Oil Casing and Casing Pipe API-5CT,J/K55, N80, L80/P110

- Loading Port:

- Baoshan Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Best quality of Oil Casing and Casing Pipe API-5CT,J/K55, N80, L80/P110 with good price .

Seamless steel tubes can be used for a wide range transferring of oil, gas, and mine liquid, construction projects, chemical industry, power plant, Offshore platform etc.And the tubes are suitable cold bending and for galvanizing at customers request.

Specification of Oil Casing and Casing Pipe API-5CT,J/K55, N80, L80/P110,

Standard: APL SPEC 5CT

Length

|

|

(Range 1) |

(Pange 2) |

(Pange 3) |

|

Tubing |

6.10-7.32m |

8.53-9.75m |

11.58-12.80m |

|

Casing |

4.88-7.62m |

7.62-10.36m |

10.36-14.63m |

|

Pup Joint |

0.5m-6.0m(2FEET-20FEET) | ||

Chemical Composition (%)

|

Grade |

Chemical Composition% | ||||||||||||

|

C |

Mn |

Mo |

Cr |

Nl |

Cu |

P |

S |

Si | |||||

|

min |

max |

min |

max |

min |

max |

min |

max |

max |

max |

max |

max |

Max | |

|

J55 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

K55 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

N80-1 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

N80Q |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

|

M65 |

- |

0.43 |

- |

1.90 |

- |

- |

- |

- |

0.25 |

0.35 |

0.030 |

0.030 |

0.45 |

|

L80-1 |

- |

0.35 |

- |

1.00 |

0.25 |

0.75 |

- |

1.2 |

0.99 |

- |

0.020 |

0.010 |

- |

|

C90-1 |

- |

0.50 |

- |

1.90 |

- |

NL |

- |

NL |

0.99 |

- |

0.030 |

0.010 |

- |

|

C90-2 |

- |

0.45 |

- |

1.90 |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

0.45 |

|

C95 |

- |

0.35 |

- |

1.20 |

0.25 |

0.85 |

0.40 |

1.50 |

0.99 |

- |

0.020 |

0.010 |

- |

|

T95-1 |

- |

0.50 |

- |

1.90 |

- |

- |

- |

- |

0.99 |

- |

0.030 |

0.010 |

- |

|

T95-2 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.45 |

|

P110 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.45 |

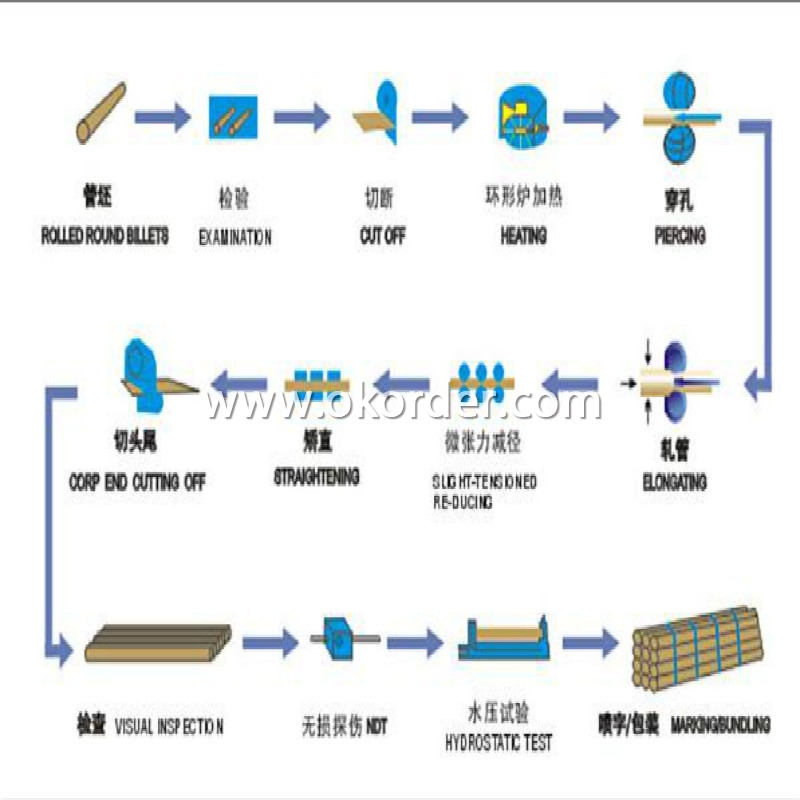

Picturers of Oil Casing and Casing Pipe API-5CT,J/K55, N80, L80/P110

Advanced production line.

Stock at warehouse.

Production process.

Our products are exported to South and East Asia, Middle East, Europe and American, and enjoyed a good reputation ,we are a well-known manufacturer of seamless steel tubes in China. Steel tubes suitable for seamless and threading are manufactured according to standard ASME B36 10, ASTM A106/A53, API 5L/5CT, DIN.

Welcome to visit us for more information and order Oil Casing and Casing Pipe API-5CT,J/K55, N80, L80/P110.

- Q: What is the role of steel pipes in the mining and extraction of minerals?

- Steel pipes play a crucial role in the mining and extraction of minerals. They are widely used in various mining operations to transport water, slurry, and other fluids, as well as to provide structural support and ventilation in underground mines. One of the primary uses of steel pipes in mining is for transporting water or slurry. Water is essential in the mining process for various purposes, such as dust suppression, ore processing, and site rehabilitation. Steel pipes are used to create a network of pipelines that transport water from a source, such as a dam or reservoir, to different areas within the mine site. Similarly, slurry, a mixture of water and crushed minerals, is often transported through steel pipes to processing plants or tailings dams. Steel pipes also play a critical role in providing structural support in underground mines. Underground mining operations require tunnels and shafts to access valuable mineral deposits. These tunnels and shafts need to be reinforced to withstand the immense pressure exerted by the surrounding rock and prevent collapses. Steel pipes are used as support structures, such as roof bolts and rock bolts, to reinforce the walls and roofs of these underground excavations, ensuring the safety of miners and the stability of the mine structure. Additionally, steel pipes are used for ventilation systems in underground mines. Proper ventilation is vital in mining to ensure a constant supply of fresh air, remove harmful gases, and control temperature and humidity levels. Steel pipes are used to create ventilation shafts and ducts that facilitate the flow of air throughout the mine. This helps maintain a safe and healthy working environment for miners by preventing the buildup of toxic gases, dust, and heat. In summary, steel pipes are indispensable in the mining and extraction of minerals. They are used for transporting water, slurry, and other fluids, providing structural support in underground mines, and facilitating ventilation systems. Without steel pipes, the efficient and safe extraction of minerals from mines would be significantly hindered.

- Q: How do you determine the pipe schedule for steel pipes?

- The pipe schedule for steel pipes is determined based on several factors including the pressure rating, wall thickness, and outer diameter of the pipe. The pipe schedule is a standardized system used to classify the thickness of pipe walls, and it helps ensure compatibility and safety in various applications. To determine the pipe schedule for steel pipes, you need to consider the maximum pressure the pipe will be subjected to. This is usually expressed in pounds per square inch (psi) or bars. The pressure rating of a pipe indicates the maximum pressure it can withstand without failure or leakage. The higher the pressure rating, the thicker the pipe walls need to be. The wall thickness of the pipe is another important factor in determining the pipe schedule. It is typically expressed in inches or millimeters. The wall thickness is directly related to the pressure rating, as thicker walls can handle higher pressures. The American National Standards Institute (ANSI) provides a set of standard wall thicknesses for steel pipes known as the "pipe schedule." The outer diameter of the pipe is also considered when determining the pipe schedule. The outer diameter can vary depending on the specific application and requirements. It is important to choose a pipe with the appropriate outer diameter to ensure proper fit and compatibility with fittings, valves, and other components. In summary, the pipe schedule for steel pipes is determined by considering the maximum pressure, wall thickness, and outer diameter. By matching these factors with the appropriate pipe schedule, you can ensure that the steel pipe will be suitable for its intended use and capable of withstanding the required pressure.

- Q: Are steel pipes resistant to vibration?

- Yes, steel pipes are generally resistant to vibration due to their inherent strength and rigidity. However, the level of resistance can vary depending on factors such as pipe thickness, design, and installation. Additionally, the presence of external factors like fluid flow or mechanical forces can also affect the level of vibration resistance.

- Q: How are steel pipes used in the manufacturing of food processing machinery and equipment?

- Steel pipes are commonly used in the manufacturing of food processing machinery and equipment due to their durability, corrosion resistance, and high strength. These pipes are used for various purposes such as fluid transportation, steam generation, and structural support in the machinery. They are also crucial for conveying liquids, gases, and other food ingredients safely and hygienically throughout the manufacturing process. Additionally, steel pipes can withstand high temperatures and pressures, making them ideal for applications like sterilization, pasteurization, and cooking in food processing machinery.

- Q: Can steel pipes be used for aboveground applications?

- Steel pipes have the capability to be utilized in aboveground applications. Their strength, durability, and resistance to corrosion are well-known attributes, making them suitable for a variety of aboveground uses. Industries such as construction, oil and gas, water transportation, and infrastructure development often rely on steel pipes. Aboveground applications for steel pipes include structural supports, handrails, fencing, scaffolding, outdoor pipelines, and various other outdoor structures. Furthermore, steel pipes can undergo coating or painting processes to provide additional protection against weather conditions and enhance their aesthetic appearance. All in all, steel pipes offer versatility for aboveground applications due to their dependable nature and long-lasting performance.

- Q: What are the environmental impacts of using steel pipes?

- The environmental impacts of using steel pipes include the extraction and processing of raw materials, energy consumption during manufacturing, and carbon emissions. Additionally, the disposal of steel pipes can contribute to landfill waste. However, steel pipes are highly durable, recyclable, and have a long lifespan, which mitigates some of these negative impacts.

- Q: How are steel pipes used in the construction of coal-fired power plants?

- Steel pipes are commonly used in the construction of coal-fired power plants for various purposes. They are utilized for transporting coal and other fuels, as well as for carrying water and steam in the power generation process. Steel pipes are also used in the construction of the plant's cooling system, helping to circulate water and dissipate heat. Additionally, they are employed in the construction of the plant's exhaust system, facilitating the removal of combustion byproducts. In summary, steel pipes play a crucial role in the infrastructure of coal-fired power plants, enabling efficient fuel transportation, heat exchange, and waste management.

- Q: Where is a steel pipe casing usually used?

- A straight tube of carbon steel sheathed on pipes and tubes and threading tubes to protect the joints from damage by electric welding. The purpose is to protect the wires and cables.

- Q: What are the different methods of pipe joining using steel pipes?

- There are multiple ways to connect steel pipes, each with its own pros and cons. 1. Threaded and coupled: This method includes threading the ends of the steel pipes and using couplings to connect them. It is a cost-effective option, but not suitable for high-pressure or gas applications. 2. Welding: Welding is a popular choice for joining steel pipes. It involves heating the pipe ends and fusing them together through welding. This method creates a strong and leak-proof joint, but it requires skilled labor and can be time-consuming. 3. Grooved: This method involves grooving the ends of the steel pipes and connecting them using mechanical couplings or fittings. It is a reliable and fast option suitable for both high and low-pressure applications, but it requires specialized tools and equipment. 4. Flanged: Flanged joints connect steel pipes using flanges, which are discs with bolt holes. The pipes are aligned and bolted together with gaskets to ensure a secure connection. This method is commonly used for large pipes and high-pressure applications, but it can be expensive and time-consuming to install. 5. Compression: Compression fittings are used to join steel pipes by compressing a ferrule or sleeve against the pipe. This method is quick, easy, and doesn't require special tools. However, it is not suitable for high-pressure or high-temperature applications. 6. Brazing: Brazing involves heating the pipe ends and melting a filler material between them to create a joint. It is a reliable method for HVAC and refrigeration systems, but it requires skilled labor and precise temperature control. When selecting the appropriate method for joining steel pipes, it is crucial to consider the specific requirements of the application, such as pressure, temperature, and material compatibility.

1. Manufacturer Overview

| Location | Shanghai China |

| Year Established | 1999 |

| Annual Output Value | Above Thirty Million RMB |

| Main Markets | Main land;Middle East; Southeast Asia |

| Company Certifications | ISO 9001:2010;API 5L |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Baoshan |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 300-500 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Oil Casing and Casing Pipe API-5CT,J/K55, N80, L80/P110

- Loading Port:

- Baoshan Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords