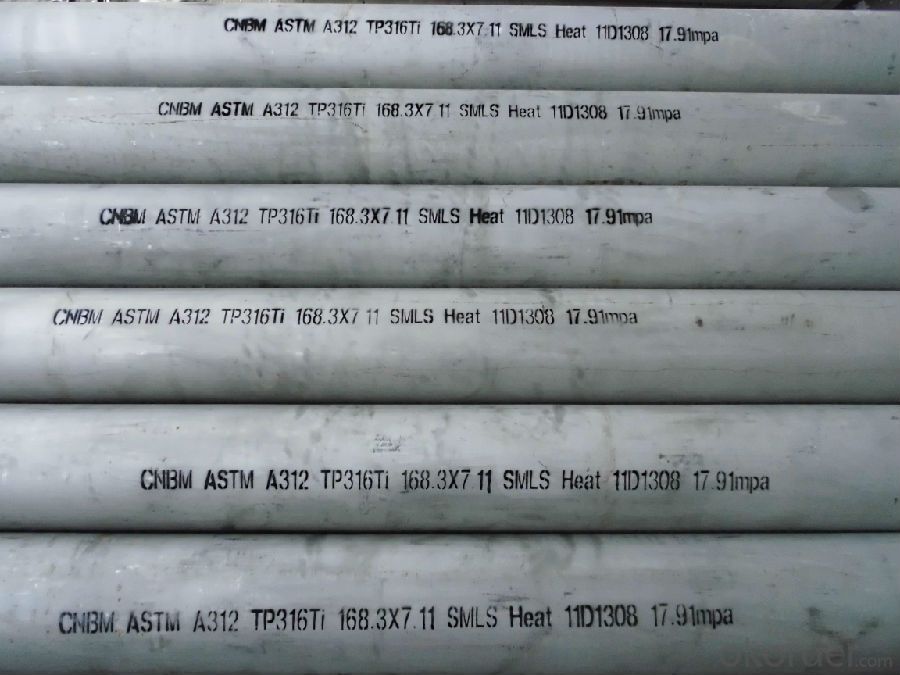

Stainless steel pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

316Ti stainless steel plate is the addition of Ti in SUS316 steel can improve the resistance to intergranular corrosion resistance.

The chemical composition of 316Ti stainless steel:

C (%): less than 0.08

Si (%): less than 1

Mn (%): less than 2

P (%) is less than or equal to: 0.045

S (%) is less than or equal to 0.03

Cr (%): 16 ~ 18

Ni (%): 10 ~ 14

Mo (%): 2 ~ 3

other (%):

5 (C+N) = Ti = 0.70, N = 0.10

The mechanical properties of 316Ti stainless steel:

YS (Mpa) = 205 TS (Mpa) = 520 EL (%) is more than or equal to 40 Hv 200 degrees

- Q: Can steel pipes be used for water wells?

- Yes, steel pipes can be used for water wells. Steel pipes are commonly used in water well drilling due to their durability, strength, and resistance to corrosion.

- Q: How are steel pipes recycled at the end of their life cycle?

- Steel pipes are typically recycled at the end of their life cycle by first being collected and sorted at recycling facilities. They are then cleaned and processed to remove any contaminants. The pipes are further broken down into smaller pieces and melted in a furnace. Once the molten steel is formed, it can be used to create new steel products, such as pipes or other construction materials. This recycling process helps reduce the demand for new steel production and conserves valuable resources.

- Q: What is the minimum wall thickness for steel pipes?

- The minimum wall thickness of steel pipes varies depending on different factors, including the pipe's intended use and the specific industry standards and regulations. Determining the minimum wall thickness generally involves considering factors like the pipe's diameter, material strength, and the pressure or load it will experience during operation. In the oil and gas industry, for instance, the minimum wall thickness for steel pipes is typically specified by industry standards such as API 5L or ASME B31.3. These standards take into account elements such as the pipe's diameter, the material's yield strength, and the maximum pressure it will encounter. In other applications, such as structural or mechanical engineering, the minimum wall thickness for steel pipes is determined by factors like the pipe's intended load-bearing capacity, the desired safety factor, and any relevant building codes or regulations. To establish the specific minimum wall thickness requirements for steel pipes in a particular application, it is essential to consult the appropriate industry standards, codes, or regulations.

- Q: What are the common methods for repairing steel pipes?

- Some common methods for repairing steel pipes include welding, pipe wrapping, pipe relining, and pipe bursting.

- Q: How do you clean steel pipes?

- To effectively clean steel pipes, there are several steps that can be followed: 1. Collect the necessary supplies: You will require a pipe cleaning solution, either a scrub brush or wire brush, and safety gear like gloves and goggles. 2. Prepare the cleaning solution: Dilute the pipe cleaning solution according to the instructions provided on the packaging. Ensure that you select a solution suitable for steel pipes. 3. Prioritize safety: Put on your safety gear to safeguard yourself from any potential hazards. 4. Eliminate any debris: Before applying the cleaning solution, eliminate any loose debris or dirt from the surface of the steel pipes. You can utilize a brush or cloth to wipe away any visible particles. 5. Apply the cleaning solution: Immerse the brush into the prepared cleaning solution and administer it to the steel pipes. Ensure that you cover the entire surface, particularly focusing on areas with stubborn dirt or grime. 6. Scrub the pipes: Thoroughly scrub the steel pipes using the brush, applying pressure as needed to eliminate any buildup or stains. Pay extra attention to joints or hard-to-reach areas. 7. Rinse with water: Once you have completed the scrubbing, rinse the pipes with clean water to eliminate the cleaning solution and any remaining dirt. You can pour water over the pipes or employ a hose if available. 8. Dry the pipes: After rinsing, use a cloth or towel to completely dry the steel pipes. This will aid in preventing water stains or corrosion. 9. Inspect for cleanliness: Take a moment to inspect the pipes and ensure that they are clean. If there are still areas with stubborn dirt or stains, you may need to repeat the cleaning process or consider using a different cleaning solution. Always remember to adhere to the manufacturer's instructions when using cleaning solutions and to take appropriate safety measures.

- Q: What are the different types of steel pipe supports for high-temperature applications?

- Some different types of steel pipe supports for high-temperature applications include hangers, clamps, brackets, and anchors. These supports are designed to withstand the elevated temperatures and provide stability and proper alignment to the piping system.

- Q: How are steel pipes used in the manufacturing of machinery and equipment?

- The manufacturing of machinery and equipment heavily relies on the widespread utilization of steel pipes, thanks to their numerous advantageous properties. These pipes serve as a primary means of conveying different materials, fluids, and gases within the machinery, effectively ensuring safe and efficient transportation. One crucial application of steel pipes in machinery manufacturing lies in the realm of hydraulic and pneumatic systems. Hydraulic systems depend on steel pipes to transmit power and regulate fluid flow, while pneumatic systems utilize these pipes to transport compressed air, powering various components. The strength and durability inherent in steel pipes guarantee their ability to withstand the immense pressure and forces exerted by these systems, making them a dependable choice for such purposes. Moreover, steel pipes find extensive use in the construction of machinery frames and structures. Their exceptional tensile strength and resistance to corrosion make them an ideal option for providing structural support and stability to heavy machinery. These pipes can be effortlessly welded, bent, and fabricated into diverse shapes, allowing for flexibility in design and enabling the creation of intricate machinery structures. Furthermore, steel pipes play an indispensable role in the transportation of raw materials and finished products throughout the manufacturing process. They frequently serve as conduits for the movement of liquids, gases, and granular materials, ensuring the smooth operation of machinery and equipment. Steel pipes are particularly well-suited for handling abrasive and corrosive materials, as their robust construction guarantees minimal wear and tear over time. In conclusion, the extensive utilization of steel pipes in the manufacturing of machinery and equipment stems from their strength, durability, and versatility. Whether it be for hydraulic systems, structural support, or material transportation, steel pipes form an integral component that significantly contributes to the efficiency and dependability of machinery across various industries.

- Q: How are steel pipes used in the construction of airports?

- Steel pipes are commonly used in the construction of airports for various purposes such as the installation of water and sewage systems, electrical conduits, and heating and cooling systems. They are also used as structural elements for supporting canopies, walkways, and other infrastructure, providing durability and stability to the airport's overall construction.

- Q: How are steel pipes repaired if they develop leaks?

- Steel pipes can be repaired if they develop leaks through various methods such as welding, clamping, or using epoxy compounds. The specific repair technique depends on the size and location of the leak as well as the type of pipe, and it is typically carried out by trained professionals with the necessary equipment and expertise.

- Q: Are steel pipes suitable for use in mining applications?

- Yes, steel pipes are suitable for use in mining applications. They are highly durable, resistant to corrosion, and can withstand high pressure and extreme temperatures often encountered in mining operations. Additionally, steel pipes have excellent structural integrity and can be easily welded, making them ideal for various mining activities such as transporting fluids, ventilation systems, and underground infrastructure.

Send your message to us

Stainless steel pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords