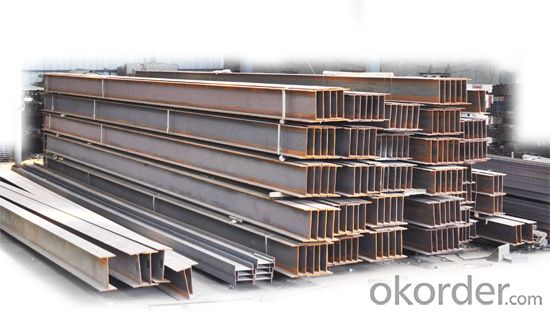

Steels China Manufacture Building Material Construction on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Packaging & Delivery

Packaging Detail: | in bundles or as customer's requirement |

Delivery Detail: | Within 30days after receiving your deposit or copy of L/C |

2.Specifications

HRB400,HRB500 Steel Rebars

1.China direct supplier

2.Best service

3.Competitive price

4.Quantity assured

3.Product Description

Name | High Tensile Export Reinforcing Steel Bar ,Deformed Steel Bar ,HRB400B,HRB,46B,HRB500 Building Construction Material |

Standard | ASTM A615 /BS BS 4449 /GB HRB/ JIS G3112 |

Grade | A615 Gr40/60/75 BS 4449 Gr460,B500 GB HRB335,HRB400 ,HRB500

JIS G3112 SD390

|

Diameter | 6mm-40mm |

Length | 6-12m |

Technique | Low temperature hot-rolling reinforcing deformed steel rebar |

Tolerance | As the standard or as your requirement |

Application | Building, construction, road, bridge,etc |

Certificated | BV |

MOQ | 500tons per size steel rebar |

Packing details | Steel rebar packed in bundle or as your requirement |

Delivery | Within 30 days after deposit |

Payment | T/T or L/C |

4.Chemical Composition

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%)

| ||||||

≥400 | ≥470 | ≥14 | ||||||

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB500 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

≥500 | ≥630 | ≥12 | ||||||

5. Theorectical weight

Diameter (MM) | Cross Sectional Area (MM2) | Theorectical Weight (KG/M) | Weight of 12M Bar (KG) | A Ton Contains 12M Bars (PCS) |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

- Q: Are steel pipes resistant to corrosion?

- Yes, steel pipes are generally resistant to corrosion due to the protective layer of oxide that forms on their surface, but their resistance can vary depending on the specific grade of steel and the environment they are exposed to.

- Q: What is the diameter of the steel tube DN20?

- 1, nominal diameter is nominal diameter, or nominal diameter, or nominal size.2, nominal diameter is a variety of pipe and pipe accessories generic caliber. The same nominal diameter of the tube and pipe accessories can connect with each other, with interchangeability. It is not a real sense of the pipe diameter or diameter, although its value is closer with the pipe diameter or equivalent, is a convenient integer for reference only, are not strict with processing size. Nominal diameter is not the outer diameter, nor the inner diameter, but a nominal size similar to the diameter of the ordinary steel pipe. In order to connect the pipe and pipe fittings in a uniform dimension, each nominal diameter corresponds to an outer diameter, and the inner diameter value varies with the thickness.

- Q: A333gr6 steel pipe and domestic material of the same?

- A333Gr.6 steel is no nickel steel is a kind of fine grain aluminum low temperature toughness of steel, therefore, also called Al killed steel. A333Gr.6 belongs to the United States ANSI and ASTM-SA333 cryogenic steel standards and is used at the lowest impact temperature of -46 degrees celsius. Its temperature, range of use and fracture toughness value are similar to those of domestic 16Mn steel (the minimum usage temperature of 16Mn steel is -40 degrees Celsius).

- Q: Can steel pipes be used for underground sprinkler systems?

- Yes, steel pipes can be used for underground sprinkler systems. Steel pipes are known for their durability and strength, making them a suitable choice for underground applications. They are resistant to corrosion and can withstand high pressure and temperature, making them suitable for delivering water to sprinkler heads. However, it is important to note that steel pipes may require additional coatings or protective measures to prevent rusting and corrosion over time. Additionally, steel pipes may be more expensive than other materials such as PVC or polyethylene, so the cost factor should be considered as well. Overall, steel pipes can be a viable option for underground sprinkler systems, particularly in areas with harsher environmental conditions.

- Q: Can steel pipes be used for culvert applications?

- Indeed, culvert applications can utilize steel pipes. The utilization of steel pipes for culverts is widespread owing to their exceptional endurance, robustness, and immunity to corrosion. They possess the capability to endure substantial burdens, accommodate extensive traffic flow, and manage large water surges. Furthermore, steel pipes can be effortlessly fabricated in diverse dimensions and configurations to cater to specific culvert prerequisites. Their prolonged lifespan and minimal upkeep demands render them a cost-efficient alternative for culvert applications.

- Q: Why seamless steel pipe called seamless steel pipe?

- Seamless steel pipe is a hollow section, without the joint round, square, rectangular steel. Seamless steel tubes are made of ingots or billets made by piercing and are then made by hot rolling, cold rolling or cold casting. Seamless steel pipe with a hollow section, as pipe conveying fluid, compared withsteel and roundsteelinsolid, flexural torsional strength in the same time, the weight is light, is a kind of economic section steel, widely used in the manufacture of structural parts and mechanical parts, such as the oil pipe, automobile transmission shaft, bike frame and construction using steel scaffolding.

- Q: What are the main components of a steel pipe?

- The main components of a steel pipe are the pipe body, which is made of steel and provides structural strength and durability, and the pipe ends, which can be either threaded or plain and are used for connecting and joining the pipe to other components or systems. Additionally, steel pipes may also have protective coatings or linings to enhance corrosion resistance and prolong their lifespan.

- Q: Can steel pipes be used for fire protection systems?

- Yes, steel pipes can be used for fire protection systems. Steel pipes are commonly used in fire sprinkler systems due to their durability, strength, and resistance to high temperatures. They are capable of withstanding the heat and pressure generated during a fire, making them suitable for fire protection applications. Additionally, steel pipes can be easily connected and installed, ensuring efficient and reliable fire suppression in buildings.

- Q: What is the difference between hot-finished and cold-finished steel pipes?

- Distinguishing hot-finished and cold-finished steel pipes can be done by examining their manufacturing processes, which lead to different characteristics and applications. To create hot-finished steel pipes, a solid steel billet is heated to a high temperature and then pierced to form a hollow tube. This process, known as hot rolling, ensures that the steel is easily shaped and malleable. As a result, hot-finished steel pipes have rough surfaces and rounded edges. They are generally larger in diameter and have thicker walls. These pipes are commonly utilized in industries that demand high strength and pressure resistance, like the oil and gas sector, structural projects, and heavy machinery manufacturing. On the other hand, cold-finished steel pipes are produced using a process called cold drawing. This involves pulling the hot-finished steel pipe through a die at room temperature to reduce its diameter and achieve the desired shape. The cold drawing process yields a more precise and smoother finish for the steel pipes. Cold-finished steel pipes possess smoother surfaces and sharper edges compared to their hot-finished counterparts. They are typically smaller in diameter and have thinner walls. Cold-finished steel pipes are commonly applied in industries that require accurate dimensions, such as automotive part manufacturing, construction component fabrication, and machinery production. In conclusion, the primary disparity between hot-finished and cold-finished steel pipes stems from their manufacturing processes, resulting in variations in surface finish, dimensions, and applications. Hot-finished pipes are suitable for applications that demand high strength and pressure resistance, while cold-finished pipes are ideal for applications that require precise dimensions and smooth surfaces.

- Q: How are steel pipes used in HVAC systems?

- Steel pipes are used in HVAC systems for various purposes such as transporting hot or cold water, steam, or refrigerant throughout the system. They are commonly used for supply and return lines, as well as for connecting various HVAC components like chillers, boilers, air handlers, and heat exchangers. Steel pipes are preferred in HVAC systems due to their durability, strength, and resistance to corrosion and high pressure.

Send your message to us

Steels China Manufacture Building Material Construction on Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords