Stainless Steel Fiber factory direct sale

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons kg

- Supply Capability:

- 50000000 Ton Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

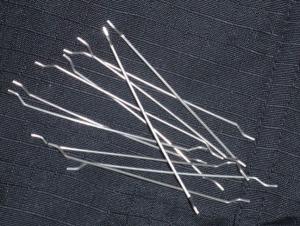

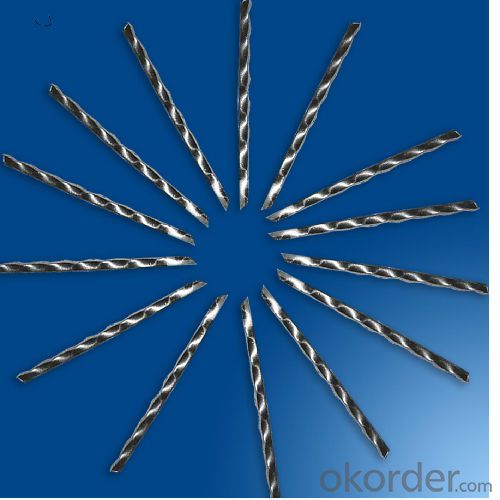

Description of Stainless Steel Fiber:

Sainless steel fiber is manufactured from coil by chopping the width of the stainless coil, it is used for precast shapes and castable project; It has uniform chemical composition and good dimensional stability.

APPLICATION of Stainless Steel Fiber:

stainless steel fiber is manufactured from coil by chopping the width of the stainless coil, it is used for precast shapes and castable project; It has uniform chemical composition and good dimensional stability.

ADVANTAGE of Stainless Steel Fiber:

---Anti-crack,

---Pressure-resistance

---Anti-abrasion

---Bending toughness

SPECIFICATION of Stainless Steel Fiber:

Grade | Chemical composition Content (%) | Melting point (℃) | Diameter (mm) | Tensile strength (MPa) | ||

Cr | Ni | Max | Average | |||

304 | 18-20 | 8-10 | 2550-2650 | 1800 | 0.5-1.0±0.04 | ≥1200 |

310 | 24-26 | 19-22 | 2550-2650 | 2100 | 0.5-1.0±0.04 | ≥1200 |

430 | 16-18 | ------- | 1425-1510 | 1400 | 0.5-1.0±0.04 | ≥1000 |

- Q: I am replacing a kitchen floor with tile. When I ripped up the existing floor there was plywood in great shape. Do I really need to lay cement board down beofre tiling? What could happen if I dont?

- I have neighbors that tried to cut a few corners and not lay the cement board. Floor looked fantastic after hours and hours of them carefully laying it and grouting. Floor look like hell in a year. Chipped cracked, loose and shifted tiles. They had to rip it all up and do it right...The second time due to how much they outlayed on the first tiles they put down the cement board and cheep fugly tiles. Never had an issue with them.

- Q: It's for my Science hw....

- Cement is not poisonous (since it is made from burnt stone) but I have never heard of anyone tempted to eat it. It is definitely not flammable (and is used for fireproofing over steel beams). If there is a great cloud of cement dust in the air in an area that has a source of ignition that dust could explode (not very common and only applies to the dust.) It is mildly corrosive when wet before it cures (only a problem during first few days after pouring it).

- Q: What color is the cement they use to put a permanent crown on. When I was flossing the other day this hard white stuff came out from between my teeth where the crown is. Could that be cement, should I be worried? That tooth had a root canal and a crown and the crown is sensitive when I eat hard foods on it.

- It is definately considered early, I have a crown as well and my cement is blue, the white that the floss got out was most likely plaque or something along those lines. A tenderness is to be expected this early on

- Q: And no, I'm not talking about rubber cement. I need to glue a multitude of hard rubberized toy dinosaurs to various urban materials, mainly concrete or cement. What would be the best glue to use with the strongest and longest lasting bond? Epoxy? And if so, what kind of epoxy?

- First of all, I have never seen a horse with rubber shoes. Only get aluminum if your horse is a really good mover. The aluminum is lightweight and is usually used by hunters so they can move with less knee action. However, aluminum is not as sturdy. Steel shoes are much better for your horse. If you show regularly you can get aluminum just for the show then switch back to steel, a ton of people do that. I get whatever shoe the farrier says, because that is what is best for your horse. My horse has a really slight clubbed hoof so we have to shoe him as if he has a quarter crack (even though he doesnt) just to be safe. It is not as much about the material of the shoe that factors how often your horse should get shod, it also depends on how quickly your horse's feet grow out.

- Q: I was putting together a process book for one of my classes and was gluing some work, using rubber cement, to paper and slipping it in plastic sleeves. A little while later I noticed that a lot of the plastic sleeves where warped where the rubber cement was. The plastic sleeves and rubber cement never made contact but it was warped where it was on the back of the paper. Does this normally happen? And if it does, is there a certain amount of time I should wait until I put the slips of paper into the plastic sleeves so it doesn't warp?

- Yes, Because rubber cement shrinks when it drys and hardens. I'd recommend laminating if you absolutely have to seal the sleeves, you can try way paper and an iron its worked for me before and any arts and crafts store like Michelle's should have real lamination sets at affordable prices.

- Q: how many cubic feet can i get out of 1 80lb bag of cement using sand and gravel???

- The actual cement required for concrete is affected by the choice of the maximum coarse aggregate size. As the maximum coarse aggregate size is decreased the cement content must increase to provide the required quantity of cement paste to coat all of the aggregate particles. Assume that the proportions will be made based on one part being a cubic foot (this is convenient since a 94 lb. bag of cement is 1 cubic foot of bulk material). For a 3/4 maximum coarse aggregate, the mixture would be 1 part portland cement, 2 1/2 parts sand, 2 1/2 parts coarse aggregate, and 1/2 part water. The sum of the parts is 6 ?. In general the final volume of concrete produced will be approximately 2/3 of the sum of all the volumes included in the mixture. Therefore the approximate volume of this concrete mixture is 4.3 cubic feet. If you adjust the above mixture based on a 80 lb. bag of cement, then you will produce 3.7 cu. ft. per bag approximately.

- Q: How a cement solution is prepared;;what is effect of quick setting of cement;;?

- cement is an ingredient in concrete. It sets with the chemical reaction of Calcium carbonate (limestone) and water to form a hard substance.

- Q: what's the difference between concrete and cement, and what are they used for?

- Cement is heat treated limestone. More properly called Portland Cement, after the guy who perfected the technique. Tho this stuff has been around for a very long time, used extensively by Roman Empire. The heating of the limestome drives off the water and allows a chemical reaction to take place when water is added. It gives off heat when curing. Concrete is cement with added stuff, aggragate and is used for many things. Most often seen as driveways and walls. Depending on what you add to it it can be used to make boats too.

- Q: what is the difference between cement and concrete ?

- Cement is a powdery part of the mix. Concrete is the solid, finished product.

- Q: I know they grab onto wood and trellis' but, do they need some kind of support to cover a cement wall?

- They wll grow with little support. I have seen them climb the side of a stucco house

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Lianyungang Port |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Stainless Steel Fiber factory direct sale

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons kg

- Supply Capability:

- 50000000 Ton Per Year kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords