Stainless Steel Plate Sheet 304 2mm 3mm Custom Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

2mm 3mm custom thickness stainless steel plate sheet 304

We are a professional manufacturer of stainless steel sheet. According to ASTM, JIS and AISI,GB, standards, Jaway steel enhances effectiveness and of quality control from selecting the raw materials, cutting, slitting, shearing, surface treatment, packing, exporting of the existing products.

Product Description

Details of Stainless Steel Sheet/Plate: > > > > > > > > > > > > > > > > >

2mm 3mm custom thickness stainless steel plate sheet 304

Product Name: | 2mm 3mm custom thickness stainless steel plate sheet 304 cold /hot rolled |

Material: | stainless steel |

Thickness: | 0.3-120mm |

Width: | 1000mm/1219mm/1220mm/1500mm/1800mm/2000mm or as customer's requirements. |

Length: | 2000mm/2440mm/6000mm or as your requirements |

Standard: | DIN GB ISOJIS BA ASTM AISIetc. |

Garde: | 201 202 304 304l 316 316l 309s 310s 321 410 430 904l 2205 etc. |

Finish: | No.1,2B,ba,No.4,8k,BA,Hairline etc. |

Brand: | Tisco,Baosteel,Jisco |

Certification: | ISO,SGS,BV,ROHS,IBR etc. |

Application: | building, industry, machinery, elevators,doors,kitchware, hostipal,boliers,interior and out decoration, etc |

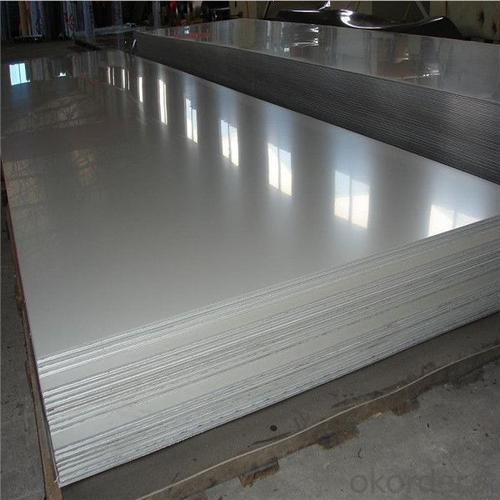

Products Show

These are the normal items, for the special requirements,we can also meet.

Surface finish | Characteristics and application |

NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

NO.3 | Polished with abrasive belt of git#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q: How do you determine the thickness of stainless steel sheets required for a specific application?

- To determine the thickness of stainless steel sheets required for a specific application, several factors need to be considered. These factors include the type and magnitude of the load or stress the sheet will be subjected to, the desired level of durability and strength, the specific application requirements, and any applicable industry standards or regulations. Engineering calculations, material testing, and consultation with experts in the field can help in determining the appropriate thickness for the stainless steel sheets needed for the specific application.

- Q: What is the maximum temperature stainless steel sheets can withstand?

- The maximum temperature stainless steel sheets can withstand depends on the specific grade of stainless steel. Generally, most stainless steel grades can withstand temperatures up to around 1500°F (815°C) before experiencing significant oxidation or scaling. However, certain high-temperature grades of stainless steel, such as 310 or 321, can withstand temperatures up to 2100°F (1150°C) or even higher. It is important to consider the specific application and grade of stainless steel when determining the maximum temperature it can withstand to ensure optimal performance and durability.

- Q: What are the different surface textures available for stainless steel sheets?

- Stainless steel sheets come in a variety of surface textures to meet different aesthetic and functional requirements. Some of the common surface textures available for stainless steel sheets are: 1. No. 1 Finish: This is the most common surface texture, also known as mill finish. It has a smooth, reflective surface that is obtained by hot rolling the stainless steel sheet. 2. No. 2B Finish: This surface texture is achieved through a process called cold rolling and annealing. It has a slightly matte appearance with a smooth, non-reflective finish. 3. No. 4 Finish: Also known as brushed or satin finish, this surface texture is obtained by mechanically polishing the stainless steel sheet. It has a brushed appearance with fine parallel lines, providing a textured and decorative finish. 4. No. 8 Finish: This surface texture, also referred to as mirror or reflective finish, is achieved by polishing the stainless steel sheet to a high shine. It has a glossy, mirror-like appearance that reflects light and adds a luxurious touch to applications. 5. Embossed Finish: This surface texture involves impressing a pattern or design onto the stainless steel sheet. It can range from simple textures like diamond or linen patterns to more intricate designs, providing both visual interest and improved grip for certain applications. 6. Bead Blast Finish: This surface texture is created by blasting the stainless steel sheet with fine glass beads or other abrasives. It produces a uniform, matte finish with a slightly roughened texture, suitable for applications where a subdued appearance is desired. 7. Etched Finish: This surface texture involves chemically etching the stainless steel sheet to create patterns or designs. It can produce intricate and detailed textures, offering a unique and artistic finish. These are just a few examples of the different surface textures available for stainless steel sheets. Each texture has its own distinct characteristics, allowing for a range of design possibilities in various industries such as architecture, interior design, automotive, and more.

- Q: What are the standard sizes and thicknesses of stainless steel sheets?

- Stainless steel sheets are utilized in numerous industries and applications due to their wide range of standard sizes and thicknesses. Typically, the standard sizes vary from 4 feet by 8 feet to 5 feet by 10 feet, but customized sizes can also be obtained based on specific needs. In terms of thickness, stainless steel sheets are offered in various standard options. These include 20 gauge (0.036 inches), 18 gauge (0.048 inches), 16 gauge (0.060 inches), 14 gauge (0.075 inches), 12 gauge (0.105 inches), and 10 gauge (0.135 inches). It is important to note that these thicknesses indicate the nominal thickness, and the actual thickness may have slight variations. Additionally, it is worth noting that stainless steel sheets are also available in metric sizes. Common thicknesses in metric sizes range from 0.5 mm to 3 mm. This provides flexibility and compatibility with international standards and specifications. In summary, the standard sizes and thicknesses of stainless steel sheets are determined by industry standards and customer requirements. This ensures their widespread availability and versatility for various applications such as construction, automotive, aerospace, and kitchen equipment manufacturing, among others.

- Q: Can stainless steel sheets be used for outdoor signage or billboards?

- Certainly! Outdoor signage or billboards can indeed utilize stainless steel sheets. Stainless steel possesses exceptional durability, effectively combating corrosion, rust, and fading. Consequently, it proves ideal for outdoor applications. It exhibits remarkable resilience against inclement weather conditions, such as rain, snow, and harmful UV rays, without compromising its integrity. Moreover, stainless steel sheets provide a sleek and contemporary aesthetic, elevating the visual allure of outdoor signage or billboards. Furthermore, stainless steel can be easily manipulated and fashioned into various shapes and sizes, empowering designers with endless possibilities for customization and innovation. In conclusion, stainless steel sheets offer a dependable and enduring choice for outdoor signage or billboards.

- Q: Can stainless steel sheets be used for athletic equipment?

- Indeed, athletic equipment can make use of stainless steel sheets. Renowned for their durability, resistance to corrosion, and strength, stainless steel proves to be the perfect material for myriad athletic equipment purposes. Gym equipment, like weightlifting bars, dumbbells, and exercise benches, regularly employs stainless steel in its construction. Moreover, basketball hoops, soccer goalposts, and other outdoor sports equipment rely on stainless steel sheets for their ability to endure harsh weather conditions. Furthermore, stainless steel sheets offer versatility by allowing customization and fabrication into a range of shapes and sizes, catering to diverse athletic equipment requirements.

- Q: Is Baoding mirror stainless steel plate mirror on both sides?

- Both the 201 or 304 material, double sided 8K mirror stainless steel plate can do.

- Q: How do I prevent stress relaxation on stainless steel sheets?

- Stress relaxation is a phenomenon that occurs in stainless steel sheets when they are subjected to prolonged exposure to high temperatures or constant stress. To prevent stress relaxation on stainless steel sheets, you can take the following measures: 1. Proper selection of stainless steel grade: Different grades of stainless steel have varying resistance to stress relaxation. Choose a grade that offers high resistance to this phenomenon, such as austenitic stainless steels like Type 304 or Type 316. 2. Avoid excessive temperatures: Stainless steel sheets should be operated within their recommended temperature limits. Exposing them to temperatures beyond their specified range can accelerate stress relaxation. Ensure that the operating temperature remains within the permissible limits. 3. Control the stress levels: Minimize the stress levels applied to the stainless steel sheets during fabrication and installation. Avoid excessive bending, stretching, or deformation that could introduce stress into the material. Properly design and fabricate the components to reduce stress concentration points. 4. Post-weld heat treatment: If the stainless steel sheets are welded, consider performing a post-weld heat treatment. This process involves subjecting the welded area to controlled heating and cooling cycles to relieve residual stresses and minimize the potential for stress relaxation. 5. Reduce exposure to aggressive environments: Stainless steel sheets are corrosion-resistant, but exposure to aggressive chemicals or environments can accelerate stress relaxation. Avoid prolonged exposure to corrosive substances or environments that may compromise the material's integrity and cause stress relaxation. 6. Regular inspections and maintenance: Periodically inspect the stainless steel sheets for signs of stress relaxation, such as deformation, cracks, or changes in dimensions. Regular maintenance and timely repairs can help identify and address any issues before they worsen. 7. Consult with experts: If you are unsure about the specific requirements to prevent stress relaxation in your stainless steel sheets, consult with metallurgical experts or stainless steel manufacturers. They can provide guidance on the best practices and materials to ensure long-term performance and prevent stress relaxation. By implementing these preventive measures, you can significantly reduce the risk of stress relaxation in stainless steel sheets, ensuring their durability and maintaining their structural integrity over time.

- Q: What's the difference between stainless steel coil and stainless steel plate?

- The chemical resistance of the medium (acid, alkali, salt and other chemical etching) corrosion of steel called acid resistant steel. Because of the difference in the chemical composition of the two, and make their corrosion resistance is different, ordinary stainless steel is generally not resistant to chemical medium corrosion, and acid resistant steel are generally stainless steel.

- Q: What is the maximum width of stainless steel sheets available?

- The supplier and customer requirements can cause variations in the maximum width of stainless steel sheets. Typically, these sheets come in widths ranging from 36 inches (91.44 cm) to 72 inches (182.88 cm). However, certain specialty suppliers may have wider options, exceeding 96 inches (243.84 cm) or even more. It is crucial to consider that wider sheets might incur higher production expenses and longer delivery times. Therefore, customers should consult their supplier to ascertain the maximum width suitable for their particular demands.

Send your message to us

Stainless Steel Plate Sheet 304 2mm 3mm Custom Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords