Pf1 Staple Fiber Needle Punched Non Woven Geotextile Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

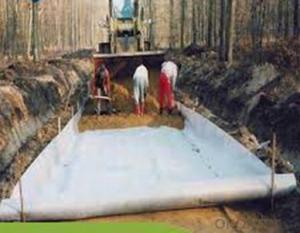

Application range

1.Reinforcement: Used in the constructions of highway, railway, airport, dam, prevent slope dike, retaining wall, etc. to improve stability.

2.Protection: To prevent the bank from eroding by wind, wave ,tidal and rain. Used for the projects such as revetment, slope protection and bottom protection, anti-soil erosion,etc.

3.Filtration: Used as filtering layer of dike, the dam, river and coast stone , slope, retaining wall to prevent sand grain through and allow freedom through of air or water.

1. Filtration of soils in drainage applications by retaining soil particles while allowing for the free flow of

water

2.Separation and stabilization in road and railway construction

3.Prevention of soil movement in erosion control measures

4.Cushioning and protection in many containment projects

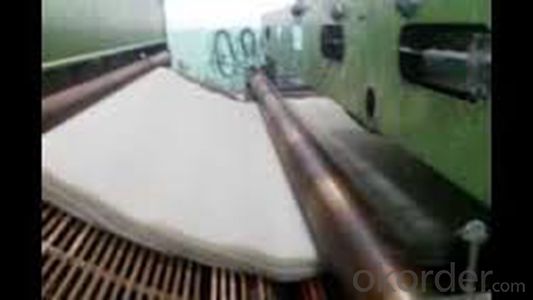

Detailed Images

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used for erosion control in beach nourishment projects?

- Yes, geotextiles can be used for erosion control in beach nourishment projects. Geotextiles are permeable fabrics that can be placed to stabilize the beach and prevent erosion by trapping sediment and allowing water to drain through. They are commonly used to reinforce and protect shorelines during beach nourishment projects.

- Q: What is the expected lifespan of geotextiles?

- The expected lifespan of geotextiles can vary depending on factors such as the quality of the material, the specific application, and the environmental conditions. However, on average, geotextiles are designed to have a lifespan of 20-30 years.

- Q: What are the factors to consider when designing geotextile-reinforced structures?

- When designing geotextile-reinforced structures, there are several factors that need to be considered. Firstly, the type and properties of the geotextile being used must be evaluated, including its strength, durability, and permeability. The soil conditions at the site, such as its composition, stability, and drainage characteristics, also play a significant role. The design should take into account the anticipated loads and stresses that the structure will be subjected to, as well as any potential environmental factors such as rainfall or seismic activity. Additionally, construction considerations, including the installation process, available equipment, and cost-effectiveness, should be taken into account. Overall, a comprehensive understanding of the site conditions, geotextile properties, and design requirements is crucial to ensure the successful and sustainable design of geotextile-reinforced structures.

- Q: How do geotextiles prevent soil contamination?

- Geotextiles prevent soil contamination by acting as a barrier that separates the soil from potentially harmful substances, such as pollutants or contaminants. It helps to filter and retain these substances, preventing them from leaching into the soil and affecting its quality. Geotextiles also aid in erosion control, reducing the risk of soil contamination caused by sediment runoff.

- Q: Geotextile longitudinal and lateral elongation gap is too much how to adjust

- 1. The elongation at break of the geotextile is divided into longitudinal elongation at break and transverse elongation at break. Generally speaking, the elongation at longitudinal and transverse faults is not very different. GB GB / T-2008 standard requirements geotextile longitudinal and lateral elongation between 20% -100% are qualified. 2. Longitudinal transverse fracture elongation gap is too large, you can check the mixing hopper, carding machine is mixed evenly, combing evenly. 3. Acupuncture machine too fast or too high acupuncture may lead to geotextile longitudinal and transverse elongation gap, you can try to debug the speed of the next needle machine. 4. Appropriate to add some industrial oil can enhance the geotextile rupture strength, and elongation at break.

- Q: What kind of geotextile is used to repair the road?

- Geotextile in the application of the road: a slope care, specifications in the 250-350g / m2 its role has the following three points: 1. filter when the water from the fine soil into the coarse soil layer, the use of polyester staple fiber Acupuncture geotextile good permeability and water permeability, so that water through, and effectively carrying soil particles, sand, small stone, etc., in order to maintain the stability of soil and water engineering. 2. Drain polyester staple fiber geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of excess liquid and gas efflux. 3. Protection of water flow on the soil erosion, the effective concentration of concentrated diffusion, transmission or decomposition, to prevent the soil by external forces and damage. Second, the foundation treatment, the main role is to strengthen. The use of polyester staple acupuncture geotextile to enhance the soil tensile strength and resistance to deformation, enhance the stability of the building structure to improve soil quality. Specifications not low 400g / m2. The main role is to use the polyester staple fiber geotextile with different physical properties (particle size, distribution, consistency and density, etc.) of the building materials (such as soil and sand, soil and concrete, etc.) ) To isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the building capacity to enhance the capacity. Specifications in the 150-400g / m2

- Q: Geotextile price is how much money

- Ask the geotextile price is too general, because the standard too much. Short wire, filament, polyester; non-standard, GB and so on. To Hongxiang Li Qian short wire geotextile price quote, for example, the price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan /Ton. 187 & lt; 6600 & lt; 5604

- Q: What is the length of the lap in the geotextile in the tunnel?

- General 20cm can be, I produce geotextile materials

- Q: Are geotextiles suitable for use in bridge construction?

- Yes, geotextiles are suitable for use in bridge construction. Geotextiles provide several benefits such as soil stabilization, erosion control, and drainage, which are crucial in bridge construction to enhance the overall performance and longevity of the structure.

- Q: Are geotextiles resistant to hydrostatic pressure?

- Yes, geotextiles are generally resistant to hydrostatic pressure. They are designed to have high tensile strength and durability, which allows them to withstand the pressure exerted by liquids or water.

Send your message to us

Pf1 Staple Fiber Needle Punched Non Woven Geotextile Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords