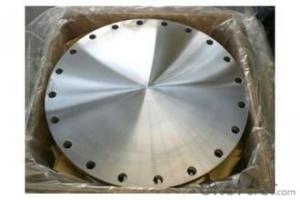

STAINLESS STEEL PIPE FORGED FLANGES 304/316 ANSI B16.5 BEST PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Package Of Stainless Steel Flange:

PACKED IN PLYWOOD CASES OR PALLETS

Painting Of Stainless Steel Flange:

ANTI-RUST OIL

Marking Of Stainless Steel Flange:

REFER TO MARKING DOCUMENT or AS PER CUSTOMER REQUEST

Shipping Marks Of Stainless Steel Flange:

EACH WOODEN BOX TWO PLASTIC SHIPPING MARKS

Specification Of Stainless Steel Flange:

Carbon Steel Flange Slip On Flange, Plate Flange, Blind Flange, Welding Neck Flange, Socket Welded Flange, Thread Flange, Lap Joint Flange, Long Welding Neck Flange

Size : 1/2"-48"

Wall Thickness.: SCH10-SCH160, SGP , XS, XXS, DIN ,STD

| Name | Stainless Steel Flange |

| Size | 1/2" - 48" |

| Face | RF, FF, RTJ |

| Wall thickness | Sch5-Sch160 XXS,STD,XS, SGP |

| Standard | ASME B16.5, B16.47, BS4504, JIS B2220, API 6A, 11Detc. |

| We can also produce according to drawing and standards provided by customers. | |

| Material | 304, 304L, 316, 316L, 304/304L, 316/316L, EN1.4301, EN1.4404 etc. |

| Packaging | Wooden Cases, wooden pallet , or carton box , or nylog bag and then in wooden cases |

| Surface Treatment | Anti-rust Oil |

| Delivery Time | 20-30 days, after received advance payment. |

| Quality | 100% Heat Treatment, No Welding repair |

| Others | 1.Special design available according to your drawing. |

| 2.anti-corrosion and high-temperature resistant with black painting | |

| 3. All the production process are made under the ISO9001:2000 strictly. | |

| 4. A conformity rate of ex-factory inspection of products. | |

| 5. we have export right , offering FOB , CNF CIF price |

STANDARD & MATERIAL GRADE

STAMDARD Of Stainless Steel Flange

<table style="WIDTH: 838px" cellspaci

- Q: What are the different methods of pipe protection for steel pipes?

- There are several different methods of pipe protection for steel pipes, each serving a unique purpose and providing varying levels of protection. Some of the common methods include: 1. Coatings: Coatings are applied on the external surface of steel pipes to protect them from corrosion and other environmental factors. Coating materials can include various types of paints, epoxies, or polymers. These coatings create a barrier between the pipe surface and the surrounding environment, preventing the steel from coming into contact with corrosive elements. 2. Wrapping: Wrapping involves using a protective material, such as tape or shrink wrap, to cover the steel pipe. This method provides a physical barrier against moisture, chemicals, and other corrosive substances. Wrapping is often used in combination with coatings to enhance the overall protection. 3. Cathodic Protection: Cathodic protection is an electrochemical method used to protect steel pipes from corrosion. It involves connecting the steel pipe to a sacrificial anode, typically made of zinc or magnesium. The anode corrodes instead of the pipe, which helps to prevent the steel from deteriorating. This method is commonly used for buried or submerged pipelines. 4. Thermal Insulation: Thermal insulation is used to protect steel pipes from extreme temperatures. Insulating materials, such as foam or mineral wool, are applied around the pipe to minimize heat transfer. This method is particularly important for pipes carrying hot fluids or exposed to extreme weather conditions. 5. Vibration Dampening: Vibration can cause stress and fatigue on steel pipes, leading to potential damage. To protect against vibrations, various techniques can be employed, such as using vibration damping pads or installing supports and clamps. These methods help to absorb and dissipate the energy generated by vibrations, reducing the risk of pipe failure. 6. Concrete Coating: For pipelines installed underwater or in highly corrosive environments, concrete coating is often used. A layer of concrete or a cement-based mortar is applied to the steel pipe, providing both mechanical protection and resistance to corrosion. It is important to select the appropriate method of pipe protection based on the specific application, environmental conditions, and desired level of protection. Regular inspection and maintenance are also crucial to ensure the long-term integrity of steel pipes.

- Q: Seamless steel pipe is how to do it?

- Seamless steel tube is a kind of steel strip with hollow section and without seams. A steel pipe having a hollow cross section, used as a conduit for conveying fluids, such as pipelines for transporting petroleum, natural gas, gas, water, and certain solid materials. Compared withsteel and roundsteelinsolid, flexural torsional strength in the same time, the weight is light, is a kind of economic section steel, widely used in the manufacture of structural parts and mechanical parts, such as the oil pipe, automobile transmission shaft, the bicycle frame and steel construction with scaffold. The manufacture of ring parts with steel tubes can improve material utilization, simplify manufacturing processes, save materials and work hours, such as rolling bearings, rings, Jack sleeves, etc., and have been widely used in steel pipes. Steel pipe or all kinds of conventional weapons indispensable materials, gun barrels are made of steel. The steel pipe can be divided into round tube and special-shaped pipe according to the sectional area shape. Because the circle area is the largest under the condition of equal circumference, more fluid can be transported with round tubes. In addition, the ring section in the internal or external radial pressure is more uniform force, so most of the steel pipe is round tube.

- Q: What is the pressure rating of steel pipes?

- The pressure rating of steel pipes varies depending on its size, wall thickness, and the type of steel used. It can range from a few hundred pounds per square inch (psi) for smaller pipes to several thousand psi for larger ones.

- Q: 304 stainless steel tube with the diameter of 25*2-3 is what mean

- This is according to the "water drawing standards" (GBT50106-2001) in 2.4.2-2 seamless steel pipe, welded steel pipe (straight or spiral seam), brass, stainless steel pipe, pipe diameter should be D diameter * thickness representation (such as D108 * 4 and D159 * 4.5); and the provisions of the habit of acting D with seamless pipe diameter.

- Q: Can steel pipes be used for automotive applications?

- Yes, steel pipes can be used for automotive applications. Steel pipes are commonly used in the automotive industry for various purposes such as exhaust systems, fuel lines, and hydraulic systems. Steel pipes offer high strength, durability, and resistance to corrosion, making them suitable for withstanding the harsh conditions and demands of automotive applications. Additionally, steel pipes can be easily formed and welded, allowing for customization and ease of installation. Overall, steel pipes provide a reliable and cost-effective solution for automotive applications.

- Q: How are steel pipes protected against seismic activities?

- Steel pipes are protected against seismic activities through various measures. One common method is the use of seismic restraint systems, which include bracing, clamps, and supports that are designed to withstand the forces generated during an earthquake. Additionally, pipes can be coated with corrosion-resistant materials to enhance their durability and resistance to seismic events. Regular inspection and maintenance of the pipes are also essential to ensure their continued protection against seismic activities.

- Q: What are the different types of steel pipe fittings for plumbing systems?

- Some common types of steel pipe fittings used in plumbing systems include elbows, tees, unions, couplings, reducers, and caps. Elbows are used to change the direction of the pipe, while tees allow for branching off into multiple directions. Unions are used to join two pipes together, couplings are used to connect two pipes of the same diameter, and reducers are used to connect pipes of different diameters. Caps are used to seal the end of a pipe.

- Q: What are the factors affecting the durability of steel pipes?

- There are several factors that can affect the durability of steel pipes, including the quality of the steel used, the manufacturing process, the environment in which the pipes are installed, and the maintenance and care given to the pipes.

- Q: How are steel pipes used in plumbing systems?

- Steel pipes are commonly used in plumbing systems for their durability and strength. They are used to transport water, gas, and waste materials in both residential and commercial buildings. Steel pipes are known for their resistance to corrosion and high pressure, making them ideal for underground and outdoor applications. Additionally, steel pipes are often used for plumbing fixtures such as faucets, showers, and toilets, providing a reliable and long-lasting solution for water distribution and drainage.

- Q: What are the applications of steel pipes?

- Steel pipes are widely used in various industries and applications due to their exceptional strength, durability, and versatility. Some common applications of steel pipes include transportation of fluids and gases in oil and gas industry, water supply and drainage systems, structural support in construction projects, plumbing and heating systems, manufacturing of automobiles and machinery, and in the agricultural sector for irrigation and irrigation systems. Additionally, steel pipes are also used in the energy and power generation sector, chemical processing plants, and for underground and underwater installations.

Send your message to us

STAINLESS STEEL PIPE FORGED FLANGES 304/316 ANSI B16.5 BEST PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords