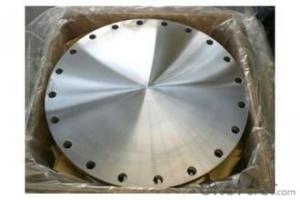

STAINLESS STEEL PIPE FORGED FLANGES 304/316L ANSI B16.5

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Package Of Stainless Steel Flange:

PACKED IN PLYWOOD CASES OR PALLETS

Painting Of Stainless Steel Flange:

ANTI-RUST OIL

Marking Of Stainless Steel Flange:

REFER TO MARKING DOCUMENT or AS PER CUSTOMER REQUEST

Shipping Marks Of Stainless Steel Flange:

EACH WOODEN BOX TWO PLASTIC SHIPPING MARKS

Specification Of Stainless Steel Flange:

Carbon Steel Flange Slip On Flange, Plate Flange, Blind Flange, Welding Neck Flange, Socket Welded Flange, Thread Flange, Lap Joint Flange, Long Welding Neck Flange

Size : 1/2"-48"

Wall Thickness.: SCH10-SCH160, SGP , XS, XXS, DIN ,STD

| Name | Stainless Steel Flange |

| Size | 1/2" - 48" |

| Face | RF, FF, RTJ |

| Wall thickness | Sch5-Sch160 XXS,STD,XS, SGP |

| Standard | ASME B16.5, B16.47, BS4504, JIS B2220, API 6A, 11Detc. |

| We can also produce according to drawing and standards provided by customers. | |

| Material | 304, 304L, 316, 316L, 304/304L, 316/316L, EN1.4301, EN1.4404 etc. |

| Packaging | Wooden Cases, wooden pallet , or carton box , or nylog bag and then in wooden cases |

| Surface Treatment | Anti-rust Oil |

| Delivery Time | 20-30 days, after received advance payment. |

| Quality | 100% Heat Treatment, No Welding repair |

| Others | 1.Special design available according to your drawing. |

| 2.anti-corrosion and high-temperature resistant with black painting | |

| 3. All the production process are made under the ISO9001:2000 strictly. | |

| 4. A conformity rate of ex-factory inspection of products. | |

| 5. we have export right , offering FOB , CNF CIF price |

STANDARD & MATERIAL GRADE

STAMDARD Of Stainless Steel Flange

<table style="WIDTH: 838px" cellspaci

- Q: Are steel pipes affected by UV rays?

- Yes, steel pipes can be affected by UV rays. Prolonged exposure to UV radiation can lead to the degradation of the protective coatings on steel pipes, causing them to corrode and weaken over time. It is important to implement proper protective measures, such as applying UV-resistant coatings or using protective covers, to mitigate the impact of UV rays on steel pipes.

- Q: How much is the wall thickness standard of building 48?

- According to the "construction of fastener type steel pipe scaffold safety technical specifications JGJ130-2011" stipulates that the specification of steel pipe should be Phi 48.3 * 3.6, that is, wall thickness is 3.6mm.

- Q: What are the common methods for repairing steel pipes?

- Depending on the nature and extent of the damage, there are several common methods available for repairing steel pipes. One method frequently used is welding. This technique involves melting the damaged area and fusing it with a new piece of steel. Welding is typically employed for small cracks or holes in the pipe. Different welding techniques, such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), or tungsten inert gas (TIG) welding, can be utilized. Another option is pipe wrapping or bandaging. This method entails wrapping a layer of adhesive tape or resin-soaked fiberglass around the damaged section of the pipe. It is suitable for addressing small leaks or corrosion spots and serves as a temporary solution until a more permanent fix can be implemented. If the damage is extensive or the pipe suffers severe corrosion, pipe lining or relining may be necessary. This involves inserting a new pipe liner inside the existing one, effectively creating a new pipe within the old one. Various materials, such as epoxy, polyethylene, or cured-in-place pipe (CIPP), can be used for this method. Pipe lining is commonly employed for larger diameter pipes or when replacement is not feasible. In some instances, minor leaks or cracks can be repaired using pipe clamps or sleeves. These devices are designed to be clamped around the damaged section and can provide either a temporary or permanent solution, depending on the severity of the damage. Ultimately, the choice of repair method depends on factors such as the extent of the damage, accessibility of the damaged area, budget constraints, and the required long-term durability. It is advisable to consult with a professional pipe repair specialist to assess the specific situation and determine the most suitable method for repairing steel pipes.

- Q: What are the different methods of protecting steel pipes from external damage?

- There are several methods of protecting steel pipes from external damage, including coating the pipes with a corrosion-resistant material such as epoxy or polyethylene, applying a layer of protective tape, installing a cathodic protection system, using concrete or rock shielding, and implementing measures to prevent soil movement or impact damage.

- Q: How do steel pipes compare to other types of piping materials?

- Steel pipes are known for their exceptional strength, durability, and resistance to corrosion, making them superior to many other types of piping materials. They can withstand high pressure and temperature, making them suitable for a wide range of applications. Additionally, steel pipes are cost-effective, readily available, and easily recyclable, making them a preferred choice in various industries.

- Q: What are the different methods of cleaning steel pipes?

- There are several methods for cleaning steel pipes, including mechanical cleaning, chemical cleaning, and high-pressure water jetting.

- Q: What is the role of steel pipes in HVAC systems?

- Steel pipes play a crucial role in HVAC systems as they are used to transport hot or cold water, steam, and refrigerant gases throughout the system. They provide a durable and reliable conduit for the flow of fluids, ensuring efficient heating, cooling, and ventilation in buildings. Additionally, steel pipes are resistant to corrosion and can withstand high pressure, making them ideal for HVAC applications.

- Q: How are steel pipes tested for quality and strength?

- Steel pipes are tested for quality and strength through various methods, including destructive and non-destructive testing. Destructive tests involve subjecting samples to extreme conditions such as tension, compression, or bending to assess their mechanical properties. Non-destructive tests, on the other hand, utilize techniques like ultrasonic inspection, magnetic particle testing, and radiographic examination to detect any defects or anomalies without damaging the pipes. These rigorous testing procedures ensure that steel pipes meet the required standards and can withstand the intended applications.

- Q: Can steel pipes be used for chemical storage tanks?

- No, steel pipes are not suitable for chemical storage tanks as they are not designed to handle the corrosive nature of many chemicals.

- Q: What are the different testing methods used for steel pipes?

- To ensure the quality and reliability of steel pipes, various testing methods are employed. These methods include: 1. Non-destructive Testing (NDT): Ultrasonic testing, magnetic particle inspection, and liquid penetrant testing are utilized in NDT to identify surface or subsurface defects in steel pipes without causing any damage. 2. Mechanical Testing: Mechanical testing encompasses various tests to evaluate the mechanical properties of steel pipes, such as tensile strength, yield strength, elongation, hardness, and impact resistance. These tests determine the structural integrity and performance of the pipes. 3. Hydrostatic Testing: This method involves subjecting steel pipes to high-pressure water to assess their ability to withstand expected operating conditions. The pipes are filled with water and pressurized to a predetermined level for a specified duration. Any leaks or deformations are detected during this test. 4. Dimensional Inspection: This testing method ensures that steel pipes meet specified dimensional requirements. It involves measuring critical dimensions such as diameter, wall thickness, and length to verify compliance with applicable standards. 5. Visual Inspection: Trained inspectors visually assess the external appearance of steel pipes using this basic method. They examine the pipes for surface defects such as cracks, corrosion, or irregularities in shape or finish. 6. Chemical Analysis: Chemical analysis is conducted to determine the composition and elemental content of steel pipes. It ensures that the pipes are made from the correct grade of steel and meet required chemical composition standards. 7. Metallographic Examination: Metallography involves examining the microstructure of steel pipes under a microscope to evaluate their quality and integrity. It helps identify internal defects like grain boundaries, inclusions, or improper heat treatment that may impact overall performance. By employing these testing methods, manufacturers and inspectors can guarantee that steel pipes meet necessary quality standards and are suitable for their intended applications.

Send your message to us

STAINLESS STEEL PIPE FORGED FLANGES 304/316L ANSI B16.5

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords