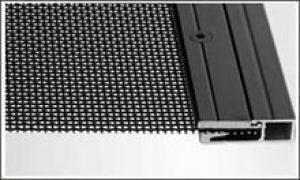

Stainless Steel Mesh Panel Hot Sale and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material:

201,202,302,304,304L,316,316L

Guage:

1.wire diameter:0.1-3.0mm

2.Mesh: 1-650mesh.

3.Width:0.5-5m

3.Length:30m

Weave way

Dutch weave

Plain weave

Twill weave

Stainless steel wire mesh kind:

1, stainless steel plain weave mesh. 2, stainless steel twill mesh. 3, stainless steel mesh bamboo pattern. 4, five mechanized stainless steel mesh. 5, stainless steel perforated metal mesh. 6, stainless steel crimped wire mesh. 7, stainless steel chain link fence. 8, stainless steel mesh. 9, stainless steel welded wire mesh. 10, stainless steel hexagonal. 11, stainless steel I-Net. 12, stainless steel wire meshes. 13, stainless steel mine screen. 14 mesh stainless steel shells.

- Q: What is the minimum temperature that steel pipes can handle?

- The minimum temperature at which steel pipes can withstand depends on the particular grade and composition of the steel. In general, steel pipes can endure extremely low temperatures without encountering significant issues. In fact, numerous steel varieties are specifically engineered to endure freezing temperatures, making them suitable for a range of uses in industries like oil and gas, construction, and cryogenics. However, it is crucial to acknowledge that steel may become more brittle at exceedingly low temperatures, which can impact its mechanical properties. Therefore, it is vital to meticulously choose the appropriate steel grade and consider any specific requirements or limitations for the desired application when determining the minimum temperature that steel pipes can handle.

- Q: Can steel pipes be used for underground sewerage systems?

- Yes, steel pipes can be used for underground sewerage systems. Steel pipes are commonly used in underground sewerage systems due to their durability, strength, and resistance to corrosion. They can withstand the weight of the soil and provide a long-lasting solution for transporting wastewater underground. Additionally, steel pipes are often preferred for larger diameter sewerage systems where high strength and structural integrity are crucial.

- Q: Can steel pipes be used for electrical conduits?

- No, steel pipes are not typically used for electrical conduits as they are conductive and can pose a safety risk. Electrical conduits are usually made of non-conductive materials such as PVC or metal with insulating coatings.

- Q: How do steel pipes handle soil movement?

- Steel pipes are able to handle soil movement quite well due to their inherent strength and durability. The rigid nature of steel pipes allows them to withstand ground shifting, settling, and other soil movements without significant deformation or damage. Additionally, steel pipes can be reinforced with additional supports and anchoring systems to further enhance their ability to handle soil movement.

- Q: How are steel pipes used in the wastewater treatment industry?

- Steel pipes are commonly used in the wastewater treatment industry for various applications such as transporting wastewater, distributing chemicals, and constructing infrastructure such as treatment plants and pumping stations. The durability, strength, and corrosion resistance of steel pipes make them ideal for handling the harsh and corrosive nature of wastewater, ensuring efficient and reliable operations in the industry.

- Q: How are steel pipes used in the chemical industry?

- Steel pipes are extensively used in the chemical industry for various applications, including transportation of chemicals, gases, and liquids. They are highly durable, corrosion-resistant, and can withstand high pressure and temperature conditions. Steel pipes are used in chemical plants for the transfer of raw materials, intermediate products, and final products within the production process. They are also employed for the distribution of utilities such as water, steam, and compressed air. Additionally, steel pipes are utilized for the construction of storage tanks, reactors, and other equipment in the chemical industry due to their strength and reliability.

- Q: What are the factors to consider when selecting the right steel pipe for a specific application?

- There are several factors to consider when choosing the appropriate steel pipe for a particular application. These factors encompass: 1. Compatibility with materials: Ensuring that the steel pipe is compatible with the substance it will transport or contain is crucial. Different materials may necessitate specific types of steel pipes to prevent corrosion or contamination. 2. Pressure and temperature requirements: The pressure and temperature conditions that the steel pipe will face should be taken into account. This will determine the necessary thickness and strength of the pipe to ensure it can withstand the intended operating conditions. 3. Size and dimensions: Selecting the size and dimensions of the steel pipe should be based on the flow rate, volume, and available installation space. It is vital to choose a pipe with the appropriate diameter and wall thickness to prevent flow restrictions or leaks. 4. Environmental conditions: The environment in which the steel pipe will be installed must be considered. Factors such as exposure to moisture, chemicals, or extreme temperatures may necessitate the use of specific coatings or materials to enhance the longevity and durability of the pipe. 5. Cost considerations: The cost of the steel pipe and its installation should be taken into account. Striking a balance between desired quality and available budget is essential to ensure the most cost-effective solution. 6. Regulatory compliance: Depending on the application, there may be specific industry regulations or standards that must be adhered to. Choosing a steel pipe that meets these requirements is important to ensure compliance and avoid any legal or safety issues. 7. Maintenance and lifespan: The maintenance requirements and expected lifespan of the steel pipe should also be considered. Some applications may require regular inspections or replacements, while others may require a more durable and long-lasting pipe. By carefully considering these factors, it is possible to select the appropriate steel pipe for a specific application that meets the desired performance, durability, and safety requirements.

- Q: What is the maximum operating temperature for steel pipes?

- The specific grade of steel used typically determines the maximum operating temperature for steel pipes. Carbon steel pipes, for instance, can generally endure temperatures ranging from 800-1000 degrees Fahrenheit (427-538 degrees Celsius). On the other hand, stainless steel or high-temperature alloys can withstand even higher temperatures, exceeding 1200-1500 degrees Fahrenheit (649-816 degrees Celsius). To determine the precise maximum operating temperature for a particular type of steel pipe, it is crucial to refer to the manufacturer's specifications or industry standards. This is because varying grades and compositions may have distinct temperature limits.

- Q: What are the different methods of insulating steel pipes?

- There are several different methods of insulating steel pipes, depending on the specific needs and requirements of the application. Some of the common methods include: 1. Insulation wraps: This method involves wrapping the steel pipes with insulating materials such as fiberglass, mineral wool, or foam insulation. The insulation is then secured with adhesive or tape to ensure a tight and secure fit. Insulation wraps are cost-effective and relatively easy to install, making them a popular choice for many applications. 2. Insulation coatings: This method involves applying a layer of insulating material directly onto the surface of the steel pipe. The coating can be made from materials such as epoxy, polyurethane, or polyethylene. Insulation coatings are ideal for situations where the pipes are exposed to harsh environments, as they provide a protective barrier against corrosion and temperature fluctuations. 3. Insulation jackets: This method involves using pre-fabricated insulation jackets that are designed to fit over the steel pipes. These jackets are typically made from a combination of insulation materials and a weatherproof outer layer. Insulation jackets are commonly used for outdoor or exposed pipelines, as they provide excellent insulation and protection against external elements. 4. Insulation foam: This method involves injecting foam insulation into the cavity between the steel pipe and an outer casing. The foam expands and hardens, creating a sealed and insulated layer around the pipe. Foam insulation is highly effective in preventing heat loss or gain, and it also provides excellent soundproofing properties. 5. Insulation tapes: This method involves using specialized insulation tapes that are wrapped around the steel pipes. These tapes are typically made from materials such as PVC or rubber, which have good insulating properties. Insulation tapes are often used for smaller pipes or joints, as they provide a flexible and easy-to-apply solution. It is important to consider factors such as the operating temperature, environmental conditions, and specific requirements of the application when choosing the appropriate method of insulating steel pipes. Consulting with a professional or insulation specialist can help in determining the most suitable insulation method for your specific needs.

- Q: Are steel pipes resistant to impact or external forces?

- Yes, steel pipes are generally resistant to impact or external forces due to their inherent strength and durability. They can withstand high pressure, heavy loads, and harsh environmental conditions, making them suitable for various applications, including construction, transportation, and industrial purposes.

Send your message to us

Stainless Steel Mesh Panel Hot Sale and High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords