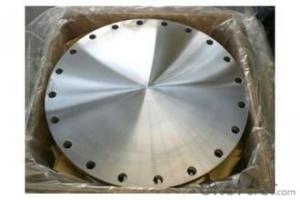

STAINLESS STEEL PIPE FORGED FLANGES 304/316 ANSI B16.5 best price good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Package Of Stainless Steel Flange:

PACKED IN PLYWOOD CASES OR PALLETS

Painting Of Stainless Steel Flange:

ANTI-RUST OIL

Marking Of Stainless Steel Flange:

REFER TO MARKING DOCUMENT or AS PER CUSTOMER REQUEST

Shipping Marks Of Stainless Steel Flange:

EACH WOODEN BOX TWO PLASTIC SHIPPING MARKS

Specification Of Stainless Steel Flange:

Carbon Steel Flange Slip On Flange, Plate Flange, Blind Flange, Welding Neck Flange, Socket Welded Flange, Thread Flange, Lap Joint Flange, Long Welding Neck Flange

Size : 1/2"-48"

Wall Thickness.: SCH10-SCH160, SGP , XS, XXS, DIN ,STD

| Name | Stainless Steel Flange |

| Size | 1/2" - 48" |

| Face | RF, FF, RTJ |

| Wall thickness | Sch5-Sch160 XXS,STD,XS, SGP |

| Standard | ASME B16.5, B16.47, BS4504, JIS B2220, API 6A, 11Detc. |

| We can also produce according to drawing and standards provided by customers. | |

| Material | 304, 304L, 316, 316L, 304/304L, 316/316L, EN1.4301, EN1.4404 etc. |

| Packaging | Wooden Cases, wooden pallet , or carton box , or nylog bag and then in wooden cases |

| Surface Treatment | Anti-rust Oil |

| Delivery Time | 20-30 days, after received advance payment. |

| Quality | 100% Heat Treatment, No Welding repair |

| Others | 1.Special design available according to your drawing. |

| 2.anti-corrosion and high-temperature resistant with black painting | |

| 3. All the production process are made under the ISO9001:2000 strictly. | |

| 4. A conformity rate of ex-factory inspection of products. | |

| 5. we have export right , offering FOB , CNF CIF price |

STANDARD & MATERIAL GRADE

STAMDARD Of Carbon Steel Flange

| Standard | Pressure | Size | |

| European Standard | EN 1092-1 | Class PN6 ~ PN100 | DN10 ~ DN4000 |

| American Standard | ASME B16.5 | Class 150 ~ 2500 | 1/2" ~ 24" |

| ASME B16.47A | Class 150 ~ 900 | 26" ~ 60" | |

| ASME B16.47B | Class 75 ~ 900 | 26" ~ 60" | |

| German Standard | DIN 2527,2566,2573, 2576, 2627-2638,2641,2642,2655,2656 | PN6~PN100 | DN10 ~ DN4000 |

| Australian Standard | AS2129 | Table: T/A, T/D, T/E, T/F, T/H, T/J, T/K, T/R, T/S, T/T | DN15 ~ DN3000 |

| AS4087 | PN16 ~ PN35 | DN50 ~ DN1200 | |

| British Standard | BS4504 | PN2.5 ~ PN40 | DN10 ~ DN4000 |

| BS10 | T/A, T/D, T/E, T/F, T/H | 1/2" ~ 48" | |

| Japanese Standard | JIS B2220 | 5K ~ 30K | DN10 ~ DN1500 |

| API Standard | API 6A, 11D | 2000 PSI ~ 20000 PSI | 1 13/16" ~ 30" |

| French Standard | NFE 29203 | PN2.5 ~ PN420 | DN10 ~ DN600 |

MATERIAL Of Carbon Steel Flange

| Carbon Steel | ||

| Material Standard | Material Grade | |

| ASTM | ASTM A105 | A105, A105N |

| ASTM A350 | A350 LF1, LF2 | |

| ASTM A182 | F11, F12, F22 | |

| ASTM A106 | A, B, C | |

| DIN EN | DIN17175 | St35.8, St45.8, 15Mo3 |

| EN10216-2 | 195GH,P235GH, P265GH, 20MnNb6 | |

| JIS | JIS G3461 | STB340,410,510 |

| JIS G3462 | STBA12, 13, 20, 22, 23, 24 | |

| JIS G3454,G3455,G3456 | STPG 370, STB410, STS370,410, 510 | |

| STPT 370, 410, 480 | ||

- Q: Can steel pipes be used for underground oil pipelines?

- Indeed, underground oil pipelines can utilize steel pipes. The construction of underground oil pipelines heavily relies on steel pipes owing to their robustness, longevity, and resistance to corrosion. They possess the capability to endure the immense pressure and weight exerted by the oil being transported, along with external forces like soil displacement or seismic events. Moreover, steel pipes can be fortified with coatings or linings such as epoxy or polyethylene, enhancing their resistance to corrosion and extending their lifespan. In conclusion, steel pipes emerge as a dependable and extensively employed option for underground oil pipelines.

- Q: Who knows what is the difference between double submerged arc welded pipe and longitudinal submerged arc welding?

- Double submerged arc welding should be for spot welding and single side welding, they are straight line welds, but double submerged arc welding seam is more beautiful and fine.

- Q: When can I use the PVC pipe and when to use the galvanized pipe?

- Galvanized pipes are generally used outside the drying environment or building blocks, and PVC is mainly used for pre embedding in walls or humid environments. If in the ceiling ceiling, below the roof, you need to use galvanized pipe, in the floor below, on the ground you need to use PVC.

- Q: How are steel pipes used in the manufacturing of HVAC systems?

- Steel pipes are commonly used in the manufacturing of HVAC systems for various purposes. They are used to transport fluids, such as water or refrigerants, throughout the system. Steel pipes are also used for exhaust systems and ventilation, providing a durable and corrosion-resistant solution. Additionally, steel pipes are used in the construction of HVAC equipment, such as heat exchangers and boilers, due to their strength and ability to withstand high temperatures and pressures. Overall, steel pipes play a crucial role in the efficient and reliable functioning of HVAC systems.

- Q: What is the maximum temperature that steel pipes can withstand?

- The maximum temperature that steel pipes can withstand depends on the grade and type of steel used. Generally, carbon steel pipes can withstand temperatures up to 1000°C (1832°F), while stainless steel pipes can handle temperatures up to 1200°C (2192°F). However, it is essential to consult the specific specifications and guidelines provided by the manufacturer for accurate temperature limits.

- Q: How are steel pipes used in the mining and mineral processing industry?

- Steel pipes are commonly used in the mining and mineral processing industry for various purposes such as transporting liquids, gases, and slurries, as well as providing structural support for mining infrastructure. These pipes are highly durable and resistant to corrosion, making them suitable for harsh and demanding environments. They are used for tasks such as transporting water for mining operations, carrying tailings and waste materials, and conveying mining chemicals. Additionally, steel pipes are utilized in the construction of mine shafts, tunnels, and processing plants, providing a strong and reliable framework for mining operations.

- Q: What are the different coating options available for steel pipes?

- There are several coating options available for steel pipes, including fusion bonded epoxy (FBE) coating, polyethylene (PE) coating, polyurethane (PU) coating, and zinc coating. Each coating provides different levels of protection against corrosion and abrasion, and the choice depends on the specific application and environmental conditions.

- Q: What are the factors to consider when selecting pipe materials for corrosive environments?

- To ensure the longevity and effectiveness of a piping system in corrosive environments, several important factors must be considered. Firstly, the corrosion resistance of the pipe material is crucial. It is essential to select a material highly resistant to corrosion as time can cause significant damage to pipes in corrosive environments. Stainless steel, fiberglass, PVC, and CPVC are materials known for their excellent corrosion resistance. Secondly, the chemical compatibility of the pipe material with the corrosive environment should be assessed. Different materials have varying resistance levels to different chemicals, so it is important to ensure that the chosen material can withstand the specific chemicals present. Consulting chemical compatibility charts and seeking expert advice can aid in selecting the right material. Furthermore, the temperature and pressure requirements within the corrosive environment should be taken into account. Some materials have limitations in terms of temperature and pressure resistance, exceeding which can lead to pipe failure. It is crucial to choose a material that can handle the required temperature and pressure ranges without compromising its structural integrity. The cost of the pipe material and its installation should also be considered. While certain materials may offer high corrosion resistance, they may also be more expensive. Striking a balance between the desired level of corrosion resistance and the available budget is essential. Lastly, the maintenance requirements and overall durability of the pipe material should be evaluated. Some materials may require more frequent inspections, cleaning, or repairs compared to others. Considering the anticipated lifespan of the piping system and the ease of maintenance can help in selecting a material that ensures long-term reliability and cost-effectiveness. In conclusion, when selecting pipe materials for corrosive environments, it is important to consider factors such as corrosion resistance, chemical compatibility, temperature and pressure requirements, cost, and maintenance and durability. By carefully evaluating these factors, one can choose a pipe material that best suits the specific corrosive environment and ensures a reliable and long-lasting piping system.

- Q: What industries typically use steel pipes?

- Steel pipes find widespread use across various industries due to their durability, strength, and versatility. Some of the sectors that typically employ steel pipes include: 1. Construction: Steel pipes are extensively utilized in the construction industry for diverse purposes like structural support, plumbing, and underground piping systems. They are commonly seen in commercial buildings, residential structures, bridges, and tunnels. 2. Oil and gas: The oil and gas industry heavily relies on steel pipes for drilling, transporting, and distributing oil and gas. Steel pipes are employed in offshore drilling rigs, oil refineries, natural gas processing plants, and pipelines to ensure the safe and efficient transport of these valuable resources. 3. Water and wastewater: Steel pipes play a crucial role in providing clean water supply and managing wastewater. They are used in water treatment plants, desalination facilities, and municipal water distribution systems. Steel pipes are also essential for sewage and stormwater management. 4. Manufacturing: Various manufacturing industries employ steel pipes for specific applications. For example, automobile manufacturers use steel pipes in exhaust systems, fuel lines, and hydraulic systems. Steel pipes are also utilized in the production of machinery, equipment, and appliances. 5. Mining: The mining industry requires robust and enduring materials for its operations. Steel pipes are used in mining applications such as conveying materials, ventilation systems, and underground infrastructure. They prove particularly useful in transporting minerals, ores, and other mining byproducts. 6. Energy and power: Steel pipes find extensive use in power generation facilities, including thermal power plants, nuclear power plants, and renewable energy installations. They are employed in steam pipelines, cooling systems, and heat exchangers. Steel pipes are also used in the construction of transmission lines for electricity distribution. 7. Infrastructure and transportation: Steel pipes are essential for infrastructure development and transportation systems. They are used in the construction of roads, bridges, railways, and airports. Steel pipes also play a role in the transportation of fluids and gases, such as in natural gas or petroleum product pipelines. Overall, the versatility and dependability of steel pipes make them indispensable in a wide range of industries, contributing to various aspects of our modern infrastructure and daily lives.

- Q: What are the different methods of heat treatment for steel pipes?

- Some of the different methods of heat treatment for steel pipes include annealing, quenching, tempering, normalizing, and stress relieving.

Send your message to us

STAINLESS STEEL PIPE FORGED FLANGES 304/316 ANSI B16.5 best price good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords