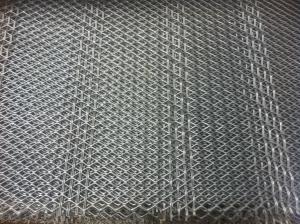

Stainless Steel Wire Mesh Panel Hot Sale and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material:

201,202,302,304,304L,316,316L

Guage:

1.wire diameter:0.1-3.0mm

2.Mesh: 1-650mesh.

3.Width:0.5-5m

3.Length:30m

Weave way

Dutch weave

Plain weave

Twill weave

Stainless steel wire mesh kind:

1, stainless steel plain weave mesh. 2, stainless steel twill mesh. 3, stainless steel mesh bamboo pattern. 4, five mechanized stainless steel mesh. 5, stainless steel perforated metal mesh. 6, stainless steel crimped wire mesh. 7, stainless steel chain link fence. 8, stainless steel mesh. 9, stainless steel welded wire mesh. 10, stainless steel hexagonal. 11, stainless steel I-Net. 12, stainless steel wire meshes. 13, stainless steel mine screen. 14 mesh stainless steel shells.

- Q: How do steel pipes compare to other materials, such as PVC or copper?

- Steel pipes are generally more durable and have a higher resistance to heat, pressure, and corrosion compared to PVC or copper pipes. They are commonly used for applications that require strength and longevity, such as in industrial settings or for transporting high-pressure fluids. However, steel pipes can be more expensive and heavier than PVC or copper, making them less suitable for certain residential or lightweight applications. Ultimately, the choice of material depends on the specific requirements and budget of the project.

- Q: Can steel pipes be bent or curved?

- Yes, steel pipes can be bent or curved using specialized machinery and techniques such as cold bending, induction bending, or hot bending.

- Q: How do you repair damaged steel pipes?

- To fix steel pipes that have been damaged, there are several steps you can take: First, you need to determine the extent of the damage. Assess how severe it is to decide if you can repair it or if you need to replace the entire pipe. Next, isolate and drain the section that is damaged. Shut off the water supply to that part of the pipe and drain any remaining water to prevent further leaks or damage. After that, clean the damaged area by removing any dirt, rust, or debris. You can use a wire brush or sandpaper for this job. Then, prepare the damaged area by roughening the surface with coarse sandpaper. This will help the repair material adhere better to the pipe. Next, choose a repair method based on the size and location of the damage. There are different options available such as using epoxy putty, pipe wraps, or clamps. Once you've chosen a repair method, follow the instructions provided to apply the repair material to the damaged area. Make sure it covers the entire damaged section and extends slightly beyond it for added protection. After applying the repair material, allow it to cure according to the manufacturer's instructions. This will ensure a strong bond and effective sealing of the damaged area. Once the repair has cured, turn the water supply back on and check for any leaks. If there are no signs of leakage, then the repair has been successful. If there are still leaks, you may need to reconsider the repair or seek professional help. Keep in mind that these steps are a general guideline for repairing damaged steel pipes. The specific repair method may vary depending on the size and severity of the damage. In more complex cases or if you're unsure, it's best to consult a professional plumber or pipe repair specialist.

- Q: Are steel pipes suitable for underground chemical transport?

- Steel pipes are widely regarded as appropriate for transporting chemicals underground because of their high strength and durability. They have the ability to endure the pressure and weight of the soil above, rendering them impervious to harm or collapse. Furthermore, steel pipes possess corrosion resistance, which is vital when conveying chemicals that might react with or corrode other substances. They also have the capability to handle a wide range of temperatures, making them suitable for transporting chemicals that necessitate specific temperature conditions. Nevertheless, it is crucial to carefully consider the particular chemical being transported and seek advice from experts in chemical engineering or pipeline design to guarantee the compatibility of the steel pipes with the chemical and the implementation of any necessary safety precautions.

- Q: How are steel pipes tested for quality assurance?

- Steel pipes are tested for quality assurance through various methods including visual inspection, non-destructive testing (such as ultrasonic testing and magnetic particle inspection), mechanical testing (such as tensile strength and hardness testing), and dimensional checks. These tests help ensure that the pipes meet the required specifications, standards, and safety regulations, ensuring their durability, reliability, and performance in various applications.

- Q: Can steel pipes be used for fencing or railing?

- Yes, steel pipes can be used for fencing or railing. Steel pipes are strong, durable, and resistant to corrosion, making them a suitable option for fencing or railing applications. They can provide a sturdy and secure barrier while also offering an aesthetically pleasing look.

- Q: How are steel pipes classified based on their end connections?

- Steel pipes can be classified based on their end connections into threaded, socket weld, butt weld, and flanged connections.

- Q: What is a flange and how is it used in steel pipes?

- A flange is a mechanical device that is used to connect two sections of steel pipes together. It consists of a flat or raised ring that is attached to the end of each pipe section. The flange provides a surface for the pipes to be bolted or welded together, creating a secure and leak-proof joint. It also allows for easy disassembly and reassembly of the pipes when necessary. Flanges are commonly used in various industries, such as oil and gas, water treatment, and manufacturing, where the connection between steel pipes needs to be strong and reliable.

- Q: Can steel pipes be used for high-temperature applications?

- Yes, steel pipes can be used for high-temperature applications. Steel is known for its excellent strength and durability, making it suitable for handling high temperatures. However, the specific grade of steel used and the operating conditions must be considered to ensure it can withstand the desired temperature range without compromising its structural integrity.

- Q: Do steel pipes expand or contract with temperature changes?

- Steel pipes expand when subjected to an increase in temperature and contract when exposed to a decrease in temperature. This phenomenon is a result of the thermal expansion and contraction properties of steel, which is a characteristic of most materials. When steel pipes are heated, the molecules within the metal gain energy and vibrate more vigorously, causing them to move apart and expand in size. Conversely, when the temperature of the steel pipes decreases, the molecules lose energy and move closer together, resulting in a contraction or shrinkage in size. It is important to consider these thermal expansion and contraction properties of steel pipes when designing and installing them, as failure to account for these changes may lead to structural damage, leaks, or other issues.

Send your message to us

Stainless Steel Wire Mesh Panel Hot Sale and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords