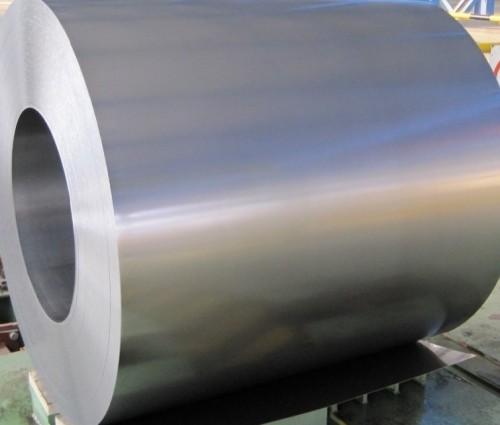

High-Zinc-coatingHot Dipped Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Hot Dip Galvanized Steel Coil

Steel Grade & Standard:EN10327 DX51D

Zinc Coating Mass:Z450

Spangle:Regular Spangle

Surface Treatment:Chromated,Unoiled,NonSkinpassed

SIZE (MM) (BMT) MOQ (MTS)

1.9*700*C 100

2.5*700*C 100

2.7*700*C 100

Coil ID:610mm

Coil Weight:3-5MT

Package Type:EYE TO SIDE

Thickness Tolerance:+/-0.12MM

Width Tolerance:0/+5mm

Zinc Coating Tolerance:0/+10gsm

VALIDITY: 3 WORKING DAYSPAYMENT: T/T WITH 30% DOWNPAYMENT AND BALANCE AGAINST INVOICE & PACKING LISTSHIPMENT: 45 DAYS FOR CARGO READINESS AND 15 DAYS FOR CATCHING THE RIGHT VESSEL

- Q: What are the common coil loading and unloading procedures?

- Common coil loading procedures involve using cranes or forklifts to lift and position coils onto trailers or flatbed trucks. The coils are typically secured using straps, chains, or coil racks to prevent shifting during transportation. During unloading, the same equipment is used to carefully lift and remove the coils from the truck, ensuring safety and stability throughout the process.

- Q: What is the width range of steel coils?

- The width range of steel coils can vary depending on the specific requirements, but it typically ranges from a few millimeters to several meters.

- Q: I have a new stainless steel trash compactor under a butcher block counter. We refinished the countertop, but unfortunately the person who did it wasn't careful with the orbital sander and sanded the top edge of the stainless steel compactor door, ruining the finish. The sander marks are not deep - just surface scratches - but they are unsightly. Is there any way to restore the finish to the stainless steel without having to buy a new door?

- Go over the entire surface with wet/dry sandpaper with the grain. Use wet with a little dish detergent. Remove the handles and name plates first. Start with 400, then 600, and then 800. Auto supply should sell the sandpaper. After final sanding, wax with carnuba wax and polish. Works on aluminum and real stainless not painted surfaces.

- Q: I want to buy steel. My problem is i purchase it from a middle man, so i need to know what MIld steel is. What it's real name or specifications is/are. I dont want to end up purchasing Black steel or other stuff i can sell or use...

- I am a Blacksmith,mild Steel is what I use every Day,I make Ornamental Ironworks,like Handrails,Gate,Candle holders,all kind of things,most things are made from mild Steel,even Buildings,Doors,and so on.No risk of buying it.Special Steel is just for Special Applications.

- Q: How are steel coils used in the production of steel cables?

- Steel coils are used in the production of steel cables by being uncoiled and straightened, then fed into a machine that twists and braids them together to create the cable.

- Q: I was wondering because i just watched an episode of build it bigger on the discovery channel about the uss George bush, and when they were discribing it they said it was 500 tons of steel and 47,000 tons of aluminum. this kinda struck me as odd because i thought that it was mostly made of steel. and i would think that even if it was mostly aluminum, that the hull would be steel. and i think the hull would weigh more than 500 tons.

- STEEL okorder /

- Q: Perform three sets of 15 repetitions several times a week and you will soon have buns of steel.

- Means you will have a nice booty, but the true question is... What does Buns of Steel mean by several times and SOON? Good luck.

- Q: What are the major challenges faced by steel coil manufacturers?

- The major challenges faced by steel coil manufacturers can be categorized into several key areas. 1. Raw Material Costs: One of the primary challenges is the fluctuating prices of raw materials, such as iron ore and coal, which are essential for steel production. Manufacturers have to constantly monitor and adjust their pricing strategies to mitigate the impact of these fluctuations and maintain profitability. 2. Global Competition: Steel coil manufacturers face intense competition from both domestic and international players. Globalization has led to an increase in the availability of steel coils from various regions, making it crucial for manufacturers to differentiate themselves through quality, pricing, and customer service to remain competitive. 3. Technological Advancements: The steel industry is constantly evolving and adopting new technologies. Manufacturers need to invest in modern equipment and machinery to improve efficiency, reduce costs, and meet stringent quality standards. Keeping up with technological advancements can be challenging, especially for smaller or less financially stable manufacturers. 4. Environmental Regulations: Steel production is a resource-intensive process that can have a significant impact on the environment. Governments worldwide are imposing stricter regulations on emissions, waste disposal, and energy consumption, which poses a challenge for steel coil manufacturers. Compliance with these regulations requires significant investments in pollution control technologies and sustainable practices. 5. Skilled Workforce: The steel industry requires a skilled workforce with expertise in various areas such as metallurgy, engineering, and operations. However, attracting and retaining skilled employees can be challenging, as the industry faces a shortage of qualified personnel. Manufacturers need to invest in training and development programs to ensure a competent workforce and maintain operational excellence. 6. Economic Volatility: Steel coil manufacturers are highly sensitive to economic fluctuations. During periods of economic downturns, demand for steel products decreases, leading to excess capacity and lower profit margins. On the other hand, during economic booms, manufacturers may face challenges in meeting increased demand and ensuring timely delivery. 7. Transportation and Logistics: Steel coils are bulky and heavy, making transportation and logistics a significant challenge for manufacturers. Optimizing supply chain management, coordinating with freight partners, and ensuring timely delivery of products to customers across various geographies can be complex and costly. In conclusion, steel coil manufacturers face several challenges, including raw material costs, global competition, technological advancements, environmental regulations, skilled workforce requirements, economic volatility, and transportation logistics. Overcoming these challenges requires proactive strategies, continuous improvement, and a focus on innovation to remain competitive in the industry.

- Q: The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- If it does not could desire to hold an part o.k. then 440 stainless could be your appropriate guess. I want severe carbon steel. yet they require alot of cleansing and oiling or they're going to rust.

- Q: 1943 steel pennies

- if you collect coins, you need to learn that they must never be cleaned. cleaning, while it might make them look pretty, ruins their value as a collectable. ask your coin dealer.

Send your message to us

High-Zinc-coatingHot Dipped Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords