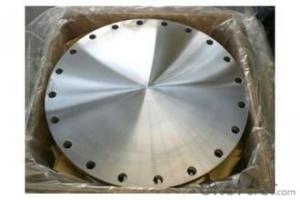

STAINLESS STEEL FORGED FLANGE 304/316 ASME B16.5 WELDING NECK

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Package Of Stainless Steel Flange:

PACKED IN PLYWOOD CASES OR PALLETS

Painting Of Stainless Steel Flange:

ANTI-RUST OIL

Marking Of Stainless Steel Flange:

REFER TO MARKING DOCUMENT or AS PER CUSTOMER REQUEST

Shipping Marks Of Stainless Steel Flange:

EACH WOODEN BOX TWO PLASTIC SHIPPING MARKS

Specification Of Stainless Steel Flange:

Carbon Steel Flange Slip On Flange, Plate Flange, Blind Flange, Welding Neck Flange, Socket Welded Flange, Thread Flange, Lap Joint Flange, Long Welding Neck Flange

Size : 1/2"-48"

Wall Thickness.: SCH10-SCH160, SGP , XS, XXS, DIN ,STD

| Name | Stainless Steel Flange |

| Size | 1/2" - 48" |

| Face | RF, FF, RTJ |

| Wall thickness | Sch5-Sch160 XXS,STD,XS, SGP |

| Standard | ASME B16.5, B16.47, BS4504, JIS B2220, API 6A, 11Detc. |

| We can also produce according to drawing and standards provided by customers. | |

| Material | 304, 304L, 316, 316L, 304/304L, 316/316L, EN1.4301, EN1.4404 etc. |

| Packaging | Wooden Cases, wooden pallet , or carton box , or nylog bag and then in wooden cases |

| Surface Treatment | Anti-rust Oil |

| Delivery Time | 20-30 days, after received advance payment. |

| Quality | 100% Heat Treatment, No Welding repair |

| Others | 1.Special design available according to your drawing. |

| 2.anti-corrosion and high-temperature resistant with black painting | |

| 3. All the production process are made under the ISO9001:2000 strictly. | |

| 4. A conformity rate of ex-factory inspection of products. | |

| 5. we have export right , offering FOB , CNF CIF price |

STANDARD & MATERIAL GRADE

STAMDARD Of Stainless Steel Flange

| Standard | Pressure | Size | |

| European Standard | EN 1092-1 | Class PN6 ~ PN100 | DN10 ~ DN4000 |

| American Standard | ASME B16.5 | Class 150 ~ 2500 | 1/2" ~ 24" |

| ASME B16.47A | Class 150 ~ 900 | 26" ~ 60" | |

| ASME B16.47B | Class 75 ~ 900 | 26" ~ 60" | |

| German Standard | DIN 2527,2566,2573, 2576, 2627-2638,2641,2642,2655,2656 | PN6~PN100 | DN10 ~ DN4000 |

| Australian Standard | AS2129 | Table: T/A, T/D, T/E, T/F, T/H, T/J, T/K, T/R, T/S, T/T | DN15 ~ DN3000 |

| AS4087 | PN16 ~ PN35 | DN50 ~ DN1200 | |

| British Standard | BS4504 | PN2.5 ~ PN40 | DN10 ~ DN4000 |

| BS10 | T/A, T/D, T/E, T/F, T/H | 1/2" ~ 48" | |

| Japanese Standard | JIS B2220 | 5K ~ 30K | DN10 ~ DN1500 |

| API Standard | API 6A, 11D | 2000 PSI ~ 20000 PSI | 1 13/16" ~ 30" |

| French Standard | NFE 29203 | PN2.5 ~ PN420 | DN10 ~ DN600 |

MATERIAL Of Stainless Steel Flange

| Stainless Steel | ||

| Material Standard | Material Grade | |

| ASTM | ASTM A182 | F304 / F304 L |

| ASTM A182 | F316/ F316L | |

| ASTM A182 | F310, F321 | |

| ASTM A182 | F321 | |

| DIN EN | DIN EN 10222-5 | EN 1.4301 |

| DIN EN 10222-5 | EN 1.4404 | |

| JIS | JIS G3214 | SUS F304 |

| JIS G3214 | SUS F304L | |

| JIS G3214 | SUS F316 | |

| JIS G3214 | SUS F316L | |

- Q: How do you prevent steel pipes from rusting?

- Various measures can be taken to prevent the rusting of steel pipes. One effective method is the application of a protective coating on the surface of the pipes. Different types of coatings, such as paint, epoxy, or zinc, can be used for this purpose. These coatings act as a barrier between the steel and the corrosive environment, thereby preventing direct contact between moisture, oxygen, and the metal, which can lead to rust formation. Another approach involves the use of corrosion inhibitors. These substances are added to the water or fluid flowing through the pipes, creating a protective film on the surface of the steel. This film acts as a shield, inhibiting the corrosion process and preventing the formation of rust. Regular maintenance plays a crucial role in preventing rust on steel pipes. It is essential to inspect the pipes regularly for any signs of damage or corrosion and promptly repair or replace any compromised areas. Additionally, keeping the pipes clean and dry by removing accumulated dirt or moisture helps prevent the formation of rust. In some cases, using stainless steel pipes instead of regular steel can be beneficial. Stainless steel contains chromium, which forms a passive oxide layer on the metal's surface. This layer acts as a natural barrier against corrosion, making stainless steel pipes highly resistant to rust. Finally, controlling the installation environment of the pipes can also help prevent rust. This can be achieved by maintaining proper ventilation, controlling humidity levels, and avoiding exposure to harsh chemicals or corrosive substances. By implementing these preventive measures, the lifespan and integrity of steel pipes can be significantly extended, while minimizing the risk of rust formation.

- Q: Are steel pipes suitable for underground compressed air systems?

- Yes, steel pipes are generally suitable for underground compressed air systems. Steel pipes have several advantages that make them a popular choice for such applications. Firstly, steel pipes are known for their high strength and durability, which allows them to withstand the pressure and stress associated with compressed air systems. They can handle high operating pressures without any significant risk of bursting or leaking. Secondly, steel pipes have excellent resistance to corrosion and can withstand exposure to moisture, soil, and other underground elements. This makes them a reliable choice for underground installations, where pipes may be exposed to moisture and other potentially corrosive substances. Furthermore, steel pipes are relatively easy to install and maintain. They can be welded or threaded together, ensuring a secure and leak-free connection. Additionally, steel pipes can be easily inspected and repaired if necessary, allowing for cost-effective maintenance and repairs. However, it is important to note that the suitability of steel pipes for underground compressed air systems may also depend on other factors such as the specific requirements and conditions of the system. It is advisable to consult with a professional engineer or a qualified expert to ensure that steel pipes are the most appropriate choice for a specific application.

- Q: What are the common sizes of steel pipes?

- Common sizes of steel pipes can vary depending on the application, but some common sizes include 1/2 inch, 3/4 inch, 1 inch, 1.5 inches, 2 inches, 3 inches, 4 inches, 6 inches, 8 inches, 10 inches, and 12 inches in diameter.

- Q: How do steel pipes perform in extreme weather conditions?

- Steel pipes are highly resilient and perform exceptionally well in extreme weather conditions. They have excellent resistance to corrosion, impact, and temperature variations, making them ideal for withstanding harsh environments such as extreme heat, cold, and heavy rainfall. Moreover, steel pipes are known for their durability and strength, ensuring that they can withstand the forces exerted by high winds, snow, and even seismic activities. Overall, steel pipes are a reliable choice for various applications in extreme weather conditions.

- Q: How are steel pipes used in the manufacturing of oil refineries?

- Steel pipes are used in oil refineries for a variety of purposes, including transporting crude oil and other fluids, as well as for structural applications. They are commonly used for piping systems, carrying process fluids such as oil, gas, and water, throughout the refinery. Additionally, steel pipes are used to handle corrosive and high-pressure environments, making them essential for the safe and efficient operation of oil refineries.

- Q: What are the different types of joints used to connect steel pipes?

- There are several types of joints commonly used to connect steel pipes, including threaded joints, flanged joints, welded joints, and mechanical joints. Each type of joint has its own advantages and is chosen based on factors such as the application, pipe size, and pressure requirements.

- Q: Is there any difference between thermal expansion seamless steel pipe and seamless steel pipe?

- Differ,Thermal expansion seamless steel tube is what we often call "thermal expansion tube", the density is relatively low, but a strong contraction of the steel pipe, (seamless steel pipe) can be referred to as "heat expansion.". A finishing rolling process for pipe rolling by using oblique rolling or drawing method to enlarge pipe diameter. In a relatively short period of time, the outer diameter of the steel pipe becomes larger, and the seamless tube with nonstandard and special type can be produced, and the cost is lower and the production efficiency is high, which is the development trend of the international rolling tube field at present.

- Q: What are the factors affecting the lifespan of steel pipes?

- The lifespan of steel pipes can be influenced by several factors. 1. Corrosion is a primary factor that can considerably diminish the lifespan of steel pipes. Over time, exposure to moisture, chemicals, and other corrosive elements can result in rusting and degradation of the pipe material. 2. The environment in which the steel pipes are installed plays a vital role in their longevity. Extreme temperatures, humidity, and exposure to various weather conditions can expedite the corrosion process and weaken the pipe structure. 3. The quality of the water flowing through the steel pipes can also affect their lifespan. Water with high levels of acidity or alkalinity, excessive chlorine, or other contaminants can cause corrosion and deterioration of the pipe material. 4. The way steel pipes are installed can impact their lifespan. Poor installation practices, such as inadequate support or incorrect alignment, can create stress points and structural weaknesses, making the pipes more susceptible to failure. 5. Regular maintenance and timely repairs are crucial for maximizing the lifespan of steel pipes. Proper cleaning, inspection, and corrosion protection measures can help identify and address potential issues before they escalate and cause significant damage. 6. The design and quality of steel used in pipe manufacturing are important factors in determining their lifespan. High-quality steel with appropriate alloy composition and thickness provides better resistance to corrosion and mechanical stress, ensuring a longer lifespan. 7. The durability of steel pipes can be influenced by the load and pressure they are subjected to. Excessive pressure or frequent variations in pressure can stress the pipe walls, leading to fatigue or failure over time. By considering and addressing these factors, it is possible to extend the lifespan of steel pipes and ensure their reliable performance over an extended period of time.

- Q: What are low-pressure carbon steel tubes?

- Any of various steels that contain less than 2.11% of the mass of carbon but contain no alloying elements. Sometimes referred to as plain carbon steel or carbon steel.Carbon steel, in addition to carbon, usually contains a small amount of silicon, manganese, sulfur and phosphorus.1) according to the use of carbon steel can be divided into carbon structural steel, carbon tool steel and easy to cut structural steel three categories, carbon structural steel is divided into engineering construction steel and machine manufacturing structural steel two kinds;(2) by refining methods can be divided into open hearth steel, converter steel;(3) according to deoxidization methods, they can be divided into boiling steel (F), killed steel (Z), semi killed steel (b) and special killed steel (TZ);(4) according to the carbon content of the steel can be divided into low carbon steel (WC = 0.25%), carbon steel (WC0.25% - 0.6%) and high carbon steel (WC>0.6%);(5) according to the quality of steel, carbon steel can be divided into ordinary carbon steel (phosphorus, sulfur, higher), high quality carbon steel (low phosphorus and sulfur) and high quality steel (lower phosphorus and sulfur) and super quality steel.Description: the carbon content in general carbon steel is higher, the hardness is higher, the strength is higher, but the plasticity is lower.

- Q: What are the different types of steel pipes available in the market?

- In the market, one can find a variety of steel pipes, each designed for specific purposes and applications. Some of the commonly used types are as follows: 1. Carbon Steel Pipes: These pipes are widely utilized due to their strength and durability. They are primarily employed in industries like oil and gas, construction, and plumbing for fluid and gas transportation. 2. Alloy Steel Pipes: By combining carbon steel with different metals like chromium, nickel, or molybdenum, alloy steel pipes offer enhanced strength, corrosion resistance, and heat resistance. They find applications in high-pressure environments such as power plants and chemical plants. 3. Stainless Steel Pipes: Highly resistant to corrosion and oxidation, stainless steel pipes are suitable for applications requiring hygiene and durability. Industries like food processing, pharmaceuticals, and water treatment commonly use them. 4. Galvanized Steel Pipes: These pipes are coated with a layer of zinc to protect against rust and corrosion. They are commonly found in plumbing systems and structures like fences and handrails. 5. Seamless Steel Pipes: These pipes are manufactured without any welding or joints, resulting in a smooth and continuous surface. They are known for their high strength and are often used in high-pressure applications. 6. Welded Steel Pipes: Made by rolling or bending a flat steel plate into a cylindrical shape and welding the edges together, welded pipes find common usage in construction, oil and gas, and automotive industries. 7. ERW (Electric Resistance Welded) Steel Pipes: ERW pipes are produced by passing a high-frequency electrical current through a steel strip, causing it to heat and form a weld. They are widely utilized in plumbing, water wells, and structural support. 8. LSAW (Longitudinal Submerged Arc Welded) Steel Pipes: LSAW pipes are created by bending and welding steel plates into a cylindrical shape. They are commonly employed for long-distance transportation of large volumes of oil, gas, or water. These examples represent only a fraction of the diverse range of steel pipes available in the market. The choice of the appropriate pipe type depends on factors such as the intended application, environmental conditions, and budget constraints. Consulting with experts or professionals is crucial in determining the most suitable steel pipe for a specific project or application.

Send your message to us

STAINLESS STEEL FORGED FLANGE 304/316 ASME B16.5 WELDING NECK

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords