Color coated galvanized rolled steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Brief Introduction

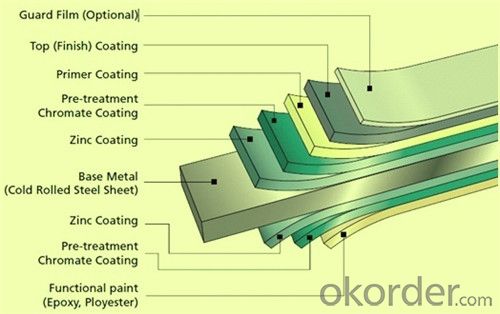

1. Prepainted Galvanized Steel Coil Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for Prepainted Galvanized Steel Coil is HDGI steel. The finish coats of Prepainted Galvanized Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Prepainted Galvanized Steel Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Prepainted Galvanized Steel Coil Coil can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Specification

1. Thickness: 0.3-0.8mm

2. Width: 914-1250mm

3. Inner Diameter: 508mm

4. Weight of Steel Coil: 3-15MT

5. Available Dipped Layer: 50-150g/m2

6. Surface Texture: Normal Coated

7. Type of coating structure: 2/1 Coat the top surface of the steel sheet twice, coat the bottom surface once, and bake the sheet twice.

8. Front Side Paint Thickness: 15-25μm (bottom paint + top paint)

9. Back Side Paint Thickness: 5-10μm

Common performance of front coating

1. Thickness: ≥20μm

2. Pencil Hardness: 2H

3. 60° specular glossiness of coating: >60

4. 180°bend: ≤3T

5. Impact: ≥9J

6. Salt Fog Resistant: ≥500h

7. Color difference: <3ΔE

Application

1. Construction: (Outside) workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door

(Inside) door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter

2. Electrical appliance: refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker

3. Furniture: central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf

4. Carrying trade: exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board

5. Others: writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment

- Q: Hi I was thinking about buying this knife, but i wasn't sure if it was good because it's stainless steel.

- This isn't really a question for this section, but I'm still happy to help out since I'm a big cutlery nerd as well. One thing to look out for when buying a knife is a lack of specifics on what steel is being used. High Carbon Stainless Steel doesn't tell you what the steel is, just what it MIGHT be. Chances are it's something along the lines of 420HC or 440A, both of which are softer steels. They aren't the worst steels around, but they are very quick to dull. You'd be better off looking at the Balisongs of Benchmade. They'll cost more, but you'll know that you're getting something made with quality materials and that won't break on you. And if it does break for some odd reason, Benchmade's warranty and customer service are both fantastic. Although if a more questionable knife is okay with you as long as the price isn't too high, then at least 420HC and 440A aren't too brittle and will take a decent edge even though they'll dull quickly. As for whether stainless steel is good for a knife or not, that depends on the type of stainless steel and what you're going to use the knife for. Many stainless steels are more brittle than a carbon steel, so high carbon stainless steels are a bit more likely to rust but a little tougher as well. In a butterfly knife, a steel like that is a good way to go, although the steels used by Benchmade, as I mentioned, are of a much better quality.

- Q: i cant find this stuff about steel:conductivitystrengthcorrosion resistancecommon applicationsif you know of any interesting facts, i could use those 2!thanx!

- The strength and corrosion resistance depends on the mix. Pure steel is pure iron plus 6% pure carbon. It is the carbon molecules that give it a tough crystallized strength. Pure iron is wrought iron and you can bend that with your hands. Strength also depends on the shape of the beam the most common steel beam is the W flange more commonly called the I beam. That is because the strength of the ‘I’ beam is just a little bit less than if the entire I beam was filled in; however the weight and material savings is huge. Steel itself has no corrosion resistance and is often given a zinc coating just to resist oxidization. Manganese, vanadium and tungsten are just some of the other elements added to improve the steel.

- Q: Can steel coils be used in the manufacturing of machinery and equipment?

- Machinery and equipment manufacturing can indeed utilize steel coils effectively. These coils possess remarkable versatility and contribute strength, durability, and stability to various industrial applications. They can be manipulated to assume various shapes, receive cuts, and undergo formation to generate diverse parts and components that are indispensable to the manufacturing process of machinery and equipment. Gears, shafts, frames, brackets, and other structural elements are commonly produced using steel coils. Moreover, these coils can undergo further processing to fashion specialized components like springs or fasteners. By incorporating steel coils into machinery and equipment manufacturing, the end products are guaranteed to possess exceptional quality, capable of enduring heavy loads, and boasting an extended lifespan.

- Q: I am working on a hydrogen generator, but the stainless steel I am using corrodes and turns the water brown. Can anyone tell me if there is stainless steel that does not corrode, and if so, what is it called and where can I get some.Thank you.

- You are not using stainless steel.

- Q: How are steel coils used in the production of electrical systems?

- Steel coils are used in the production of electrical systems as they serve as the core component of transformers and inductors. They provide a magnetic field necessary for the efficient functioning and transformation of electrical energy.

- Q: what is tool steel and does it function better than carbon or spring steel?

- Yes, its good for machining, but it needs to be hardened once machined. Steel in itself is very weak, but when tempered it can become 10x stronger. Once shaped, heat the sword with a torch until it starts to change color, then dip it into a vat of oil, not water, and the rapid cooling when reform the atoms of the steel. Heres an article about the process:

- Q: What dangers were there for the steel workers in Pittsburgh under Carnegie?

- Same as other steel plants, getting crushed by falling steel, getting burned by hot metal etc

- Q: How are steel coils annealed to improve their properties?

- Steel coils are annealed to improve their properties through a process called annealing, which involves heating the coils to a specific temperature and then slowly cooling them. This process helps to relieve internal stresses, enhance ductility and toughness, and refine the grain structure of the steel, resulting in improved mechanical properties such as increased strength and reduced brittleness.

- Q: hey i was looking to buy a khukuri machete by cas iberia. its made of carbon steel but doesnt say which one. anyone that is into knives and all that know how this would hold up and the rust resistance of it? mostly be used for cutting bush and small trees

- There's no way to tell from the information you posted. Given it's for a machete I would guess it would be a fairly high carbon steel. Rust resistance will be relatively poor. It will last for years though as long as you clean and dry it after use.

- Q: How are steel coils used in the manufacturing of suspension systems?

- Steel coils are commonly used in the manufacturing of suspension systems as they provide the necessary support and flexibility to absorb shocks and vibrations. These coils are typically shaped into springs and placed in the suspension system of vehicles, helping to maintain stability, improve handling, and ensure a smooth ride by absorbing the impact from uneven surfaces on the road.

Send your message to us

Color coated galvanized rolled steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords