GB Q235 Cr Steel Billets China Manufacture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Description

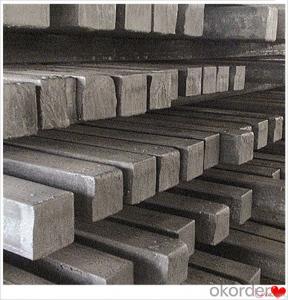

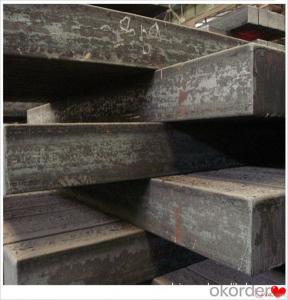

GB Q235 Steel Billets

| Product Name | Steel Billets |

| Size | 60×60mm, 100×100mm, 120×120mm, 130×130mm, 150×150mm |

| Length | 6M, 9M, 12M |

| Grade | Q235 |

| Standard | GB |

| Chemical Composition | Q235: C: 0.14-0.22% MN: 0.3-0.7% SI: 0.3% max P: 0.045%max S: 0.045%max |

2. Product Picture

3. FAQ

1. Q: How can I visit there?

A: Our company is located in China. Welcome to visit us.

2. Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

3. Q: What's the MOQ?

A: Our MOQ is 25mt.

4. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

5. Q: What is the payment terms?

A: T/T, L/C at sight

6. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

7. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

4. Shipment:

Logistic department established and serves for sales department. Cargo is delivered to the port by our own trucks. Both bulk and container service are available and cargo shipment is in hands of logistic staffs.

- Q: How is steel used in the production of medical equipment?

- Steel is commonly used in the production of medical equipment due to its strength, durability, and resistance to corrosion. It is utilized in various medical instruments, such as surgical tools, implants, and prosthetics, to ensure their longevity and reliability during procedures and treatments. Additionally, stainless steel, a type of steel with high resistance to rust and stains, is commonly used in medical equipment as it can be easily sterilized, making it suitable for maintaining a clean and hygienic environment in healthcare settings.

- Q: What are the different types of steel wires and their applications in telecommunications?

- There are several types of steel wires commonly used in telecommunications. These include galvanized steel wires, stainless steel wires, and high-tensile steel wires. Galvanized steel wires are coated with a layer of zinc, which provides corrosion resistance and durability. They are commonly used for overhead transmission lines, telephone cables, and fiber optic cables. Stainless steel wires are highly resistant to corrosion and have excellent strength properties. They are often used in marine environments, underground installations, and for aerial cables where high tensile strength is required. High-tensile steel wires are known for their exceptional strength and toughness. They are used in applications where heavy loads and long spans are involved, such as suspension cables for bridges and power transmission lines. Overall, these different types of steel wires play a crucial role in the telecommunications industry by providing strength, durability, and reliability for transmitting signals and supporting communication infrastructure.

- Q: How is steel used in the manufacturing of textile materials?

- Steel is used in the manufacturing of textile materials through various applications such as the construction of textile machinery, production of textile accessories like pins, needles, and hooks, as well as in the manufacturing of textile machinery parts, tools, and equipment. Additionally, steel is also utilized for the construction of textile factories and warehouses, providing the necessary structural support and strength for these facilities.

- Q: How does the quality of steel affect its performance?

- The quality of steel directly impacts its performance. Higher-quality steel possesses superior strength, durability, and resistance to wear and tear. It also exhibits better heat conductivity and corrosion resistance, making it more suitable for various applications. Conversely, lower-quality steel may be more prone to breakage, deformation, and rapid deterioration, resulting in compromised performance and potentially unsafe conditions.

- Q: How is steel used in the manufacturing of transportation equipment?

- Steel is widely used in the manufacturing of transportation equipment due to its strong and durable nature. It is utilized in the construction of car bodies, truck frames, and railway tracks, providing the necessary strength and stability required for safe and efficient transportation. Additionally, steel is used in the production of aircraft, ships, and even bicycles, as it offers excellent resistance to corrosion and can withstand extreme conditions.

- Q: How are steel gratings used in industrial flooring?

- Steel gratings are commonly used in industrial flooring as they provide a strong and durable surface for heavy machinery and equipment to operate on. They are designed with an open grid structure, allowing for easy drainage of liquids, debris, and other waste materials. This helps to maintain a clean and safe working environment by reducing the risk of accidents caused by slipping or tripping. Additionally, steel gratings offer excellent load-bearing capabilities, making them ideal for supporting heavy loads and providing structural stability in industrial settings.

- Q: How are steel pipes used in the transportation of natural gas?

- Steel pipes are used in the transportation of natural gas as they provide a reliable and durable means of transporting the gas over long distances. These pipes are designed to withstand high pressure and are resistant to corrosion, making them suitable for the transmission of natural gas. Additionally, steel pipes are able to maintain the integrity of the gas, ensuring minimal leakage and loss during transportation.

- Q: How are steel products used in the food processing industry?

- Steel products are widely used in the food processing industry for a variety of applications. They are used to manufacture machinery and equipment such as mixers, conveyors, and cutting tools, which are essential for processing, packaging, and storing food products. Steel is preferred due to its durability, resistance to corrosion, and ability to withstand high temperatures and harsh conditions. Additionally, stainless steel, a type of steel that contains chromium and nickel, is commonly used for food contact surfaces, storage tanks, and utensils as it is hygienic, easy to clean, and prevents contamination. Overall, steel products play a crucial role in maintaining food safety, efficiency, and quality in the food processing industry.

- Q: What are the different types of steel forgings and their uses?

- There are several types of steel forgings, each with its own unique properties and uses. Some common types include open-die forgings, closed-die forgings, and seamless rolled ring forgings. Open-die forgings are used for large and complex parts, such as turbine shafts and pressure vessels. Closed-die forgings are ideal for smaller and intricate components like automotive parts and hand tools. Seamless rolled ring forgings are commonly used in applications requiring high strength and durability, such as gears, bearings, and flanges. Overall, steel forgings offer superior strength, reliability, and resistance to wear, making them essential in various industries including aerospace, automotive, and oil and gas.

- Q: What are the different types of steel flooring and decking available?

- There are several types of steel flooring and decking available, including steel grating, steel checker plate, and steel floor decking. Steel grating consists of interlocking bars or grids that provide a strong and durable flooring solution. Steel checker plate features raised patterns or diamond-shaped projections that enhance slip resistance and aesthetic appeal. Steel floor decking is a popular choice for construction projects, as it provides a sturdy and cost-effective solution for creating elevated floors and mezzanines.

Send your message to us

GB Q235 Cr Steel Billets China Manufacture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords