Stainless Steel Plate 444 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

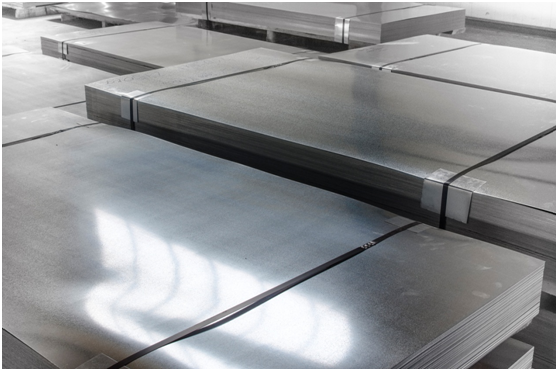

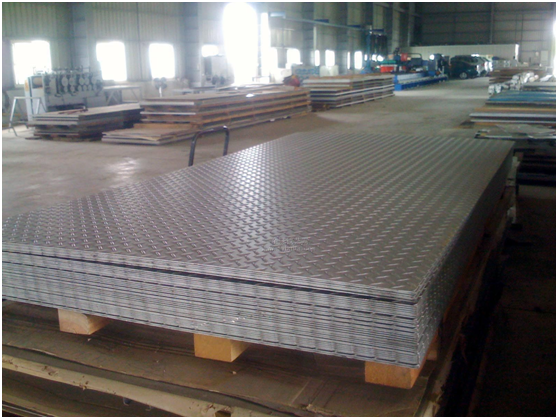

Stainless Steel Plate 444 with Surface Treatment

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

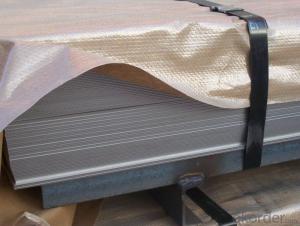

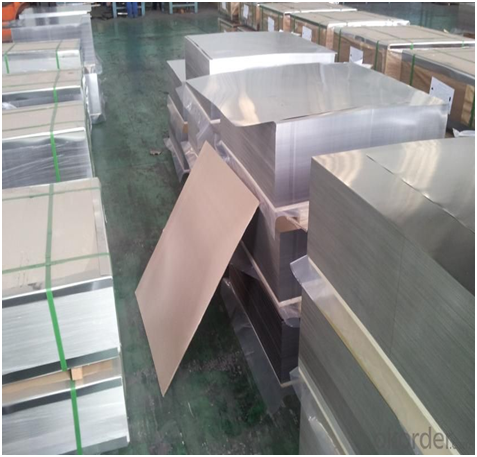

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for fermentation tanks?

- Yes, stainless steel sheets can be used for fermentation tanks. Stainless steel is a preferred material for fermentation tanks due to its durability, corrosion resistance, and ability to maintain the desired temperature. It is non-reactive, which means it does not interact with the fermenting substances, ensuring the purity and quality of the product. Stainless steel is also easy to clean and sanitize, which is crucial for maintaining hygienic conditions during the fermentation process. Additionally, stainless steel sheets can be fabricated into various shapes and sizes to meet specific fermentation tank requirements. Overall, stainless steel sheets are a reliable and popular choice for fermentation tanks in various industries, including brewing, winemaking, and food processing.

- Q: 304 why is stainless steel magnetic?

- Some people often think that the inspection of stainless steel with good or bad, using a magnet, magnet does not smoke, no magnetic, genuine; smoke, then there is magnetism, is considered a fake fake. In fact, this is an extremely one-sided and unrealistic method of discrimination.Generally speaking, stainless steel has magnetism and also has no magnetism. The austenite is nonmagnetic or weakly magnetic, such as 201, 202, 304, 316, etc. the martensite or ferrite is magnetic, such as 430, 420, 410, etc..

- Q: How do you measure the thickness of stainless steel sheets?

- There are multiple methods available for measuring the thickness of stainless steel sheets. One commonly used approach involves the utilization of a caliper, which is a precision measuring tool. By placing the jaws of the caliper on both sides of the sheet and tightening them until contact is made, the thickness can be directly measured. The reading on the caliper will provide an indication of the sheet's thickness. Alternatively, a more accurate method for measuring very thin sheets is through the use of a micrometer, which functions similarly to a caliper. By employing a spindle and anvil, the micrometer can provide precise measurements of thickness. This method is frequently employed in industries where accuracy is of utmost importance, such as manufacturing and engineering. In the absence of a caliper or micrometer, a simple ruler or tape measure can be utilized. Although this method may not provide the same level of accuracy as specialized tools, it can still offer a rough estimate of the thickness. By measuring the height of the sheet, assuming it is uniformly thick, one can infer the sheet's thickness. It is worth noting that the appropriate measurement tool depends on the thickness of the stainless steel sheet. Micrometers and calipers are best suited for measuring thinner sheets, while thicker sheets may require more specialized instruments like ultrasonic thickness gauges. In conclusion, the thickness of stainless steel sheets can be measured using various methods, including calipers, micrometers, rulers, or tape measures. The choice of tool depends on the desired level of accuracy and the thickness of the sheet being measured.

- Q: What are the different edge finishes available for stainless steel sheets?

- There are several different edge finishes available for stainless steel sheets, each with its own unique characteristics and applications. 1. Mill Edge: This is the original edge produced during the rolling process at the mill. It has a slightly rough appearance and may contain mill scale or imperfections. Mill edge is suitable for applications where aesthetics are not a major concern, such as industrial or structural use. 2. Sheared Edge: This edge is obtained by shearing or cutting the stainless steel sheet to size. It has a straight, clean-cut appearance and is commonly used in applications where a smooth edge is desired, such as architectural or decorative purposes. 3. Deburred Edge: After the shearing process, the edges of the stainless steel sheet can be deburred to remove any sharp or rough edges. This creates a smooth and safe edge, making it suitable for applications where safety is a concern, such as food processing or medical equipment. 4. Rolled Edge: This edge finish is achieved by rolling the stainless steel sheet, which creates a rounded or curved edge. Rolled edges are often used in applications where safety is important, as they eliminate sharp corners and edges, reducing the risk of injury. 5. Beveled Edge: A beveled edge is created by cutting or grinding an angle onto the edge of the stainless steel sheet. This edge finish is commonly used in architectural or decorative applications, as it offers a stylish and visually appealing appearance. 6. Polished Edge: This edge finish involves polishing the edge of the stainless steel sheet to a smooth and reflective surface. Polished edges are often used in high-end architectural or decorative applications, as they enhance the overall aesthetic appeal of the stainless steel sheet. It is important to choose the appropriate edge finish based on the specific requirements of your application, taking into consideration factors such as aesthetics, functionality, and safety.

- Q: What are stainless steel sheets?

- Stainless steel sheets are flat pieces of metal made from stainless steel, a type of alloy that contains chromium, nickel, and other elements. These sheets are highly versatile and widely used in various industries for their excellent corrosion resistance, durability, and aesthetic appeal. They are manufactured through a process called hot rolling or cold rolling, which involves passing the steel through a series of rollers to achieve the desired thickness and finish. Stainless steel sheets are commonly used for applications such as construction, automotive manufacturing, kitchenware, appliances, and architecture. They come in different grades, surface finishes, and sizes to cater to different requirements. Whether it's for decorative purposes or functional applications, stainless steel sheets offer a reliable and long-lasting solution.

- Q: Can stainless steel sheets be used for architectural façades?

- Yes, stainless steel sheets can be used for architectural façades. Stainless steel is a durable and versatile material that offers many advantages for façade applications. It is resistant to corrosion, weathering, and staining, making it an ideal choice for exterior use. Stainless steel sheets can be fabricated into various shapes and sizes, allowing for a wide range of design options. Additionally, stainless steel can be finished in different ways, such as brushed, polished, or colored, providing further aesthetic possibilities. Its strength and rigidity also make it suitable for large-scale installations. Overall, stainless steel sheets offer durability, aesthetic appeal, and design flexibility, making them a popular choice for architectural façades.

- Q: What is the maximum thickness available for stainless steel sheets?

- The specific grade of stainless steel and the manufacturing capabilities of the supplier can cause the maximum thickness of stainless steel sheets to differ. Nevertheless, stainless steel sheets are commonly available in thicknesses ranging from 0.5mm to 80mm. It should be emphasized that thicker sheets are typically utilized for specialized purposes that demand heightened strength and durability, like construction projects or heavy machinery. To ensure the desired thickness is obtainable, it is essential to carefully consider the intended use of the stainless steel sheets and seek advice from a reputable supplier.

- Q: Can stainless steel sheets be custom-cut?

- Stainless steel sheets have the capability to be tailored to specific sizes and dimensions. This adaptable material can be easily molded and formed to meet individual needs. The custom-cutting of stainless steel sheets is widely practiced across multiple industries, including construction, manufacturing, and fabrication. This procedure guarantees a precise fit for various purposes, such as architectural projects, machinery components, or kitchen equipment. Expert metal fabricators or specialized service providers commonly employ advanced techniques like laser cutting, waterjet cutting, or shearing to accurately customize stainless steel sheets according to desired specifications.

- Q: How can stainless steel sheets be cleaned and maintained?

- Stainless steel sheets are highly durable and resistant to corrosion, making them a popular choice for various applications. To maintain the appearance and functionality of stainless steel sheets, regular cleaning and proper maintenance are essential. Here are some steps to clean and maintain stainless steel sheets: 1. Start by removing any loose dirt or debris from the surface using a soft cloth or a brush. This step helps prevent scratching during the cleaning process. 2. Prepare a cleaning solution by mixing warm water with a mild detergent or dish soap. Avoid using abrasive cleaners or products containing chlorine, bleach, or ammonia, as they can damage the stainless steel surface. 3. Dip a soft cloth or sponge in the cleaning solution and gently scrub the stainless steel sheet in the direction of the grain. Avoid using excessive pressure to prevent scratching. 4. Rinse the sheet thoroughly with clean water to remove any residue from the cleaning solution. Ensure all soap or detergent is completely washed away. 5. Dry the stainless steel sheet using a soft, lint-free cloth. It is important to dry it thoroughly to prevent water spots or streaks from forming. 6. For stubborn stains or fingerprints, use a stainless steel cleaner or specialized stainless steel wipes. Follow the manufacturer's instructions on the product for best results. These cleaners can help restore the shine and remove any tough stains or marks. 7. To prevent scratches, avoid using abrasive materials such as steel wool or rough brushes when cleaning stainless steel sheets. Instead, use soft cloths or non-abrasive sponges. 8. Regularly inspect the stainless steel sheets for any signs of corrosion or damage. If any rust spots or pitting are noticed, use a stainless steel cleaner or passivation solution to restore the surface. Consult with a professional if the damage is extensive. 9. To maintain the appearance of the stainless steel sheet, it is recommended to wipe the surface regularly with a soft cloth or microfiber towel to remove dust, fingerprints, or other marks. By following these cleaning and maintenance steps, stainless steel sheets can retain their original shine, resist corrosion, and remain in excellent condition for an extended period.

- Q: Are stainless steel sheets easy to clean?

- Yes, stainless steel sheets are easy to clean. They have a smooth surface that is resistant to stains and can be easily wiped clean with soap and water. Additionally, they are also resistant to rust and corrosion, making them low-maintenance and suitable for various applications.

Send your message to us

Stainless Steel Plate 444 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords