Best Quality for White Prepainted Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 10000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

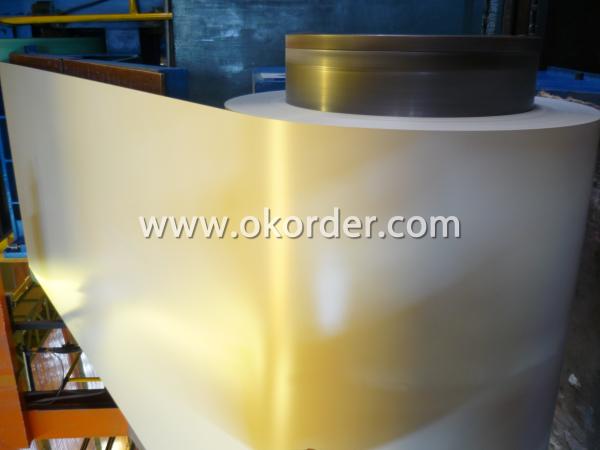

General Information of White Prepainted Galvanized Steel

With GI as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Specification of White Prepainted Galvanized Steel:

1. Thickness 0.23-1.2mm (BMT)

2. Zinc Coating 80-275g/m2

3. Color According to RAL color fan Internal

4. Diameter 508mm or 610mm

5. Coil Weight 4-8MT

6. Quality Commercial and structural quality

7. Paint Polyester paint for topside, epoxy for reverse

8. Standard JIS G 3312, ASTM A755M, EN 10169

9. Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS

Chemical Composition of White Prepainted Galvanized Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data of White Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Application of White Prepainted Galvanized Steel

Outdoor:

roof, roof structure, surface sheet of balcony,

frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, etc.

In door:

door, isolater, frame of door, light steel structure of house, home electronic appliances, etc.

Packaging & Delivery of White Prepainted Galvanized Steel

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q: How is steel plate cut and shaped?

- Steel plates can be cut and shaped using various methods such as thermal cutting (using oxy-fuel or plasma), mechanical cutting (shearing or sawing), or laser cutting. Once the initial cutting is done, the steel plate can be further shaped through processes like bending, rolling, or forming to achieve the desired dimensions and contours. These methods ensure precise and accurate cuts and shapes, allowing steel plates to be used in a wide range of applications.

- Q: What are the different grades of steel and their respective applications?

- There are several different grades of steel, each with its own unique properties and applications. Some common grades include stainless steel, which is resistant to corrosion and widely used in kitchen utensils and appliances; carbon steel, which is strong and versatile, often used in construction and automotive industries; alloy steel, which contains various elements to enhance strength, durability, and heat resistance, commonly used in machinery and tools; and tool steel, specifically designed for making tools due to its high hardness and wear resistance. Additionally, there are specialized grades such as weathering steel, used for outdoor structures, and heat-resistant steel, used in high-temperature environments like furnaces and boilers.

- Q: What are the different types of steel products used in the energy sector?

- Some of the different types of steel products used in the energy sector include pipes and tubes for oil and gas transportation, structural steel for power plant construction, steel plates for offshore drilling platforms, and steel wires for electrical transmission lines.

- Q: How are steel gratings used in the construction of industrial platforms?

- Steel gratings are commonly used in the construction of industrial platforms to provide a strong and durable flooring solution. These gratings are designed to support heavy loads and provide a safe walking surface for workers. They are often used in areas where there is a need for ventilation, drainage, or visibility. Overall, steel gratings play a crucial role in enhancing the stability, safety, and functionality of industrial platforms.

- Q: What are the different types of steel coils and their uses?

- There are several types of steel coils, including hot rolled, cold rolled, galvanized, and stainless steel coils. Hot rolled coils are commonly used in construction and manufacturing industries for structural applications. Cold rolled coils are used in automotive, appliance, and electrical industries for their superior surface finish and dimensional accuracy. Galvanized coils are coated with a layer of zinc, making them corrosion-resistant and suitable for outdoor applications. Stainless steel coils are highly resistant to corrosion and heat, making them ideal for food processing, medical, and chemical industries.

- Q: What are the different types of steel cladding and roofing available?

- There are several different types of steel cladding and roofing available, including corrugated steel, standing seam steel, and steel shingles. Corrugated steel is a popular choice for agricultural and industrial buildings due to its durability and cost-effectiveness. Standing seam steel offers a more modern and sleek appearance, with interlocking panels that create a continuous and watertight roof surface. Lastly, steel shingles are designed to resemble traditional roofing materials like wood or slate, providing a versatile and aesthetically pleasing option for residential and commercial buildings.

- Q: What are the common types of steel products used in the telecommunications industry?

- Some common types of steel products used in the telecommunications industry include steel poles, towers, and cabinets. These steel structures provide the necessary support and protection for telecommunication equipment and infrastructure.

- Q: What are the different types of steel beams and their applications?

- There are several types of steel beams commonly used in construction and their applications vary based on their characteristics. Some of the common types include I-beams, H-beams, and T-beams. I-beams, also known as W-beams, have a characteristic shape resembling the letter "I". They are widely used in construction due to their high strength-to-weight ratio and are commonly used in structural support applications such as building frames and bridges. H-beams, also known as wide flange beams, have a shape resembling the letter "H". They are often used in structural applications that require heavy loads, such as columns and retaining walls. H-beams offer excellent bending and shear resistance, making them suitable for various construction projects. T-beams, also known as Tee beams, have a shape resembling the letter "T". They are commonly used in reinforced concrete structures, where they provide support for slabs and beams. T-beams are typically used in applications such as floor and roof systems, as well as bridge decks. Each type of steel beam has its own unique properties and applications, and the choice of beam depends on the specific requirements of the construction project.

- Q: What are the different types of steel fasteners and their applications?

- There are several different types of steel fasteners commonly used in various applications. Some of the most common types include bolts, screws, nuts, and washers. Bolts are threaded fasteners that are used to join two or more components together. They come in different sizes and strengths, making them suitable for a wide range of applications such as construction, automotive, and machinery. Screws are similar to bolts but have pointed ends and are typically used to secure objects to a surface or to hold components together. Nuts are threaded fasteners that are used in conjunction with bolts to create a secure joint. They provide additional stability and can be easily tightened or loosened. Washers are flat, disk-shaped fasteners that are placed between a nut or bolt head and the surface of the material being fastened. They help distribute the load and prevent damage to the material. Overall, steel fasteners are essential components used in various industries for their strength, durability, and versatility.

- Q: What are the applications of steel forgings in the oil and gas industry?

- Steel forgings have several applications in the oil and gas industry due to their strength, durability, and resistance to extreme conditions. They are commonly used in the production of drilling equipment, such as drill bits, drill collars, and drill stems, as well as in the manufacturing of valves, pumps, and pipelines. Steel forgings are crucial for withstanding high pressures, corrosive environments, and intense heat, making them essential components in the extraction, processing, and transportation of oil and gas.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2003 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Southern Asia; America; South America; Eastern Europe |

| Company Certifications | ISO 9000 ISO 14000 OHSAS 18000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 200,000 square meters |

| No. of Production Lines | 14 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for White Prepainted Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 10000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords