Silicate Calcium Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

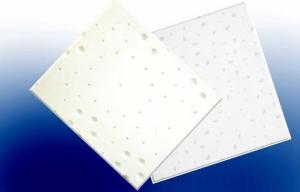

calcium silicate board

a kind of "green material" board, special environment-protecting function makes it superior to other boards with dampproof and fire prevention capability.

Its main basic material is calcium and silicon, and natural fabric strengthen it, other auxiliary material mixed, under the condition of high temperature, high pressure nourish, then it is made. This kind of product does not contain any asbestos.

calcium silicate board Standard Specifications:

1) 2440 × 1220 × 4.5-18MM

2) 2400 × 1220 × 4.5-18MM

3) 3050× 1220 × 5-18MM

4) 3660× 1220 × 5-18MM

The other specification is also avaliable

calcium silicate board Main mechanical performance:

density(g/cm) | 1.2-1.4 | |

antiflex cracking strength(Mpa≥) | 12 | |

pulling-out force of screw (N/mm ≥) | 80 | |

Thermal conductivity (w m.k ≤ ) | 0.3 |

|

Moisture content (% ≤ ) | 10 | |

incombustibility

| ClassA | |

calcium silicate board Main Characteristics:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

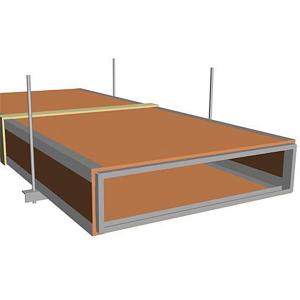

calcium silicate board Main Usage:

1)partitioning wall

2)internal and external wall bodies

3)ceiling

4)flooring

it is suitable for places such as meeting room ,

hotel,factory building ,theater ,hall ,bathroom and so on

Packing:

with strong wooden pallets

Loading quantity :

Specs | Q'ty/1x20ft | Weight(Kgs) | Volume(m3) |

1220mmx2440mmx6mm | 820pcs | 21000 | 20 |

1220mmx2440mmx9mm | 540pcs | 21000 | 20 |

1220mmx2440mmx12mm | 410pcs | 21000 | 20 |

- Q: My family in the north of the countryside, when the original building, the guest 粻 chicken class Tuen Jiu halo Mo hall with a high 1 meter wide and 50 cm tiles close to the wall around the circle, his wife said it looked good, do not want Yes, but the original is attached to the wall with cement, not easy to get down. I would like to ask, can not use gypsum board or plywood stick to the top, how to get, thank you! More

- Hurry to knock it! In the above coated with a layer of cement it!

- Q: How to install silicon calcium board ceiling

- Silicon calcium board ceiling is the main advantage of light, waterproof, sound absorption, construction is simple. 16X28 "T" type aluminum alloy keel, 16X28 "T" type aluminum alloy main keel, 12X18 "L" shaped aluminum alloy keel 2 , The main machine saws, tooth saws, hand saws, impact hammers, electric screwdrivers, hand planets, pliers, wrenches, level, by the foot, steel tape three, the construction trace trace tube called Environmental walls around the play a good roof + 50cm level elevation control line, and verification is completed. Install the roof of the various lines and ventilation ducts, to determine the light, ventilation and a variety of exposed Ming mouth position. And check the height of the ceiling and its equipment within the impact of elevation. Check whether the materials and fittings used are well prepared. Before the keel, you must complete the wet work on the wall surface. Erected a roof construction platform. Silicon calcium plate keel ceiling in a large area before the construction, should do the model, the roof of the arched, light tank, vents of the tectonic treatment, block and fixed methods should be tested and identified after a large area of ??construction The Fourth, the construction process of the standard high-level standard, designated keel pieces - fixed hanging pieces - installation side keel - the installation of the main keel - installation sub-keel - cover panel installation

- Q: Calcium silicate board can be recycled

- No recycling, crushing has no effect on the environment

- Q: Calcium silicate board does not paint it

- Look at how specific you use, do not brush paint is also possible

- Q: Fiber cement pressure plate and calcium silicate board What is the difference, what is the use

- Hardness is not the same!

- Q: Buy the house is fine decoration, wood flooring poor quality to tile bathroom ceiling is calcium silicate board, it is necessary to replace it? Need to change the material of the ceiling?

- Bathroom ceiling can be changed to aluminum slab ceiling, more atmospheric

- Q: I want to put tiles on the board. Do not want to use aluminum plate more

- The cement board is better resistant to moisture

- Q: Is the calcium silicate board combustible? Some people say that it is completely non-combustible material, it was said that calcium silicate board only need one positive and one 8mm board to achieve one hour fire

- Calcium silicate board is non-combustible material, can do 1 hour fire aging.

- Q: Please specify the specific time and the problem, thank you, calcium silicate board is Han Debang, medium density, colorful paint is Pan Cai, imitation stone more

- Calcium silicate board is not changed in the water, if the time is long, then the strength will be weakened some, but if the dry wall of the sub-wall than the words of the words will resume the original strength

- Q: Decoration problem: a calcium silicate board about how many customers want me to calculate the weight. The Trouble trouble trouble. The The

- 1 OKorder twitch high libel gambling gambling performance 220 * 2440 * 6 calcium silicate board normal weight in 22kg. 6 refers to the thickness of the ceiling now more than 5%, 5% is generally 18kg. Under the premise of fixed specifications, mainly depends on the bulk density. However, due to the manufacturers of different recipe technology, bulk density will be a little different. Please add points.

Send your message to us

Silicate Calcium Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords