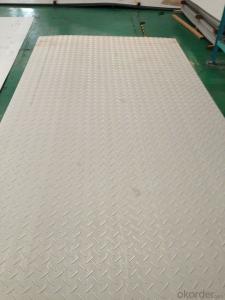

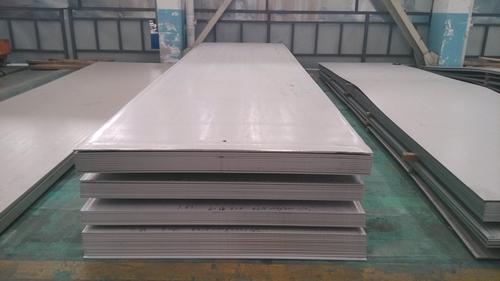

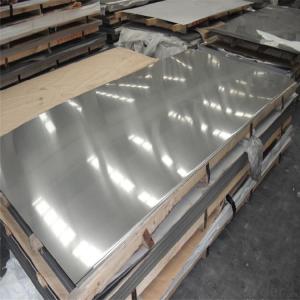

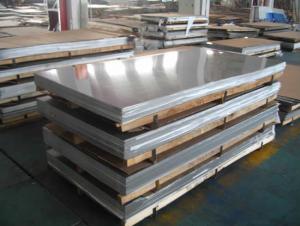

Stainless Steel 304 sheet with highest standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q: Can stainless steel pipes be used for underground gas pipelines?

- Yes, stainless steel pipes can be used for underground gas pipelines. Stainless steel is highly resistant to corrosion, making it an ideal material for underground applications where the pipes come into contact with moisture, soil, and other corrosive elements. Additionally, stainless steel has excellent mechanical properties, such as high tensile strength and durability, which make it suitable for withstanding the underground conditions and the pressure requirements of gas pipelines. Moreover, stainless steel pipes are known for their longevity and low maintenance requirements, making them a cost-effective choice for underground gas pipelines. Nonetheless, it is essential to follow industry standards and regulations, as well as proper installation and maintenance practices, to ensure the safe and efficient operation of the gas pipelines.

- Q: Can stainless steel pipes be used in the water treatment industry?

- Yes, stainless steel pipes can be used in the water treatment industry. Stainless steel is highly resistant to corrosion, making it suitable for use in environments where water is treated and processed. It is often used in various applications within the water treatment industry, including pipelines, pumps, valves, and tanks. Stainless steel pipes offer excellent strength and durability, ensuring long-lasting performance even in harsh conditions. Additionally, stainless steel is hygienic and easy to clean, making it ideal for applications where maintaining water purity is essential. Overall, stainless steel pipes are a reliable and cost-effective choice for the water treatment industry.

- Q: Are stainless steel pipes suitable for hygienic applications?

- Indeed, hygienic applications can benefit greatly from the use of stainless steel pipes. Industries such as food processing, pharmaceuticals, and dairy heavily rely on stainless steel due to its ability to maintain cleanliness and prevent contamination. One key advantage of stainless steel is its exceptional resistance to corrosion. This is particularly significant in hygienic environments where bacteria and pathogens must be kept at bay. Stainless steel pipes demonstrate a remarkable resistance to rust and corrosion, even when exposed to various chemicals and cleaning agents commonly used in such settings. This resistance ensures the pipes' integrity and effectively prevents any contamination from occurring. Moreover, stainless steel boasts a smooth and non-porous surface, which greatly facilitates its cleaning and sanitization. This smoothness prevents the accumulation of dirt, bacteria, and other particles, thereby enabling the maintenance of a hygienic environment. Cleaning stainless steel pipes can be effortlessly accomplished using a range of methods, including steam, high-pressure water, or chemical cleaning agents. Furthermore, stainless steel is an extremely durable and long-lasting material. It can withstand high temperatures and pressures, making it suitable for an extensive array of hygienic applications. These pipes can be employed to transport fluids, gases, or other materials without compromising their hygienic properties. Additionally, stainless steel exhibits non-reactive properties, meaning it does not react with the substances it comes into contact with. This characteristic is of utmost importance in preventing any contamination or alteration of the transported substances. In conclusion, stainless steel pipes are highly appropriate for hygienic applications due to their exceptional resistance to corrosion, smooth surface, durability, and non-reactive properties. These pipes offer a dependable and hygienic solution for industries wherein cleanliness and prevention of contamination are paramount.

- Q: Can stainless steel pipes be used for pharmaceutical industries?

- Indeed, stainless steel pipes find utility within the pharmaceutical industries. Owing to its exceptional resistance to corrosion, durability, and hygienic qualities, stainless steel is widely employed in this sector. Its ability to withstand chemicals, high temperatures, and moisture renders it suitable for diverse applications throughout the pharmaceutical manufacturing processes. Stainless steel pipes frequently serve the purposes of conveying and preserving pharmaceutical products, as well as facilitating the distribution of purified water, steam, and other fluids. Moreover, stainless steel is easily cleaned and maintained, a vital aspect in guaranteeing the cleanliness and sterility mandated in pharmaceutical facilities.

- Q: What is the maximum temperature stainless steel pipes can handle?

- The maximum temperature that stainless steel pipes can handle depends on the grade of stainless steel used. Generally, stainless steel can handle temperatures ranging from 1200 to 1600 degrees Fahrenheit (650 to 870 degrees Celsius). However, it is important to consult the specific material specifications and engineering guidelines for the particular grade of stainless steel being used to determine its maximum temperature limit.

- Q: Are stainless steel pipes suitable for beer brewing applications?

- Yes, stainless steel pipes are highly suitable for beer brewing applications. Stainless steel is corrosion-resistant, ensuring the purity and quality of the beer. It also has excellent heat resistance, making it suitable for various brewing processes such as boiling and fermentation. Additionally, stainless steel is easy to clean and maintain, ensuring hygienic conditions throughout the brewing process.

- Q: How do stainless steel pipes compare to carbon fiber pipes?

- Stainless steel pipes possess distinct qualities and find usage in diverse fields. Renowned for their robustness and power, they exhibit exceptional resistance to corrosion and can withstand elevated temperatures and pressures. Consequently, they prove suitable for various industries, including oil and gas, chemical, and construction. Boasting an elongated lifespan and the ability to bear heavy loads, stainless steel pipes emerge as a reliable option for numerous applications. Nevertheless, their relatively hefty weight necessitates additional support structures. Conversely, carbon fiber pipes, characterized by their lightness and high strength-to-weight ratio, serve as an alternative. Crafted from carbon fibers embedded in a resin matrix, they yield a formidable and rigid material. Aerospace, automotive, and sports equipment industries commonly employ carbon fiber pipes. Their lightweight nature permits enhanced fuel efficiency in vehicles and augmented performance in sports equipment. However, carbon fiber pipes prove pricier than their stainless steel counterparts and may lack the desired resilience to extreme temperatures or corrosive surroundings. To summarize, stainless steel pipes excel in durability and corrosion resistance, making them well-suited for demanding tasks. Carbon fiber pipes, on the other hand, offer lightweight construction and a commendable strength-to-weight ratio, rendering them ideal for weight reduction-focused applications. Ultimately, the choice between stainless steel and carbon fiber pipes hinges on specific requirements and the trade-offs between cost, weight, and performance.

- Q: What is the difference between Schedule 5 and Schedule 10 stainless steel pipes?

- Schedule 5 and Schedule 10 stainless steel pipes are both commonly used in various industries and applications, but there are some key differences between the two. The main difference lies in their wall thickness. Schedule 5 stainless steel pipes have a thinner wall thickness compared to Schedule 10 stainless steel pipes. This means that Schedule 5 pipes have a higher internal diameter, allowing for a greater flow of fluids or gases through the pipe. Schedule 10 stainless steel pipes, on the other hand, have a thicker wall thickness, resulting in a smaller internal diameter. This makes them more suitable for applications that require higher pressure or strength, as the thicker walls provide increased durability and resistance to external forces. Additionally, the different wall thicknesses of Schedule 5 and Schedule 10 pipes affect their weight and cost. Due to the thinner walls, Schedule 5 pipes are lighter and less expensive than Schedule 10 pipes. In terms of availability, Schedule 10 stainless steel pipes are more commonly used in industrial processes that involve high pressure or corrosive environments, such as chemical plants or oil refineries. Schedule 5 stainless steel pipes are often used in applications where the flow of fluids or gases is not under extreme pressure, such as plumbing or low-pressure conveying systems. In summary, the main differences between Schedule 5 and Schedule 10 stainless steel pipes lie in their wall thickness, internal diameter, strength, weight, and cost. The choice between the two depends on the specific requirements of the application and the level of pressure or durability needed.

- Q: Are stainless steel pipes suitable for paper mills?

- Paper mills benefit greatly from the use of stainless steel pipes due to their suitability for the harsh conditions found in these facilities. With constant exposure to water, chemicals, and high temperatures, stainless steel pipes offer long-lasting durability. Their resistance to rust and corrosion ensures the integrity of the pipes, preventing leaks or contamination in the paper production process. Furthermore, stainless steel pipes are easy to clean and maintain, crucial for maintaining cleanliness and hygiene in paper mills. The smooth surface of these pipes prevents debris buildup, reducing the risk of blockages and improving material flow. In addition to their resistance to corrosion, stainless steel pipes are also strong and capable of withstanding high temperatures. This makes them ideal for the extreme conditions present in paper mills, where hot water, steam, and chemicals are frequently used. Overall, stainless steel pipes are an excellent choice for paper mills due to their corrosion resistance, cleanliness, durability, and high-temperature resistance. Their use contributes to efficient and reliable paper production processes.

- Q: Comparison of ring type connection and argon arc welding of stainless steel pipe

- Characteristics of argon arc welding of stainless steel pipe:1. Permanent structure, reliable quality;2. Reduce the number of parts used;3. The construction technology is relatively complicated.

Send your message to us

Stainless Steel 304 sheet with highest standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords