Exterior wall decoration fire insulation board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

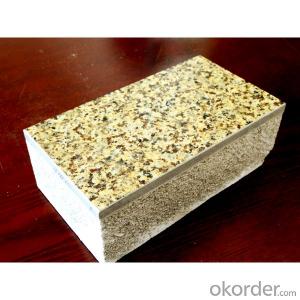

Insulation and decoration board

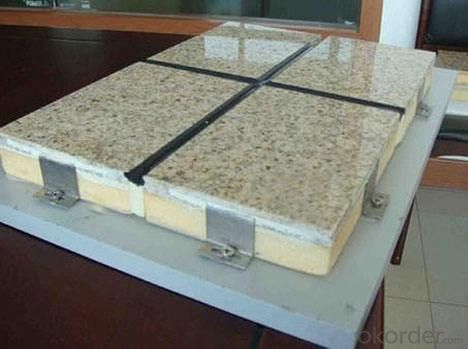

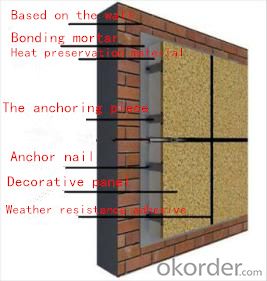

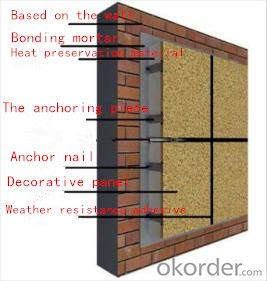

The insulation panel is composed of insulating materials, adhesion, veneer, anchoring and sealant. There are many construction schemes, which not only apply to the external wall insulation and decoration of new buildings, but also apply to energy saving and decoration transformation of old buildings. It is applicable to all kinds of public buildings and exterior insulation of residential buildings. It is suitable for buildings in cold areas in the north and in hot areas of the south. It's a new type of building material. Heat preservation to decorate a whole plate is placed in the building wall insulation and decoration on the surface of the system, the heat preservation effect is good and long term, less thermal bridge role, energy saving heat preservation effect is good, according to 65% of building energy efficiency design requirements, than the traditional energy-saving insulation heat preservation and heat insulation construction practice with more and better function.

Each composition by heat preservation to decorate a whole plate bonding, such as mechanical, chemical or physical way between structure component of the similar or close to, therefore, even in temperature, sunshine, rain, frost, cold, heat, acid and alkali, such as under the bad environment, can guarantee the system stability.

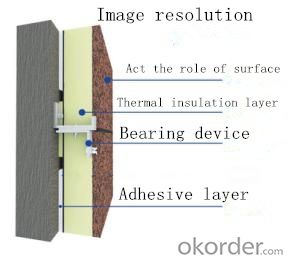

Introduction to product structure:

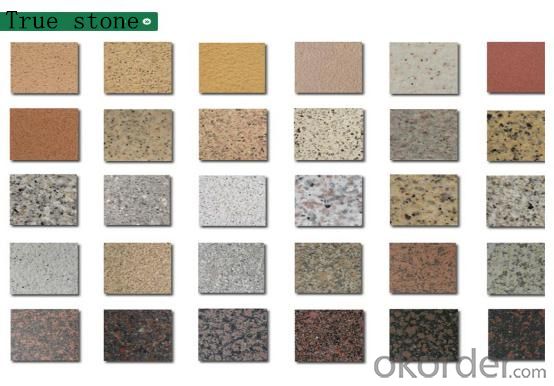

Act the role of surface:.True stone paint, liquid granite, solid paint, fluorocarbon paint, aluminum plate, clay board, etc.

Thermal insulation layer:

AClass A fire:Silicon polystyrene board, rock wool and so on

BClass B fire: Extruded plate, polystyrene board, polyurethane, phenolic and so on

Installation method:

Advantages of the insulation panel:

1 Convenient construction,

2 Decorative,

3 Security,

4 Fire retardancy,

5 Thermal insulation,

6 Weather resistance,

7 Waterproof breathability.

Engineering cases:

- Q: My home decoration ceiling, decoration company reported is easy to licensing calcium carbonate board to do smallpox, how ah, environmental protection? And the concrete board to identify it

- Asbestos plate to see if the broken surface is a bunch of uneven dark gray flocculent fiber, this is the point of noncombustible. In addition, if it is a small plate ceiling, keel requirements are not large, if it is a large plate ceiling, pay attention to the steel keel will have a cat amount of money, may give you shoddy, this kind of thing to see a lot, the other can be considered with wood keel Ceiling, to do the anti-corrosion treatment of wood is good, mainly to prevent the filling putty cracking, because the steel keel on the vibration of the buffer is almost, or use elastic putty or AB glue filling, but also worry about bad, you can use Seam processing. Above are doing the words, basically with the housing with the birthday.

- Q: The real production of non-asbestos calcium silicate board manufacturers which is the company, and now all the calcium silicate board manufacturers are blowing their own asbestos-free, hoping to have a real asbestos

- This, the need to identify, as far as I know, Zhejiang Huzhou Taiwan Rongliang building materials board is really no asbestos, Etneite board is also non-asbestos, the other I can not pretend to comment.

- Q: How to distinguish between the color of calcium silicate board is good or bad

- Color distinction Calcium silicate board is good or bad: Direct visual observation to identify: If the hands of a calcium silicate board of the sample, then look directly at its side, to see the side is not a lot of small white spots, those white spots that is asbestos.

- Q: High purity calcium silicate board with what cut

- Temperature 1050 degrees, very light that kind of soft This is easy to cut it, the manufacturer anyway, is cut with electric saw blade, personal processing, then worry about too light dust, hand saw knife can be.

- Q: What is calcium silicate board?

- Part of my finishing part of the hair you see: fiber reinforced calcium silicate board (referred to as calcium silicate board) is inorganic mineral fiber or cellulose fiber and other loose fiber as a reinforcing material to calcium - siliceous material as the main cementing material , By the pulp, into the blank and high pressure steaming and other processes made of new environmentally friendly energy-saving sheet.

- Q: Is the perforated calcium silicate wallboard used in wall decoration?

- Calcium silicate wallboard is used in the wall decoration, this is possible, but the life of this material is not commonly used brick wall is good, after all, calcium silicate board wall is a thin layer, do not want us Housing, as the use of sex is not very high, but in the activity board room usage is still very high.

- Q: Does the apartment use silicon calcium board to make the wall right?

- Calcium silicate board shortcomings: 1, the installation of calcium silicate board, the compartment would like to change, the replacement is not easy. 2, the installation of metal keel need to use, more cumbersome works, the price is more expensive.

- Q: Calcium silicate with quartz powder is the number of requirements! How much silicon content?

- Calcium silicate board preparation of quartz powder with the general requirements: Silica content: greater than or equal to 93 (%) Melting point 1600 (℃) Mohs hardness: conventional Common specifications: 100 - 325 head Color: gray, grayish yellow Suitable for the production of calcium silicate board and other calcium silicate products

- Q: Calcium silicate board do background wall Why choose uv printer

- Uv printer without plate, that is, that is dry, print size depends on the printer to print the size, of course, can also block print, print material small to the box, cosmetic box, u disk, large glass, tiles, Metal plate, acrylic, etc., as long as the plane material can print, because it can print a wide range, it is also called universal printer, select the appropriate print material, set up a good printer like, not only can print 3d effect, but also Print relief effect. Print the background wall relief principle, through the computer graphics software to outline the lines to print, through the UV printer to print up. Principle is the first accumulation of white ink outline lines, and then on the color, print depth is 5mm.

- Q: Calcium silicate board is not keel, you can directly nail on the wall?

- No, the same dragon skeleton. If you do not have a direct steel wall keel, directly with a wooden keel on it

Send your message to us

Exterior wall decoration fire insulation board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords