Stainless Steel Sheet With Competitive Price In Our Stockwarehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

There are many different grades, such as: 200 series, 300 series, 400 series, 900series, etc. The detailed grade are as follows: 201, 202, 301, 304, 316, 410, 420, 430, etc.

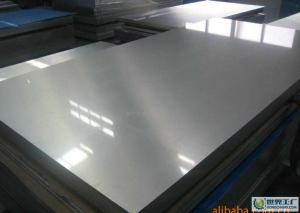

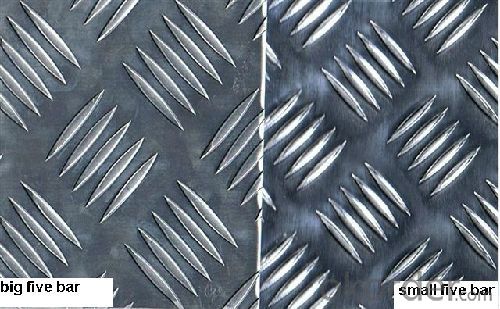

The surface is including 2B, BA, Mirror Finish, Checkered, etc.

If you are interested in it, please feel free to contact us, so that i can quote you price in earliest time.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 3 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are stainless steel sheet, stainless steel coil, stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: How are stainless steel sheets installed?

- Stainless steel sheets are typically installed using a few different methods, depending on the specific application and requirements. Here are some common installation methods for stainless steel sheets: 1. Adhesive: One of the simplest and most common methods is using an adhesive to bond the stainless steel sheet to the desired surface. An adhesive specifically designed for stainless steel is applied to the back of the sheet, which is then pressed firmly onto the surface. This method works well for flat or slightly curved surfaces and provides a clean and seamless installation. 2. Mechanical fasteners: For applications where additional strength and stability are required, stainless steel sheets can be installed using mechanical fasteners such as screws, bolts, or rivets. These fasteners are drilled or screwed through the sheet and into the surface to secure it in place. This method is commonly used for installations that need to withstand external forces or for attaching stainless steel sheets to structural components. 3. Welding: In some cases, particularly for large or complex installations, welding may be used to connect stainless steel sheets together or to other metal structures. Welding creates a strong and permanent bond between the sheets, ensuring a secure installation. However, this method requires skilled professionals and specialized equipment to ensure proper welding techniques and prevent damage to the stainless steel. 4. Magnetic attachment: Some stainless steel sheets are designed with a magnetic backing, allowing them to be easily attached to magnetic surfaces. This method is quick and convenient, as the sheets can be easily repositioned or removed if needed. However, it is important to ensure that the magnetic surface is clean and free from debris that could affect the adhesion. Before installing stainless steel sheets, it is crucial to properly prepare the surface by cleaning it thoroughly and removing any dirt, dust, or grease. This will help ensure a secure and long-lasting installation. Additionally, following the manufacturer's instructions and guidelines for the specific stainless steel sheet being installed is essential to achieve the best results.

- Q: Can stainless steel sheets be used for decorative wall panels?

- Yes, stainless steel sheets can be used for decorative wall panels. Their sleek and modern appearance, durability, and resistance to corrosion make them a popular choice for adding a decorative touch to walls in various settings such as homes, offices, restaurants, or commercial spaces.

- Q: Are stainless steel sheets suitable for automotive exhaust systems?

- Yes, stainless steel sheets are suitable for automotive exhaust systems. Stainless steel is a preferred material for exhaust systems due to its high resistance to corrosion, heat, and vibration. It can withstand the high temperatures and harsh conditions that exhaust systems are exposed to, making it a durable and long-lasting choice. Additionally, stainless steel has excellent thermal conductivity, which helps in dissipating heat efficiently. It also offers good formability, allowing manufacturers to design and shape the exhaust components as needed. Overall, stainless steel sheets are a reliable and popular choice for automotive exhaust systems.

- Q: Are stainless steel sheets suitable for welding or fabrication?

- Yes, stainless steel sheets are suitable for welding and fabrication. Stainless steel has excellent weldability, which means it can be easily fused together using various welding techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. It also has good formability, allowing it to be easily shaped and fabricated into different structures or components. Additionally, stainless steel sheets offer high strength and corrosion resistance, making them a popular choice in industries such as construction, automotive, and manufacturing. Overall, stainless steel sheets are a versatile and reliable material for welding and fabrication applications.

- Q: What are the benefits of using brushed stainless steel sheets?

- Using brushed stainless steel sheets has several advantages. To begin with, their sleek and attractive appearance makes them a popular choice for appliances, countertops, and backsplashes. The brushed finish adds a unique texture and matte appearance, bringing sophistication to any space. Additionally, brushed stainless steel sheets are highly durable and resistant to corrosion, making them suitable for indoor and outdoor use. They can withstand harsh conditions such as chemicals, moisture, and extreme temperatures. Moreover, their brushed finish helps to hide fingerprints, smudges, and scratches, making them easy to clean and maintain. Furthermore, brushed stainless steel sheets are hygienic and inhibit bacteria growth, making them ideal for the food and medical industries. Their smooth surface allows for easy cleaning and disinfection, ensuring a safe and sanitary environment. Moreover, these sheets offer excellent longevity and are a cost-effective investment. They resist wear and tear, maintaining their appearance for many years without the need for replacement. Lastly, brushed stainless steel sheets are versatile and can be customized to fit different design preferences. They can be easily cut, shaped, and formed into various sizes and shapes, allowing for endless design possibilities. Whether you prefer a modern, industrial look or a more traditional and elegant style, brushed stainless steel sheets can be tailored to meet your specific needs. In conclusion, the use of brushed stainless steel sheets offers benefits such as an attractive appearance, durability, corrosion resistance, hygienic properties, longevity, and versatility. Whether used in residential, commercial, or industrial settings, these sheets provide a wide range of advantages, making them a popular choice for various applications.

- Q: Are stainless steel sheets suitable for food storage containers?

- Food storage containers made from stainless steel sheets are a suitable option. Many people prefer stainless steel for food storage containers because it offers numerous advantages. To begin with, stainless steel is non-reactive, meaning it doesn't interact with or release any harmful chemicals into the food, thus maintaining its taste and quality. Moreover, stainless steel is resistant to corrosion, rust, and staining, making it a durable and long-lasting material for food storage containers. It is also effortless to clean and maintain as it doesn't absorb any odors or flavors from previously stored food items. Additionally, stainless steel is hygienic since it doesn't harbor bacteria or other pathogens, ensuring the safety and healthiness of your food. In conclusion, stainless steel sheets are an excellent choice for food storage containers due to their suitability for food contact, durability, and hygienic properties.

- Q: What are the different surface textures available for stainless steel sheets?

- Stainless steel sheets come in a variety of surface textures to meet different aesthetic and functional requirements. Some of the common surface textures available for stainless steel sheets are: 1. No. 1 Finish: This is the most common surface texture, also known as mill finish. It has a smooth, reflective surface that is obtained by hot rolling the stainless steel sheet. 2. No. 2B Finish: This surface texture is achieved through a process called cold rolling and annealing. It has a slightly matte appearance with a smooth, non-reflective finish. 3. No. 4 Finish: Also known as brushed or satin finish, this surface texture is obtained by mechanically polishing the stainless steel sheet. It has a brushed appearance with fine parallel lines, providing a textured and decorative finish. 4. No. 8 Finish: This surface texture, also referred to as mirror or reflective finish, is achieved by polishing the stainless steel sheet to a high shine. It has a glossy, mirror-like appearance that reflects light and adds a luxurious touch to applications. 5. Embossed Finish: This surface texture involves impressing a pattern or design onto the stainless steel sheet. It can range from simple textures like diamond or linen patterns to more intricate designs, providing both visual interest and improved grip for certain applications. 6. Bead Blast Finish: This surface texture is created by blasting the stainless steel sheet with fine glass beads or other abrasives. It produces a uniform, matte finish with a slightly roughened texture, suitable for applications where a subdued appearance is desired. 7. Etched Finish: This surface texture involves chemically etching the stainless steel sheet to create patterns or designs. It can produce intricate and detailed textures, offering a unique and artistic finish. These are just a few examples of the different surface textures available for stainless steel sheets. Each texture has its own distinct characteristics, allowing for a range of design possibilities in various industries such as architecture, interior design, automotive, and more.

- Q: Can stainless steel sheets be used in marine environments?

- Yes, stainless steel sheets can be used in marine environments. Stainless steel is highly resistant to corrosion, making it suitable for marine applications where it will be exposed to saltwater and high humidity. It is commonly used in marine vessels, offshore platforms, and other structures that require durability and resistance to rust and corrosion.

- Q: Can stainless steel sheets be used for elevator shafts?

- Elevator shafts can indeed utilize stainless steel sheets, as they offer durability, resistance to corrosion, and an appealing aesthetic. By employing stainless steel sheets, one can ensure a lasting and easy-to-maintain solution, as they resist rust and corrosion caused by factors like humidity, moisture, and chemicals. Moreover, stainless steel possesses strength and can withstand the weight and stress typically encountered by elevator shafts. The sleek and contemporary look of stainless steel further enhances the overall design value of the elevator shaft. Consequently, stainless steel sheets serve as a dependable and fitting material choice for constructing elevator shafts.

- Q: What is the fatigue strength of stainless steel sheets?

- The fatigue strength of stainless steel sheets can vary depending on various factors such as the specific grade of stainless steel, the manufacturing process, the surface finish, and the testing conditions. Generally, stainless steel sheets exhibit high fatigue strength due to their inherent properties, such as the ability to withstand cyclic loading and resistance to corrosion. The fatigue strength of stainless steel sheets is typically expressed in terms of stress amplitude (σa) or stress range (σr) that the material can withstand for a specific number of cycles before failure. It is often determined through fatigue testing, which involves subjecting the material to repeated cyclic loading until failure occurs. The number of cycles required to cause failure is known as the fatigue life. Different grades of stainless steel have different fatigue strengths, with higher grades typically exhibiting higher fatigue resistance. For instance, austenitic stainless steels such as 304 and 316 have excellent fatigue strength and are commonly used in applications where cyclic loading is prevalent, such as structural components and automotive parts. The fatigue strength of stainless steel sheets can also be influenced by surface finish. Poor surface conditions, such as scratches, notches, or roughness, can act as stress concentrators and reduce the fatigue strength. Therefore, it is important to ensure that stainless steel sheets have a smooth and defect-free surface to maximize their fatigue resistance. Moreover, the fatigue strength of stainless steel sheets can be affected by environmental factors such as temperature, humidity, and corrosive media. Elevated temperatures and aggressive environments can reduce the fatigue life of stainless steel, so it is crucial to consider these factors when designing for fatigue resistance. In conclusion, the fatigue strength of stainless steel sheets is generally high due to their inherent properties. However, it can vary depending on factors such as grade, surface finish, and environmental conditions. Conducting fatigue testing and considering these factors during the design process can help ensure the optimal performance and durability of stainless steel sheets in cyclic loading applications.

Send your message to us

Stainless Steel Sheet With Competitive Price In Our Stockwarehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords