Stainless Steel Sheet With Best Price Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 kg

- Supply Capability:

- 2000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

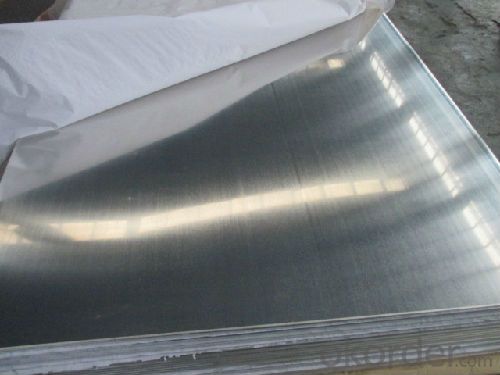

1.Structure of Product Description

Cold rolled Stainless steel sheet is widely used in the field of construction field and decoration field, etc. There are many different grades, such as: 200 series, 300 series, 400 series, 900series, etc. The detailed grade are as follows: 201, 202, 301, 304, 316, 410, 420, 430, etc.

The surface is including 2B, BA, Mirror Finish, Checkered, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 3 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally UAE, FRANCE, USA, BANGLADESH, ETC.

---Normally they are stainless steel sheet, stainless steel coil, stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: What are the different types of stainless steel sheet edges?

- Stainless steel sheets come in three main types of edges: mill edge, slit edge, and deburred edge. 1. The mill edge is the most common type and is produced during manufacturing. It has a rough, unfinished edge that is typically straight and perpendicular to the sheet's surface. It is suitable for applications where a smooth edge is not necessary. 2. Slit edge sheets are created by cutting large rolls of stainless steel into narrower widths. These edges are smoother and more precise compared to the mill edge. They are commonly used in applications that require a polished and precise edge, such as architectural finishes or fabrication processes. 3. A deburred edge is achieved by removing any sharp or rough edges from the stainless steel sheet. This is done to improve safety during handling or installation. Deburring can be done through grinding, sanding, or using specialized tools. The resulting edge is smooth and free from burrs or sharp protrusions. It's important to consider the specific application and requirements when choosing the edge type for a stainless steel sheet. Each type has its own advantages and limitations, and factors like aesthetics, functionality, and safety should be taken into account when selecting the appropriate edge for a project.

- Q: What are the different types of stainless steel sheet coatings available?

- A variety of stainless steel sheet coatings are available, each with its own unique properties and benefits. Some commonly used coatings include: 1. Galvanized Coatings: These coatings protect stainless steel sheets from corrosion and rust by applying a layer of zinc. They are ideal for outdoor applications or environments with moisture or chemicals. 2. Powder Coatings: Offering excellent durability and corrosion resistance, powder coatings are a popular choice. They are applied as a dry powder and heated to form a protective layer. They come in various colors and finishes for customization. 3. Electroplating: This process involves depositing a thin layer of another metal, such as chrome, nickel, or zinc, onto the stainless steel sheet. It enhances appearance and improves resistance to corrosion and wear. 4. PVD Coatings: Physical Vapor Deposition (PVD) coatings are created by depositing a thin film onto the stainless steel sheet using a vacuum process. They offer improved hardness, scratch resistance, and color options, making them suitable for architectural or decorative purposes. 5. Organic Coatings: Paints or lacquers can be applied as organic coatings to provide an extra layer of corrosion protection and aesthetic choices. They are commonly used when color matching or branding is important. Each stainless steel sheet coating has its own advantages and is suitable for specific applications. The choice of coating depends on factors such as intended use, desired appearance, and environmental conditions. It is important to carefully consider these factors and seek expert advice to select the most suitable coating for your needs.

- Q: What are the common applications for stainless steel sheets?

- Due to their exceptional properties and durability, stainless steel sheets find a wide range of applications. They are utilized in various industries for different purposes. Some of the common uses include: 1. Architectural purposes: Stainless steel sheets are commonly employed in architectural projects like cladding, roofing, and wall panels. They not only provide a sleek and modern appearance to buildings but also offer corrosion resistance and easy maintenance. 2. Kitchenware manufacturing: Stainless steel sheets are widely used in the production of kitchen appliances, sinks, countertops, and cookware. Their resistance to stains, heat, and corrosion makes them ideal for use in kitchens. 3. Automotive industry: Stainless steel sheets are extensively utilized in the automotive sector for manufacturing exhaust systems, body parts, and trim. They provide strength, corrosion resistance, and an attractive finish, making them suitable for both functional and aesthetic purposes. 4. Medical equipment production: Stainless steel sheets are commonly employed in the manufacturing of medical equipment and instruments. This is due to their hygienic properties, resistance to corrosion, and staining. They are used in surgical instruments, dental tools, hospital equipment, and implants. 5. Chemical and petrochemical industries: The chemical and petrochemical industries extensively use stainless steel sheets due to their resistance to high temperatures, chemicals, and corrosion. They are employed in storage tanks, pipelines, heat exchangers, and other equipment that comes into contact with corrosive substances. 6. Food processing industry: Stainless steel sheets are highly sought after in the food processing industry because of their hygienic properties and resistance to corrosion. They are used to create food preparation surfaces, storage containers, and machinery that must meet strict sanitary standards. 7. Construction projects: Stainless steel sheets are used in construction projects such as bridges, tunnels, and railway tracks due to their strength, durability, and resistance to corrosion. They are also utilized in the construction of industrial buildings, warehouses, and infrastructure. 8. Aerospace industry: Stainless steel sheets find applications in the aerospace industry for various components, including aircraft frames, engine parts, and interior fittings. They offer an excellent strength-to-weight ratio, corrosion resistance, and heat resistance, making them suitable for demanding aerospace applications. In conclusion, stainless steel sheets are a versatile and widely used material in various industries due to their exceptional properties. They are indispensable for many applications.

- Q: What are the different types of stainless steel sheet finishes for pharmaceutical applications?

- Some of the different types of stainless steel sheet finishes for pharmaceutical applications include 2B finish, 2D finish, BA finish, and mirror finish.

- Q: Can stainless steel sheets be used for architectural column covers?

- Yes, stainless steel sheets can be effectively used for architectural column covers due to their durability, strength, and aesthetic appeal. Stainless steel offers excellent corrosion resistance and can withstand various weather conditions, making it a suitable material for outdoor applications. Additionally, stainless steel sheets can be customized to achieve different finishes and designs, providing architects and designers with flexibility in creating visually appealing column covers.

- Q: What are the bending limits of stainless steel sheets?

- The bending limits of stainless steel sheets are contingent upon several factors, including the stainless steel grade, sheet thickness, and the specific bending process employed. Stainless steel sheets are renowned for their exceptional strength and durability, enabling them to be bent to a certain degree without fracturing or breaking. As a general rule, stainless steel sheets can be bent to a radius that is at least twice the thickness of the sheet. For instance, a 1mm thick sheet can typically be bent to a minimum radius of 2mm. It is crucial to note, however, that this is merely a general guideline, and the actual bending limits may differ based on the particular stainless steel grade. Certain stainless steel grades, such as 304 and 316, possess higher yield strengths and greater resistance to deformation, rendering them suitable for more demanding bending applications. Thicker sheets also exhibit higher bending limits in comparison to thinner ones, as they possess more material to withstand the forces of bending. Moreover, it is important to mention that the chosen bending process can impact the bending limits of stainless steel sheets. Press brake bending and roll bending are commonly employed methods for bending stainless steel sheets. These processes employ distinct techniques and equipment, resulting in varying bending limits. To ascertain the exact bending limits for a specific stainless steel sheet grade and thickness, it is advisable to refer to the manufacturer's specifications or seek guidance from a professional metal fabricator. They possess the expertise and knowledge to provide precise information and guidance on the bending capabilities of stainless steel sheets tailored to your specific application.

- Q: Are stainless steel sheets resistant to hydrogen embrittlement?

- Stainless steel sheets are commonly resistant to hydrogen embrittlement. Hydrogen embrittlement refers to the brittleness and susceptibility to cracking caused by the diffusion of hydrogen atoms into the metal structure. Nonetheless, stainless steel has a strong resistance to hydrogen embrittlement due to its distinct composition and microstructure. The presence of chromium in stainless steel produces a protective oxide layer on the surface, acting as a barrier against hydrogen diffusion. Furthermore, stainless steel sheets are often alloyed with elements like nickel and molybdenum, further enhancing their resistance to hydrogen embrittlement. However, it is important to note that certain conditions, such as high temperatures or high levels of hydrogen exposure, can still potentially result in hydrogen embrittlement in stainless steel. Hence, it is crucial to consider the specific application and operating conditions when determining the suitability of stainless steel sheets in relation to hydrogen embrittlement.

- Q: What are the different types of stainless steel sheets available?

- There are several different types of stainless steel sheets available in the market, each with its own unique properties and applications. Some of the most common types include: 1. Austenitic Stainless Steel Sheets: This type of stainless steel is the most widely used and offers excellent corrosion resistance, high strength, and good formability. It is commonly used in kitchen equipment, food processing plants, and pharmaceutical industries. 2. Ferritic Stainless Steel Sheets: Ferritic stainless steel sheets have a higher chromium content and lower carbon content compared to austenitic stainless steel. They are known for their excellent resistance to stress corrosion cracking and are often used in automotive applications, architectural structures, and appliances. 3. Martensitic Stainless Steel Sheets: Martensitic stainless steel sheets have a higher carbon content compared to other types, which gives them high strength and hardness. They are commonly used in applications requiring wear resistance, such as cutlery, surgical instruments, and turbine blades. 4. Duplex Stainless Steel Sheets: Duplex stainless steel sheets have a mixed microstructure of austenite and ferrite, which provides them with a combination of high strength and excellent corrosion resistance. They are often used in chemical processing plants, oil and gas industries, and marine environments. 5. Precipitation Hardening Stainless Steel Sheets: Precipitation hardening stainless steel sheets are heat-treatable and offer high strength and corrosion resistance. They are commonly used in aerospace applications, defense equipment, and high-performance industries. It's important to consider the specific requirements of your project or application when choosing the type of stainless steel sheet, as each type has its own set of properties and advantages.

- Q: How do I prevent stress corrosion cracking on stainless steel sheets?

- To prevent stress corrosion cracking on stainless steel sheets, you can follow a few key steps. First, ensure that the stainless steel is properly cleaned and free from any contaminants that may promote corrosion. Additionally, avoid exposing the stainless steel sheets to environments with high chloride concentrations or acidic substances as they can accelerate stress corrosion cracking. It is also important to reduce any residual stresses in the material by utilizing proper fabrication techniques and avoiding excessive cold working. Finally, selecting the appropriate stainless steel grade for the specific application, such as those with improved resistance to stress corrosion cracking, can greatly help in preventing this type of corrosion.

- Q: Are stainless steel sheets suitable for heat exchangers?

- Yes, stainless steel sheets are suitable for heat exchangers. Stainless steel has excellent thermal conductivity, which means it can efficiently transfer heat between fluids. Additionally, stainless steel is highly resistant to corrosion and oxidation, making it ideal for applications where it will come into contact with various fluids or gases at different temperatures. Its durability and ability to withstand high temperatures also make it a reliable choice for heat exchangers. Overall, stainless steel sheets are a popular and reliable material for heat exchangers due to their thermal conductivity, corrosion resistance, and durability.

Send your message to us

Stainless Steel Sheet With Best Price Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4 kg

- Supply Capability:

- 2000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords