Seamless Steel Pipe High Quality/Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 3000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DETAILS

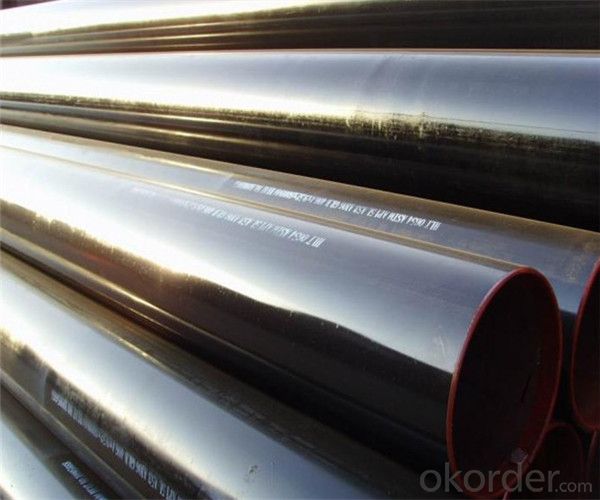

1.Structure of Seamless Steel Pipe Description:

A large amount of Seamless Steel Pipes is offered to the clients at cost effective rates. These pipes are extremely durable, resistant to corrosion and have high tensile strength. Our pipes are used in nuclear plants, power plants, refineries and construction industry across the country. Furthermore, we are capable of providing these seamless pipes to the clients in bulk quantity.

2.Main Features of the Steel Pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

•Reasonable price

3.Packaging & Delivery:

| Packaging Details: | Seaworthy packages, bundles wrapped with strong steel strip |

| Delivery Detail: | 15-30 days after received 30% TT |

4.Seamless Steel Pipe Specification:

| Standard: | GB, DIN, ASTM,ASME, ASTM A106-2006, ASTM A53-2007 |

| Grade: | 10#,20#, 45#, 16Mn |

Thickness: | 8 - 33 mm |

| Section Shape: | Round |

| Outer Diameter: | 133 - 219 mm |

| Place of Origin: | Shandong, China (Mainland) |

| Secondary Or Not: | Non-secondary |

| Application: | Hydraulic Pipe |

| Technique: | Cold Drawn |

| Certification: | API |

| Surface Treatment: | factory state or painted black |

| Special Pipe: | API Pipe |

| Alloy Or Not: | Non-alloy |

| Length: | 5-12M |

| Outer Diameter: | 21.3-610mm |

5.FAQ of Seamless steel pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust.

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: How are steel pipes used in tunnel construction?

- Steel pipes are commonly used in tunnel construction for various purposes. They are used to provide structural support by acting as reinforcements or casings for the tunnel walls. Steel pipes also serve as conduits for utilities such as water, gas, and electricity within the tunnel. Additionally, they can be used for ventilation and drainage systems, ensuring a safe and functional environment inside the tunnel. Overall, steel pipes play a crucial role in the construction and functionality of tunnels.

- Q: Can steel pipes be used for flagpoles?

- Yes, steel pipes can be used for flagpoles.

- Q: Can steel pipes be used for water supply systems?

- Yes, steel pipes can be used for water supply systems. Steel pipes are commonly used in water supply systems due to their durability, strength, and resistance to corrosion. However, it is important to ensure that the steel pipes are properly coated or lined to prevent any potential leaching of metals into the water supply. Additionally, regular maintenance and inspection is necessary to prevent any damage or deterioration that could affect the overall integrity of the water supply system.

- Q: How are steel pipes used in industrial manufacturing processes?

- Steel pipes are commonly used in industrial manufacturing processes for various purposes, such as transporting fluids, gases, and solids, as well as providing structural support. They are used to create pipelines for water, oil, and gas transportation, as well as for conveying materials like ores and grains. Additionally, steel pipes are utilized in machinery, equipment, and infrastructure construction due to their strength, durability, and resistance to high pressure and extreme temperatures.

- Q: How are steel pipes insulated for thermal purposes?

- Steel pipes are commonly insulated for thermal purposes using a variety of methods. One of the most common methods is to wrap the pipes with insulation material such as fiberglass, mineral wool, or foam. This insulation material acts as a barrier between the pipe and the surrounding environment, preventing heat transfer or loss. To properly insulate steel pipes, the insulation material is typically wrapped tightly around the pipe, ensuring that there are no gaps or openings for heat to escape. The insulation is then secured in place using adhesive tapes or metal bands. In addition to external insulation, pipes can also be internally insulated. This involves placing insulation material inside the pipe, creating a layer of protection against heat loss or gain. Internal insulation is commonly used in applications where the pipe carries hot fluids or gases. Furthermore, some steel pipes are designed with a built-in insulation layer. These pipes, known as pre-insulated pipes, have insulation material already integrated into the pipe structure. The insulation layer is typically made of foam or mineral wool and is covered with a protective outer layer, providing effective thermal insulation. Insulating steel pipes for thermal purposes is crucial in various industries, such as oil and gas, HVAC, and plumbing. Proper insulation helps to maintain the desired temperature of the fluid or gas flowing through the pipes, preventing energy loss and improving overall efficiency.

- Q: Are steel pipes suitable for underground gas distribution?

- Steel pipes are indeed appropriate for the distribution of gas underground. Due to their remarkable strength, durability, and resistance to corrosion, steel pipes are extensively employed in gas distribution systems. The ability of steel pipes to endure the pressure and stress in underground environments renders them a dependable choice for gas transportation. Moreover, steel pipes possess the added benefit of being capable of withstanding high temperatures and resisting fire, making them a secure alternative for underground gas distribution. Nonetheless, it is crucial to ensure that the steel pipes employed are adequately coated and shielded against corrosion to guarantee their longevity and avert any possible leaks or harm.

- Q: How are steel pipes transported?

- Steel pipes can be transported through different means depending on their size, weight, and the distance they need to cover. The primary modes of transportation for steel pipes are trucks, trains, and ships. For shorter distances, trucks are often used to transport steel pipes. The pipes are loaded onto flatbed or specialized trailers designed to securely hold and transport them. Trucks are convenient for transporting steel pipes to nearby locations or construction sites, as they can easily navigate local roads and highways. For longer distances, trains are the preferred mode of transportation. Steel pipes are loaded onto flatcars, which are specifically designed to carry heavy loads. Trains offer a cost-effective and efficient means of transporting large quantities of steel pipes over long distances. They can accommodate pipes of various lengths and diameters, making them a versatile option. When it comes to international shipments or transportation over bodies of water, ships are commonly used. Steel pipes can be loaded into shipping containers or onto the deck of cargo ships. Shipping containers provide protection from weather conditions and ensure the pipes remain secure during transit. Specialized ships equipped with cranes can handle large and heavy pipes, making the transportation of oversized steel pipes possible. In certain cases, pipelines can be constructed to transport steel pipes directly from the manufacturing facility to the desired location. This method is commonly used for oil, gas, or water pipelines. By laying the pipes underground, the need for separate transportation is eliminated. Overall, the transportation of steel pipes involves a range of methods, including trucks, trains, ships, and pipelines. The choice of method depends on factors such as distance, quantity, and project requirements. Each method offers its own advantages and is selected based on considerations such as cost, efficiency, and logistics.

- Q: How do you measure the thickness of a steel pipe?

- Different methods can be used to measure the thickness of a steel pipe, depending on the required precision and available tools. Here, we present three commonly used approaches: 1. Calipers or Vernier Calipers: These are widely used and straightforward tools for measuring thickness. Place the jaws of the calipers on both sides of the pipe, ensuring they are perpendicular to the surface. Gently close the jaws until they touch the pipe, and then read the measurement on the caliper scale. 2. Ultrasonic Thickness Gauge: This method provides more accurate results and is commonly employed in industrial settings. An ultrasonic thickness gauge emits high-frequency sound waves that penetrate the steel pipe. By measuring the time it takes for the sound waves to bounce back, the gauge calculates the pipe's thickness. Before taking the measurement, ensure that the pipe surface is clean and smooth. 3. Magnetic Thickness Gauge: This method is specifically designed for measuring the thickness of ferrous materials like steel. The gauge incorporates a small magnet that adheres to the pipe surface. By applying a magnetic field, the gauge determines the distance between the magnet and the base plate. This distance corresponds to the thickness of the steel pipe. It is important to consider that each method has its own limitations in terms of accuracy. The choice of measurement technique should be based on the desired precision, availability of tools, and the specific requirements of the application.

- Q: What is the cost of steel pipes?

- The cost of steel pipes can vary depending on factors such as the size, grade, and quantity needed, as well as market conditions and supplier. It is recommended to contact suppliers or check online platforms to get specific pricing information.

- Q: Can steel pipes be used for oil refineries?

- Yes, steel pipes can be used for oil refineries. Steel pipes are commonly used in oil refineries due to their high strength, durability, and resistance to corrosion. They can handle the high pressure and temperature requirements of the oil refining process, making them suitable for transporting and distributing various petroleum products within the refinery.

Send your message to us

Seamless Steel Pipe High Quality/Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 3000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords