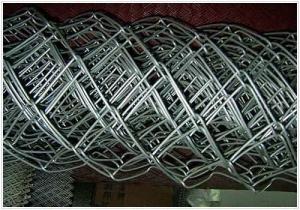

High Quality Stainless Steel Wire Mesh Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Material: | Type: | |||

| Application: | Weave Style: | Wire Diameter: | |||

| Technique: | Model Number: | Brand Name: | |||

| product name(stainless steel mesh): | stainless steel wire mesh usage: | stainless steel mesh other using: | |||

| stainless steel net characteristic: | stainless steel net other characteristic: | Stainless steel mesh deep processing: | |||

| Stainless steel net Further processing: | Stainless steel wire mesh weave: | Stainless steel wire mesh: | |||

| Stainless steel wire mesh wire diameter: |

Packaging & Delivery

| Packaging Detail: | packing:waterproof paper inside, plastic film outside, then pallet or wooden box. Stainless Steel Wire Cloth |

| Delivery Detail: | 10-15 day Stainless Steel Wire Cloth |

Specifications

Stainless Steel Wire Cloth

stainless steel mesh use very broad

wire mesh/filte net/wire cloth

Texture/SS304,316,430,201,320

- Q: Can steel wire mesh be used for tree guards?

- Yes, steel wire mesh can indeed be used for tree guards. Steel wire mesh is a durable and strong material that can effectively protect young trees from animals, pests, and other potential damage. The mesh provides a physical barrier around the tree, preventing animals from chewing on the bark or damaging the trunk. It also helps to keep away small rodents, such as rabbits or mice, that may gnaw at the tree's roots. Additionally, steel wire mesh can act as a support system by preventing the tree from leaning or being damaged by strong winds. Overall, steel wire mesh is a practical and effective choice for tree guards due to its strength, durability, and ability to provide protection.

- Q: What are the temperature resistance properties of steel wire mesh?

- The temperature resistance properties of steel wire mesh are excellent, as it can endure high temperatures without compromising its structural integrity or experiencing significant thermal expansion. The steel grade and composition determine the specific temperature resistance of the wire mesh, but in general, it has a high melting point and can withstand temperatures up to 1,500 degrees Celsius (2,732 degrees Fahrenheit) or higher in certain cases. This quality makes steel wire mesh suitable for various industries, including aerospace, automotive, construction, and manufacturing, where it may encounter extreme heat or fluctuating temperature conditions. Moreover, steel wire mesh is renowned for its thermal conductivity, enabling efficient heat transfer from the surface, making it valuable for heat dissipation applications. In summary, steel wire mesh is a dependable and long-lasting material that can endure high temperatures, making it a favored choice in numerous industrial environments.

- Q: Is steel wire mesh suitable for mining applications?

- Steel wire mesh proves to be a fitting option for mining applications. Given the demanding nature of mining operations, materials that are both sturdy and long-lasting are often necessary, and steel wire mesh meets these criteria. It can withstand the harsh conditions and heavy loads frequently encountered in mining environments. When it comes to mining, steel wire mesh offers great flexibility and can be employed for an array of tasks, including controlling ventilation, supporting roofs, stabilizing the ground, and screening. It provides the necessary structural support to prevent the collapse of underground tunnels and shafts, thereby ensuring the safety of miners. On top of its versatility, steel wire mesh boasts excellent durability and resistance against abrasion, making it well-suited for use in areas prone to high levels of wear. It can endure the impact of falling rocks and debris, thereby safeguarding personnel and equipment from potential dangers. Moreover, steel wire mesh is cost-effective and relatively simple to install, reducing downtime during mining operations. It can also be customized to meet specific mining requirements, with options available for various mesh sizes and configurations. Considering its strength, durability, versatility, and cost-effectiveness, steel wire mesh stands as a suitable option for a wide range of mining applications.

- Q: Is steel wire mesh suitable for use in rooftop gardens?

- Rooftop gardens can benefit greatly from the use of steel wire mesh. This versatile and durable material offers numerous advantages that make it an excellent choice for this purpose. To begin with, the strength of steel wire mesh allows it to bear the weight of soil, plants, and other garden components. This is especially crucial in rooftop gardens, where the structure must support the additional load without compromising safety or stability. Additionally, steel wire mesh is highly resistant to various weather conditions, including sunlight, rain, and wind. This ensures that it remains sturdy and functional over time, making it ideal for rooftop gardens that are constantly exposed to the elements. Moreover, steel wire mesh serves as a reliable support system for climbing plants. It can be installed vertically to create trellises or frames for plants to grow and climb upon, enhancing the garden's visual appeal. Furthermore, steel wire mesh is a cost-effective alternative to commonly used materials like wooden frames or concrete structures in rooftop gardens. It is also easy to install and maintain, making it a convenient choice for such projects. In conclusion, steel wire mesh is a suitable option for rooftop gardens due to its strength, durability, weather resistance, support for climbing plants, and cost-effectiveness. It provides a solid foundation for these gardens, contributing to their overall functionality and aesthetics.

- Q: Can steel wire mesh be used for green walls?

- Yes, steel wire mesh can be used for green walls. Steel wire mesh is a versatile and durable material that can provide a sturdy structure for supporting climbing plants and creating vertical gardens. It allows for proper air circulation and drainage, ensuring the health of the plants. Additionally, the strength of the steel wire mesh allows it to withstand the weight of the plants and their growth over time. It can be easily installed on walls, fences, or other structures, providing a visually appealing and functional solution for creating green walls.

- Q: Is steel wire mesh suitable for ballast or retaining walls?

- By itself, steel wire mesh is generally unsuitable for ballast or retaining walls. These types of walls necessitate materials that possess adequate strength, durability, and stability to withstand the exerted forces. Although steel wire mesh can be utilized as a reinforcing element in conjunction with other materials, such as concrete, it is not commonly employed as the primary material for ballast or retaining walls. Regarding ballast walls, which serve to support tracks or roadbeds, crushed stone or gravel are commonly employed materials. These substances offer stability, drainage, and ensure the proper distribution of load and forces. On the other hand, retaining walls are designed to hold back soil or other materials and require materials with high structural integrity. Steel wire mesh alone may not possess the necessary strength and stability to support the lateral pressure imposed by the retained material. However, steel wire mesh can be employed as a reinforcement within a retaining wall structure, typically in combination with concrete or other materials, to enhance its strength and stability. In conclusion, while steel wire mesh can contribute to the construction of ballast or retaining walls as a reinforcing material, it is generally unsuitable as the primary material for these structures due to its limited strength and stability.

- Q: Can steel wire mesh be used for sports field fencing?

- Yes, steel wire mesh can be used for sports field fencing. Steel wire mesh is a durable and strong material that provides excellent security and visibility, making it suitable for sports field fencing applications. It can effectively contain players and spectators while allowing clear visibility of the game. Additionally, steel wire mesh is resistant to weather conditions and wear, ensuring a long-lasting fencing solution for sports fields.

- Q: Is steel wire mesh resistant to chemicals?

- Yes, steel wire mesh is generally resistant to chemicals. Steel is a highly durable and strong material, and when it is used to make wire mesh, it can withstand the effects of many chemicals. Steel wire mesh is commonly used in industrial and commercial applications where it may come into contact with various chemicals such as acids, alkalis, solvents, and corrosive substances. The chemical resistance of steel wire mesh depends on the specific type and grade of steel used, as well as the concentration and duration of exposure to the chemicals. In some cases, certain chemicals may cause corrosion or degradation of the steel wire mesh over time, but overall, steel wire mesh is considered to have good chemical resistance compared to other materials. It is always recommended to consult the manufacturer or supplier for specific information regarding the chemical resistance of steel wire mesh in your intended application.

- Q: Is steel wire mesh suitable for use in solar panel installations?

- Yes, steel wire mesh is suitable for use in solar panel installations. Steel wire mesh is a versatile and durable material that offers several benefits in solar panel installations. Firstly, steel wire mesh provides structural support and stability to the solar panel system. It helps to distribute the weight of the panels evenly, which is crucial for their long-term performance and durability. The strength of steel wire mesh ensures that the panels can withstand various environmental conditions, such as wind, snow, and hail, without compromising their integrity. Secondly, steel wire mesh can act as a protective barrier for the solar panels. It helps to prevent damage caused by debris, animals, or vandalism, ensuring that the panels remain intact and fully functional. Steel wire mesh can be designed to have a specific mesh size, which is small enough to keep out unwanted objects but large enough to allow sunlight to pass through. Additionally, steel wire mesh is cost-effective compared to other materials commonly used in solar panel installations. It is readily available and relatively affordable, making it a practical choice for both residential and commercial solar projects. Moreover, steel wire mesh requires minimal maintenance, reducing long-term costs associated with repairs or replacements. However, it is important to note that steel wire mesh should be properly installed and secured to ensure its effectiveness. It is recommended to consult with a professional solar panel installer to determine the specific requirements and best practices for using steel wire mesh in a solar panel installation.

- Q: What are the different edge finishing options available for steel wire mesh?

- There are several edge finishing options available for steel wire mesh, depending on the specific requirements and applications. These options include: 1. Selvage Edge: This is the most common and cost-effective edge finishing option. It involves the wire ends being twisted together to form a loop or hook, which helps to prevent unraveling and provides additional strength to the mesh. 2. Welded Edge: In this finishing method, the wire ends are welded together using heat and pressure. This creates a strong and durable edge that prevents fraying and unraveling. Welded edges are commonly used in industrial applications where high strength and stability are required. 3. Serged Edge: This edge finishing option involves wrapping the wire ends with a separate wire or thread, which is stitched along the edge of the mesh. Serged edges provide added reinforcement and can help to prevent the mesh from unraveling or becoming damaged. 4. Folded Edge: This method involves folding the wire ends back onto the mesh itself, creating a clean and smooth edge. Folded edges are commonly used in applications where aesthetics and a neat appearance are important. 5. PVC Coating: Some steel wire meshes can be coated with PVC (Polyvinyl Chloride) to provide a protective and decorative edge finish. The PVC coating not only enhances the appearance of the mesh but also helps to prevent corrosion and rusting. 6. Hemmed Edge: This finishing option involves folding the wire ends back onto themselves and then stitching or hemming them together. Hemmed edges provide added strength and prevent the mesh from fraying or unraveling. It is important to consider the specific requirements of the application, such as strength, durability, aesthetics, and budget, when selecting the appropriate edge finishing option for steel wire mesh.

Send your message to us

High Quality Stainless Steel Wire Mesh Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords