensuring these components can withstand the rigors of agricultural operations and last for extended periods. Furthermore, steel coils are also used in the manufacturing of hydraulic systems and other moving parts in agricultural machinery. These systems are responsible for powering and controlling various functions, such as lifting, lowering, and steering. Steel coils provide the necessary strength and flexibility for these systems to function optimally, ensuring smooth and efficient operation of agricultural machinery. Moreover, steel coils contribute to the agricultural machinery industry by enhancing the safety and longevity of the equipment. Steel is known for its excellent resistance to corrosion, rust, and extreme weather conditions. By using steel coils in the construction of agricultural machinery, manufacturers can ensure that the equipment remains durable and reliable even in harsh environments, ultimately reducing maintenance costs and improving the overall lifespan of the machinery. In conclusion, steel coils are an indispensable component in the agricultural machinery industry. Their versatility, strength, and durability make them crucial for the manufacturing of equipment frames, components, hydraulic systems, and other moving parts. By utilizing steel coils, the agricultural machinery industry can produce robust and efficient equipment that can withstand demanding agricultural operations, improve productivity, enhance safety, and extend the lifespan of the machinery.

- Q: Can steel coils be stored in a humid environment?

- Steel coils can be stored in a humid environment, but it is not ideal. Humidity can cause steel coils to rust and corrode, leading to potential damage or degradation of the steel. It is recommended to store steel coils in a dry and well-ventilated area to protect them from the negative effects of humidity.

- Q: Can steel coils be used in the production of HVAC systems?

- Yes, steel coils can be used in the production of HVAC systems. Steel coils are often used in the manufacturing of HVAC equipment such as air conditioners, heat pumps, and furnaces. These coils are typically made from high-quality steel and are designed to efficiently transfer heat or cool air. The steel coils provide durability, strength, and corrosion resistance, making them suitable for HVAC system applications.

- Q: Are steel coils used in agricultural equipment manufacturing?

- Yes, steel coils are commonly used in agricultural equipment manufacturing. Steel coils are used to create various components such as frames, brackets, and supports, which are essential for the construction and durability of agricultural equipment. The strength and versatility of steel make it a preferred material choice for manufacturing agricultural machinery.

- Q: What are the common coil handling challenges?

- Common coil handling challenges include the risk of coil damage during handling and transportation, difficulties in aligning and positioning coils accurately, issues with coil slippage and instability, as well as the need for specialized equipment to safely and efficiently handle large and heavy coils. Additionally, managing coil edges and preventing injuries to workers are also common challenges faced in coil handling processes.

Send your message to us

Steel coil packing well with zinc coating hot dipped

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 26 m.t.

- Supply Capability:

- 35893 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords